Sustainable waste management is the holy grail of the concept of the circular economy. Unless the waste industry can achieve that on a global scale, a truly sustainable world is unachievable.

It's crucial to comprehend how the effectiveness of an MRF or ERF in achieving the clean extraction of plastics and bioplastics from the OFMSW has a significant impact on achieving sustainable waste management.

Dirty plastics and bioplastics in OFMSW are a serious problem that must be solved for efficient energy recovery and a vital step toward fully sustainable waste management.

Our intent is to show how negative the impact is on energy recovery efficiency if significant organic material remains in the reject stream instead of within the organic output (pulp) where it should be.

To do that, we will first focus in this article on the specific processing of the OFMSW (Organic Fraction of Municipal Solid Waste) on its journey through any mixed MSW recycling or material reclamation (or recovery) facility.

Stay with us while we start by explaining how the separation of the OFMSW fraction is achieved by detailing the journey of the organic matter through the various stages of mixed MSW residual waste processing.

Please keep reading! This is a fairly complex subject, and to appreciate this subject does require an appreciation of the following:

Separating OFMSW in MRFs and ERFs: A Detailed Journey

The separation of the organic fraction of municipal solid waste (OFMSW) in MRFs and ERFs is a meticulously designed process. Understanding this process is key to appreciating how sustainable waste management practices are implemented.

Let's follow the journey of OFMSW from its arrival to its segregation.

Initial Reception and Opening

Mixed residual MSW arrives at the facility via refuse collection vehicles (RCVs) and is typically unloaded into a large hopper. This initial stage is critical, as it marks the beginning of the sorting process. The waste, often still contained in bags, is then fed onto a conveyor system, where it undergoes initial processing.

1. Bag Opening and Initial Sorting

The first step involves opening the waste bags to allow access to the mixed contents. This is typically achieved using bag openers or ripping claws, which tear the bags to release the waste material for subsequent sorting.

2. Screening Process

After the bags are opened, the waste is subjected to screening processes. Here, different types of screens are employed:

- Trommel Screens: Rotating drum screens that separate waste based on size. Smaller organic materials pass through the holes, while larger items are retained.

- Alternative Screening Types: In addition to trommels, other screening methods like disc screens, star screens, and shaking tables are also used. These screens effectively separate materials based on size and shape, enhancing the segregation of organic matter.

Use of Alternative Screening, including Shaking Tables for OFMSW Separation

An alternative to screening is the use of a variety of patented machinery, which we shall generically call “shaking tables.” These tables utilize vibration, item geometry, and gravity to segregate waste.

- Shaking Tables: These tables agitate the waste, causing lighter, organic materials to move to the top while heavier, inorganic materials settle at the bottom. This separation is based on factors such as size, shape, and density and is particularly effective in segregating smaller organics from heavier, inorganic particles.

Path of the Organic Fraction

Once the organic material is separated through screening or shaking tables, it embarks on a different path compared to the other materials:

- The smaller fraction, rich in organic content, is directed towards further processing. This may include additional sorting, manual picking to remove contaminants, and, for optimum sustainability, preparation for biological treatment like anaerobic digestion.

- The small, heavy fraction of stone, grit, etc. drops out and may be further processed for use in certain construction uses.

- In contrast, the larger, non-organic materials (often referred to as the “oversized fraction”) and the light 2D materials (like paper and plastics) follow a separate processing route for recycling or recovery.

In this article, from now on, we will solely discuss the organic fraction known as the “OFMSW.”

Ensuring Efficiency and Sustainability

The efficient separation of the OFMSW is crucial for sustainable waste management. By efficiently segregating organic matter from mixed residual waste in MRFs and ERFs with low organic contamination levels in the “rejects” to below 5%, these facilities can be said to provide sustainable waste management by:

- contributing to the maximum reduction of landfill usage,

- promotion of the most appropriate level of recycling in compliance with the waste hierarchy, and

- maximizing the generation of renewable energy via anaerobic digestion.

The choice and combination of screening and separation technologies are therefore vital to the success of these facilities in managing waste responsibly and sustainably.

This detailed explanation so far is designed to help readers understand the specific processes involved in the pretreatment and separation of OFMSW in MRFs and ERFs and where OFMSW fits within that context.

Next, we will explain the importance of the OFMSW separation step in the journey of organic matter through the waste facility when, as is increasingly normal, the accepted BAT (Best Available Technology) for organic waste is energy recovery by using the anaerobic digestion process.

The Importance of Optimizing OFMSW Quality for Sustainable Waste Management: A Crucial Factor that Influences the Income from Energy Extraction from MSW

Understanding the intricacies of achieving the best (most sustainable) output of the organic fraction of municipal solid waste (OFMSW) is pivotal in our journey toward sustainable waste management.

The takeaway fact that we hope you will remember is that the best output means not only that the OFMSW is free from inert contaminants, but that as little as possible is lost as organic material and water stuck to, or entrained with, the reject stream

So, to recap for a moment: OFMSW primarily consists of biodegradable waste such as food scraps, garden waste, and other naturally organic materials found within municipal solid waste (MSW). Its management via anaerobic digestion as a form of “energy extraction” is accepted to be the most sustainable and plays a critical role in our efforts to create a more sustainable “circular” and eco-friendly waste-processing system.

