Using the Drycake Twister to Recycle Gypsum Board to improve this eco-friendly waste management solution for plasterboard waste.

Did you know construction waste is a big problem? It makes up 10-15% of all materials used in building. This is much more than what experts usually say. Gypsum board is a big part of this waste, making it hard to get rid of.

Gypsum board, or plasterboard, is everywhere in modern buildings. It's light and easy to use for walls and ceilings. But getting rid of it is bad for the environment. It can release harmful gases when thrown away.

The Drycake Twister is a new way to recycle gypsum board. It's a game-changer for the construction world. It makes recycling easy and green, helping us all live better.

Let's look at how the Drycake Twister is changing how we handle waste. It's good for the planet and saves money too. Join us as we explore how to make construction more sustainable.

Key Takeaways

- Construction waste is a big problem, making up 10-15% of materials.

- Getting rid of gypsum board is bad for the environment.

- The Drycake Twister is a new way to recycle gypsum board.

- Recycling gypsum board is key to reducing harm to the environment.

- Using new recycling technologies is good for the planet and saves money.

For more info, visit Dyrcake Twister at https://twisterseparator.com or call +1-843-TWISTER.

Understanding the Importance of Gypsum Board Recycling

Gypsum board recycling is key to green building practices. It tackles the issue of 64% of gypsum waste from construction sites. This waste mainly comes from unused board scraps.

The Environmental Impact of Gypsum Waste

Throwing away gypsum board with general construction waste, or worse still with household waste, can harm the environment. It can release bad-egg smell gases and pollute soil liners in landfills. Recycling one tonne of gypsum saves 28 kWh of energy and cuts down on emissions.

Current Challenges in Gypsum Disposal

There are still hurdles in recycling gypsum board. Only about 10% of orders are custom-made, leading to a lot of waste. Also, old buildings might have lead paint, making recycling harder.

The Role of Responsible Waste Management

Managing gypsum board waste responsibly is vital for a green construction sector. The Construction & Demolition Recycling Association has set up a Gypsum Recycling Committee. Some recycling plants can use up to 30% recycled gypsum instead of new materials.

| Gypsum Waste Source | Percentage |

|---|---|

| Building Construction | 64% |

| Post-Consumer (Demolition) | 14% |

| Post-Consumer (Renovation) | 10% |

| Manufacturing | 12% |

By choosing eco-friendly gypsum board reuse and using recycling, the construction world can lessen its environmental footprint. This approach also brings many benefits from recycling gypsum board.

The Evolution of Gypsum Board Recycling Technology

The gypsum board recycling industry has made huge strides. As we worry more about the environment, finding good ways to recycle gypsum boards is key. Now, we have advanced technologies that help us get more out of the materials.

In the UK, British Gypsum is at the forefront. They've created a system where old plasterboard is turned into new sheets. This has cut down on waste and shows how the construction world can work in a circular way.

More homes and businesses are choosing gypsum boards for their safety and soundproofing. This need has driven the recycling tech forward. Today, recycling plants can handle many types of gypsum boards, even those with extra coatings.

“The gypsum board recycling industry is not just about waste reduction; it's about creating a sustainable future for construction,” says a spokesperson from the UK Gypsum Recycling Association.

Recent figures are encouraging:

- Approximately 734,000 tons of gypsum plasterboard waste was generated in Northern Europe alone in 2015.

- Studies show that making gypsum from recycled materials is better for the environment than using natural gypsum.

- Recycled gypsum keeps its quality for up to five recycling cycles.

The industry keeps getting better, thanks to new tech.

But, unfortunately, the skips and bags used to collect plasterboard waste are seldom, if ever, free from other contaminating items. If these are left in the waste when processed back into new plasterboard the product will fail its quality tests and be unusable. That's where a waste separator is needed.

Introducing the Drycake Twister: A Revolutionary Plasterboard Waste Separation Solution

The Drycake Twister is a groundbreaking solution for recycling gypsum board. It tackles the big problem of gypsum waste, which makes up about 12% of all construction and demolition debris.

The U.S. alone generates a staggering quantity of over 300 million tons of drywall waste every year. This makes finding good decontaminating solutions very important.

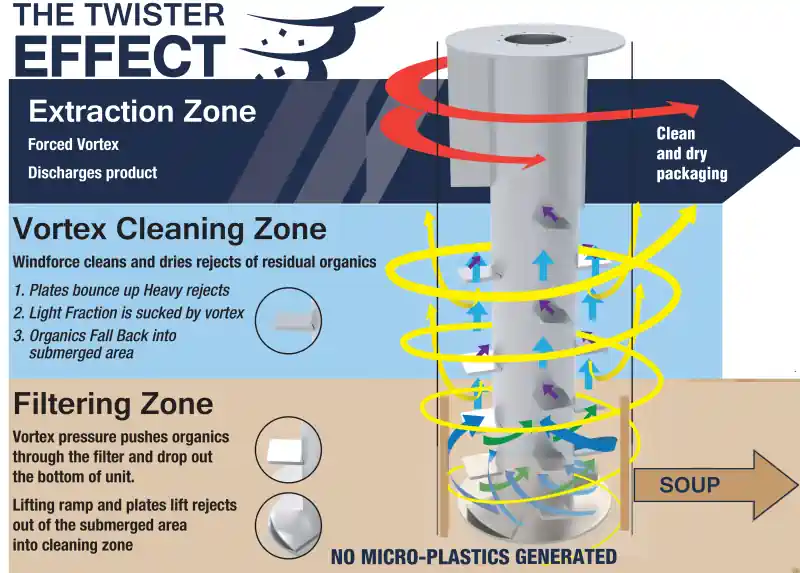

How the Vortex Separation Technology Works

The Drycake Twister uses advanced vortex separator technology to separate the plasterboard from the paper covering and any unwanted foreign materials. This machine very effectively separates gypsum particles from other materials. It does this by a combination of creating a cyclonic air flow combined with the action of short “bats” on the central vertical rotating spindle, achieving over 90% recovery rate for gypsum materials.

Key Features and Capabilities

The Drycake Twister separator has some amazing features:

- Reduces waste volume by up to 90%

- Processes multiple types of waste materials

- Completes batch processing in under one hour

- Operates with 30% higher energy efficiency compared to traditional methods

Technical Specifications and Performance Metrics

The Drycake Twister's performance is impressive:

| Metric | Value |

|---|---|

| Gypsum Recovery Rate | Over 90% |

| Waste Volume Reduction | Up to 90% |

| Processing Time per Batch | Under 1 hour |

| Energy Efficiency Improvement | 30% |

For more information, visit Drycake Twister or call +1-843-TWISTER.

The Step-by-Step Process of Recycling Gypsum Board

The gypsum board recycling process is key to eco-friendly disposal. It cuts down landfill use and saves resources.

It starts with collecting waste plasterboard. Sites can save £500 per skip by using a plasterboard waste scheme. This is cheaper than landfill costs of £2,000 per skip.

Next, the plasterboard is sorted to remove unwanted materials like metal and glass. This ensures the recycled product is of good quality.

- Collection and sorting of waste plasterboard

- Removal of contaminants for example by using a Twister Separator

- Grinding and separation of paper and gypsum

- Processing of gypsum powder

- Quality control checks

- Packaging and distribution of recycled gypsum

The Drycake Twister is a vital key in this process. It uses vortex technology to separate gypsum from the paper/ card on each face of the boards and also remove all unwanted items (known as the “reject stream”). This makes high-quality recycled gypsum.

| Component | Percentage | Recycling Potential |

|---|---|---|

| Gypsum | 90% | High |

| Paper | 10% | Moderate |

Using this recycling process, construction projects can lessen their environmental footprint. Recycled gypsum can be used to make up 10% to 20% of new drywall production. This supports a circular economy in construction.

Environmental Benefits of Professional Gypsum Recycling

Professional gypsum recycling is key for a greener future. It helps save landfills, cuts down on carbon emissions, and saves resources. These benefits are huge, going beyond just reducing waste.

Reduction in Landfill Usage

Using gypsum board again cuts down the waste that ends up in landfills. In the UK and EU, recycling plasterboard is a must to protect the environment. If not recycled properly, it can harm the air with toxic gases.

Carbon Footprint Minimisation

Making gypsum board uses less greenhouse gases than other building materials. Recycling it means even less carbon emissions. This helps lower the carbon footprint of building projects.

Resource Conservation Impact

Recycling gypsum board saves natural gypsum and cuts down mining. Using synthetic gypsum from cleaning smoke also helps the planet. Recycled gypsum can be used in many ways, like:

- New plasterboard production

- Cement manufacturing

- Agricultural solutions as a natural fertiliser

This approach not only saves resources but also offers cheaper options for farming and building. It shows how recycling gypsum board benefits us all.

Cost-Effective Waste Management for Construction Projects

Gypsum board waste management is now a big deal in the UK.