The separation of organic matter from other components in MSW is not just an environmental imperative but also an economic one.

Lost Income from Organics and Water Lost to the Non-organic “Reject” Stream

When organic material is efficiently extracted from MSW, it becomes a valuable resource for bioenergy production, particularly through the anaerobic digestion processes. This process involves breaking down organic matter in the absence of oxygen, leading to the production of biogas, a renewable source of energy.

However, the efficiency of this process heavily depends on:

- The purity of the organic fraction

- The ability of the processing equipment to separate the OFMSW for its use as a biogas plant feedstock without a high percentage, quite often as high as 20%, being carried over into the “reject” stream.

Let us be clear: Any organic material that inadvertently enters the “rejects” stream during the separation process, at the point where the OFMSW is finally processed to make it suitable for feeding an anaerobic digester, is not just a loss of potential energy; it represents a significant economic setback.

This lost organic matter could have been converted into biogas, thereby contributing to profitable bioenergy production. Instead, its misplacement leads to the dual economic burden of:

- lost energy potential and

- the additional costs incurred for the responsible disposal of the “reject” stream, which is frequently of too low a calorific value to be classified as anything other than waste, requiring its disposal to landfill or incineration and incurring either landfill tax or the high cost of incineration as a waste.

The High Cost of Dirty Rejects

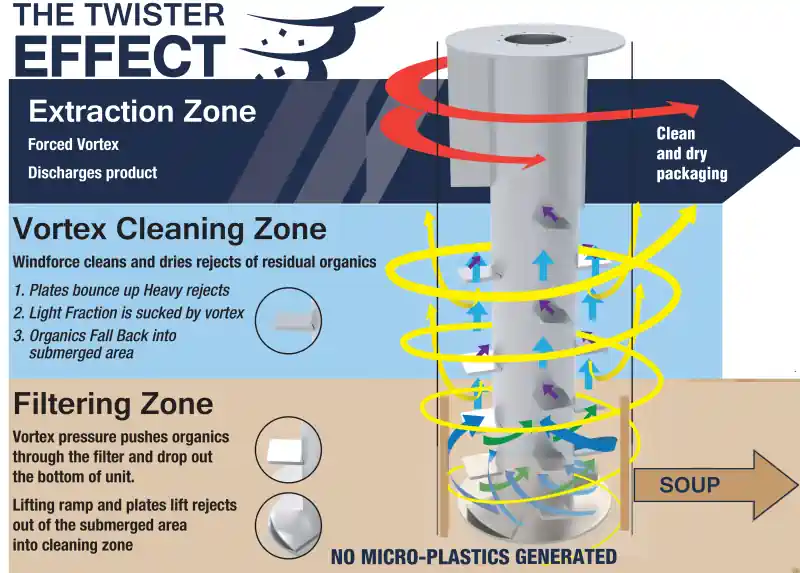

The following cost assessment is an illustration of the financial loss from an industry-standard “particle size reduction style separator” when compared with the far cleaner rejects from the current generation of purpose-designed depackagers and separators, like the Twister™:

A modern machine will typically achieve 95% organics separation, whereas older “shredding and milling” based designs may do no better than 20% separation.

So, if say 10% by weight of organic matter is lost from the pulp output fed to the anaerobic digester

- 10% of the calorific content of the organic waste fails to be available for biogas production and 10% of the earnings from biogas are lost

- A damp reject output with organic content is not likely to be accepted as a fuel for energy recovery, meaning that it will have to be sent to landfill, or incinerated as a “waste material” incurring a cost. In the UK, that's a charge of over £100/tonne.

The result of dirty rejects is a double hit on profitability

How to Buy an Efficient Separator

Older designs of equipment known as depackagers and separators, which are unfortunately still used for this purpose, are designed for particle size reduction. The milling and shredding are prone to the production of a reject stream that is a mess of dirty wet plastic and small metal and plastic shards that make its sustainable reuse in line with the principles of the “waste hierarchy” impossible.

The hierarchy prioritizes waste prevention, reuse, recycling, and energy recovery, with disposal coming last.

Therefore, the selection of machinery and technology for the separation of the cleanest OFMSW is of utmost importance, both for reasons of economic energy recovery and sustainability.

The goal is to:

- maximise the amount of valuable organic material that is processed into organic pulp for anaerobic digestion.

- output clean rejects that, after further sorting alone, become valuable recycled products.

Machines and processes that do this not only enhance the efficiency of biogas production but also provide an important contribution to the economic viability and environmental sustainability of these recycling systems.

This makes the choice of technology a critical factor in the successful implementation of sustainable OFMSW treatment strategies.

Some of the best separation of OFMSW before feeding a digester tank is achieved by the use of air vortex separation in combination with other physical separation techniques, as employed in the innovative patented Twister™ Separator by Drycake.