Since 2009, the Environmental Agency has banned landfilling of gypsum-based materials like plasterboard. This means people and businesses must separate and recycle plasterboard before throwing it away.

Professional recycling services offer affordable ways to manage construction waste. For example, HIPPO's plasterboard recycling costs just £35 per bag. This is for collecting 10 MIDIBAGs from one place and it's much cheaper than landfill charges that exceed £200/tonne including transport (2025), even for non-hazardous waste.

They make sure all the gypsum is recycled, following Environment Agency rules.

Managing gypsum board waste properly is key for legal reasons and to keep the environment safe. Mixing gypsum with regular waste can create harmful hydrogen sulfide gas. Also, plasterboard can't go in skips because general skip-hire companies usually won't take it.

| Aspect | Impact |

|---|---|

| Landfill Decomposition | Several decades, releasing sulfur dioxide |

| Resource Conservation | Recycling reduces demand for virgin gypsum |

| Greenhouse Gas Emissions | Effective recycling minimises landfill-associated emissions |

| Waste Reduction | Accurate measuring and efficient cutting techniques reduce wastage |

Using good recycling methods for gypsum board is not just about following the law. It also helps make construction more sustainable.

By using professional waste removal services, construction projects can recycle more plasterboard. This brings both environmental and economic gains.

Meeting UK Regulatory Requirements for Gypsum Disposal

The UK has strict rules for disposing of gypsum board. These rules help protect the environment and encourage eco-friendly disposal. Construction firms and waste management companies need to understand these regulations.

Current Legislative Framework

UK law requires special handling for gypsum waste. Since 2009, the Environmental Agency has banned mixing biodegradable waste with plasterboard in landfills. Now, landfills have special areas for plasterboard disposal. The rules are clear:

- Gypsum content above 10% needs mono-cell disposal

- Mixed skips can contain up to 10% plasterboard

- Asbestos-contaminated plasterboard is hazardous waste

Compliance and Certification

To ensure sustainable gypsum board disposal, businesses must follow these steps:

- Conduct a level 1 waste assessment

- Classify waste as hazardous or non-hazardous

- Document waste source and treatment

- Test for leaching behaviour

Proper certification is vital. The European Waste Catalogue (EWC) code must be used for all gypsum waste.

Future Regulatory Considerations

The UK's waste management strategy aims to boost recycling and reduce landfill use. Future regulations may tighten restrictions on gypsum disposal. Adopting eco-conscious gypsum board disposal methods now can help businesses stay ahead of evolving laws.

| Year | Paper Recycling Target | Glass Recycling Target | Aluminium Recycling Target |

|---|---|---|---|

| 2004 | 65% | 49% | 26% |

| 2008 | 70% | 71% | 35.5% |

Maximising Efficiency in Commercial Gypsum Board Processing

The gypsum board recycling industry has big challenges in managing waste well. Construction and demolition activities create 25-30% of all waste. So, making gypsum board processing more efficient is key for sustainable waste management.

Good recycling methods can really boost efficiency. By setting the right shredding parameters, production can go up by 40%. This means processors can handle more waste. Also, better shredder designs cut down on equipment downtime by 20-25%, making things more productive.

New technologies are crucial for better efficiency. Automated systems can make discharge 15-20% more efficient. Also, optimised shredding can increase material recovery by up to 30%. These gains are vital, as not optimising can cut throughput by 10-15%.

It's important to keep investing in research and development. Every year, shredding operations get about 10% better. This makes waste management more sustainable. Innovation is key, given gypsum plasterboard's wide use:

- House building: 30%

- Commercial Industrial: 30%

- Repair, Maintenance, Improvement: 40%

By using these efficient methods, the gypsum board recycling industry can greatly reduce waste. It can also save resources and help make the construction sector more sustainable.

Integration with Existing Waste Management Systems

Adding gypsum board recycling to your waste management needs careful planning. The Drycake Twister is a game-changer for recycling gypsum board. But, its success depends on several key factors.

Compatibility Considerations

When adding the Drycake Twister, think about space and power. The machine's size and energy use must fit your current setup. It's vital to make sure the Twister works well with other recycling gear without causing problems.

| Factor | Consideration |

|---|---|

| Space | Minimum area required for Twister installation |

| Power | Electrical requirements and capacity |

| Integration | Compatibility with existing machinery |

| Waste Volume | Processing capacity alignment |

Implementation Strategies

Start with a step-by-step plan to add the Twister to your system. First, check how your current recycling works and where the Twister fits best. Training your team on the new recycling method is key for smooth running.

Remember, recycling gypsum board is not just smart; it's the law. The Environmental Agency says you must separate plasterboard from other waste to stop harmful gases. Using the Drycake Twister helps you manage waste better and follow the rules.

Success Stories: Sustainable Gypsum Board Recovery

The gypsum board recycling industry is growing fast. A big example is in Austria, where PORR, Saint-Gobain, and Saubermacher teamed up. They've created a closed-loop recycling model that shows how to reuse gypsum board in a big way.

In Austria, a recycling plant can handle 60,000 tons a year. It cost €7 million to set up, showing the industry's big investment in new tech. This plant is a big step forward, using up to 40% recycled gypsum in new plasterboard.

PORR is the biggest recycler in Austria's building sector. They deal with 2 million tons of waste every year. Their focus on using gypsum board again is leading to new, green ways of working in the industry.

“The gypsum-to-gypsum recycling plant in Austria is a prime example of how collaboration and investment in advanced technologies can transform waste management practices in the construction industry.”

The European Commission's Green Deal is pushing the industry to change. It wants all coal-fired power plants closed by 2035. This means the industry must find new ways to recycle and reuse gypsum, helping to create a more circular economy.

Return on Investment: Economic Benefits of Gypsum Recycling

The gypsum board recycling industry brings big economic wins for construction projects. With plasterboard waste at 12% during installation, recycling can save a lot of money.

Cost Analysis and Savings

Companies can cut raw material costs by recycling gypsum board. A study showed redesigning plasterboard usage cut raw material use by 50%. Also, ordering plasterboard to size can reduce waste from 12% to 3.5%, saving money right away.

Long-term Financial Benefits

Recycling gypsum board offers more than just quick savings. The global gypsum market is expected to grow 4.5% from 2023 to 2030. Investing in recycling tech helps businesses thrive long-term. Recycling can also cut energy use by up to 25%, saving a lot of money over time.

| Aspect | Without Recycling | With Recycling |

|---|---|---|

| Wastage Rate | 12% | 3.5% |

| Energy Consumption | 100% | 75% |

| Raw Material Usage | 100% | 50% |

As the green building materials market is set to hit $400 billion by 2028, adopting gypsum recycling is smart. It not only saves money but also fits with industry trends. This could open up new revenue streams and boost competitiveness in the changing construction world.

Conclusion: Embracing Sustainable Gypsum Board Management for a Greener Future

The construction industry is moving towards greener ways. Solutions, like the Drycake Twister to separate contaminant materials from skip loads of plasterboard waste, are making a big difference. They help reduce the cost of processing this waste and save resources.

Recycling gypsum can save a lot of energy and materials. For example, recycling one tonne of gypsum saves 28 kWh of energy and 4 pounds of aluminium. This shows how big the environmental benefits are.

Sustainable practices are making a big impact. Recycling gypsum waste can cut down landfill emissions by up to 90%. This also reduces the need for new resources by up to 30%.

Using Carbon Capture and Utilisation technology can cut greenhouse gas emissions from gypsum production by 20-30%. This is a big step towards a cleaner future.

Adopting sustainable gypsum board management is key for a greener future. Over 60% of gypsum manufacturers are now focusing on sustainability. They're working to reduce their environmental impact.

By using technologies like the Drycake Twister and recycling more, we can make a big difference. This not only helps the environment but also saves money. For more info on sustainable gypsum board disposal and reuse, visit Drycake Twister or call +1-843-TWISTER.

FAQ

What is gypsum board recycling?

Why is gypsum board recycling important?

What is the Drycake Twister?

How does the Drycake Twister work?

What are the environmental benefits of using the Drycake Twister?

Are there economic benefits to gypsum board recycling?

How does the Drycake Twister comply with UK regulations?

Can the Drycake Twister be integrated into existing waste management systems?

How does gypsum board recycling contribute to a circular economy?

What is the return on investment for implementing the Drycake Twister?