More details are available at: https://www.twisterseparator.com

Now let us take a look at the vexed question of:

Understanding the Impact of Plastics and Bioplastics on OFMSW Treatment

The treatment of the organic fraction of municipal solid waste (OFMSW) is crucial for sustainable waste management.

However, the presence of micro- and nano-plastics, as well as a rising incidence of bioplastics (so-called “compostable” bags and packaging), in OFMSW poses significant challenges. This detailed review explores the effects of these materials in two main OFMSW treatment operations: anaerobic digestion and aerobic composting.

Anaerobic Digestion: Challenges and Effects

Key Parameters in Anaerobic Digestion

- Dry matter content of the substrate (dry, wet, and semi-dry digestion)

- Average temperature and fermentation process (psychrophilic, mesophilic, and thermophilic processes)

- Loading system for substrate (continuous or batch)

- Number of reactors (one-stage or multi-stage technologies)

- Type of reactors (vertical, horizontal, mixing technology)

Comparison of Effects of Plastics and Bioplastics Contamination

Both plastics and bioplastics significantly impact the efficiency and quality of all anaerobic digestion processes.

The presence of bioplastics is, at best, unhelpful. If bioplastic is not fully broken down and digested in the anaerobic digester, the bioplastic content will (1.) reduce the carbon conversion rate, but on other listed parameters (2. to 5.), it will not significantly have an impact over and above that of any type of plastic still present at the feed inlet.

These effects include:

| Impact | Plastics Contamination | Bioplastics Contamination |

|---|---|---|

| Reduction in biogas yields | The increased surface area of plastics leads to greater reduction as the plastic content rises. | Similar decrease in biogas yields. |

| Operational Challenges | Accumulation, stretching processes, clogging pumps, wrapping around stirrers. | Similar operational challenges as with conventional plastics a re assumed due to the absence of studies showing the rate of decomposition in the digester. |

| Impact on Microbial Communities | The release of harmful substances is likely, to lead to unproductive modification of microbial communities. | Far reduced risk of modification of microbial communities involved. |

Now we take a look at the fate of plastics during the composting process, and here the point to remember is that the fibrous residue from anaerobic digestion is normally subjected to composting as the final step before that material is applied to land as a fertilizer, and soil improver.

Any non-digestable plastics in the digester feed material will eventually appear in the digestate and all but the nano-plastic, much of which will float into the liquid digestate (fertiliser) will be present in the compost.

Bioplastics may or may not, in the years to come, prove to provide any life-cycle sustainability benefits. Most often, the current MRF and ERF equipment simply has no means of handling them any differently from non-renewable plastic. Thus, they have no benefits in connection with waste management sustainability, which brings us to the fate of plastic contamination during composting:

Composting: Addressing the Presence of Plastics

Composting Parameters

- Feedstock properties (moisture content, C/N ratio, density)

- pH value.

- Temperature.

- Aeration/oxygen supply.

- CO2 production and odour generation.

Challenges Posed by Plastics and Bioplastics

Plastics and bioplastics in compost, at above the criteria for acceptance under PAS110, lower the quality of compost and require more processing steps. For example, the final screening step is needed to reduce the size of the plastics so that they do not look bad, but this increases the amount of microplastics in the compost, making it even less environmentally friendly.

Note: WRAP (UK) created PAS110 to help build a market for the use of anaerobic digestate as a renewable fertiliser. Important points.: It controls the classes of input materials, the management system for the anaerobic digestion process, and related technologies.

Although the digestate compost from

Therefore, the following compromise prevents sustainable waste management when plastic is carried over into the biogas digester:

- low compost quality due to the presence of microplastics (MPs) and micro-bioplastics (MBPs).

- There is a need for sieving, manual sorting, or magnetic separation before or after composting.

- Modification of microbial communities involved in the composting process.

Conclusion

The treatment of OFMSW is a critical component of sustainable waste management, yet the presence of plastics and bioplastics poses significant challenges. Understanding these impacts is crucial for developing effective strategies to manage and mitigate these issues in our ongoing efforts towards environmental sustainability.

FAQs About OFMSW Treatment and Plastic Pollution

1. What are the main challenges of treating OFMSW with plastics present?

The presence of plastics and bioplastics in OFMSW can reduce biogas yields, complicate operational processes, and alter microbial communities.

2. How do plastics affect compost quality?

Plastics lower the quality of compost and require additional processing steps like sieving and sorting.

3. Can bioplastics be treated the same as conventional plastics in waste management?

While bioplastics present similar challenges as conventional plastics, they may require different treatment processes due to their unique properties.

Key Reference:

This article is based upon the published paper: “The treatment of the organic fraction of municipal solid waste (OFMSW) as a possible source of micro and nano-plastics and bioplastics in agroecosystems: A Review“, by Francesca Bandini, Eren Taskin, Gabriele Bellotti, Filippo Vaccari, Chiara Misci, Maria Chiara Guerrieri, Bandini et al. Chem. Biol. Technol. Agric. (2022) 9:4

https://doi.org/10.1186/s40538-021-00269-w , Pier Sandro Cocconcelli and Edoardo Puglisi