Source Links

- PROTESIS REMOVIBLE, RENFERT – https://www.slideshare.net/slideshow/renfort-catlogo/49855095

- 34 Types of Construction Waste to Include in your SWMP – https://landfill-site.com/34-types-of-construction-waste/

- Microsoft Word – Victor Giannini Thesis.docx – https://repo.library.stonybrook.edu/xmlui/bitstream/handle/11401/71522/Giannini_grad.sunysb_0771M_11174.pdf?sequence=5

- Gypsum Recycling – https://feeco.com/gypsum-recycling/

- Gypsum recycling – https://en.wikipedia.org/wiki/Gypsum_recycling

- Recycling – Gypsum Association – https://gypsum.org/recycling-gypsum-wallboard/

- Emerging Trends in Gypsum Board Plant Lines: Addressing Evolving User Demands and Future Industry Challenges – https://insights.made-in-china.com/Emerging-Trends-in-Gypsum-Board-Plant-Lines-Addressing-Evolving-User-Demands-and-Future-Industry-Challenges_QfaGcACYFJiq.html

- Environmental Evaluation of Gypsum Plasterboard Recycling – https://www.mdpi.com/2075-163X/11/2/101

- Microsoft Word – 1.done.doc – https://www.irbnet.de/daten/iconda/CIB877.pdf

- Vakbeurs Recycling 2025 – Recycling Vakbeurs – https://www.recyclingvakbeurs.nl/en/edition/vakbeurs-recycling-2025/

- Full text of “Chemical & Metallurgical Engineering 1928-12: Vol 35 Iss 12” – https://archive.org/stream/sim_chemical-engineering_1928-12_35_12/sim_chemical-engineering_1928-12_35_12_djvu.txt

- Recycling – Plasterboard Sustainability Partnership – https://plasterboardpartnership.org/recycling/

- Bagging It Safely: Proper Disposal Methods for Plasterboard – https://www.kentskips.com/blog/bag-it-up-how-to-dispose-of-plasterboard-safely/

- Environmental Benefits of Gypsum Board Construction – https://specializeddrywallojinc.com/the-environmental-benefits-of-gypsum-board-construction/

- How to Recycle Plasterboard: Eco-Conscious Solutions – https://it-recycle.uk/how-to-recycle-plasterboard-eco-conscious-solutions/

- Plasterboard Recycling & Removal – https://www.hippowaste.co.uk/blog/plasterboard-recycling-removal/

- Solving Plasterboard Problems and Efficient Waste Removal – https://wasteonline.uk/blog/solving-plasterboard-problems-and-efficient-waste-removal/

- Dispose of waste to landfill – https://www.gov.uk/guidance/dispose-of-waste-to-landfill

- BNDG10 – http://www.eurogypsum.org/wp-content/uploads/2015/05/N0615.pdf

- How to dispose of plasterboard – Rabbit Skip Hire – https://www.rabbitskips.co.uk/news/how-to-dispose-of-plasterboard/

- Optimization of Double-Shaft Shredder for Gypsum Board Processing – https://www.aishred.com/release/optimization-of-double-shaft-shredder-for-gypsum-board-processing.html

- PDF – http://www.eurogypsum.org/wp-content/uploads/2015/04/Waste2007.pdf

- Recycling Plasterboard: The Ultimate Guide – https://landfill-site.com/recycling-plasterboard/

- Gypsum Board Recycling Machine – Professional Solutions – https://jiantaimachine.com/gypsum-board-recycling-machine-professional-solutions/

- Reliability of Reusing Gypsum Flat Board Grinded Waste as a Conventional Plaster Replacement for Buildings – https://www.mdpi.com/2071-1050/16/18/7889

- Gypsum Recycling: An Environmental and Industrial Solution – GreyB – https://www.greyb.com/blog/sustainable-gypsum-board-recycling/

- Unlocking Hidden Value: Recycling Paper Waste from Gypsum Boards – https://www.linkedin.com/pulse/unlocking-hidden-value-recycling-paper-waste-from-gypsum-cboxe

- Starting signal for the first gypsum-to-plaster recycling plant in Austria – recovery Magazine – Recycling Technology Worldwide – https://www.recovery-worldwide.com/en/artikel/starting-signal-for-the-first-gypsum-to-plaster-recycling-plant-in-austria-4038989.html

- BNDG9 – http://www.eurogypsum.org/wp-content/uploads/2015/05/N0712.pdf

- Gypsum Market Size And Projection – https://www.marketresearchintellect.com/blog/sustainable-construction-gains-momentum-with-innovations-in-the-gypsum-market/

- Eco-Friendly Gypsum Production Line Initiatives for a Greener Future – http://en.ncmachinery.cn/news_detail/1868108717857656832.html

- Sustainable Dentistry: A Comprehensive Review of the Recycling Techniques for Gypsum Products in Prosthodontics – https://pmc.ncbi.nlm.nih.gov/articles/PMC11007482/

- Gyrock to Gypsum: Plasterboard Recycling in Australia – https://wasteinitiatives.com.au/news/plasterboard-recycling/