What is Thermal Waste-to-Energy?

Thermal waste-to-energy is a process that converts non-recyclable waste materials into usable heat, electricity, or fuel through the combustion of these organic materials. WtE facilities capture the heat energy released during combustion to generate electricity or provide district heating.

This technology serves dual purposes: it reduces the volume of waste sent to landfills by up to 90% while producing renewable energy that can power thousands of homes and businesses. Modern WtE plants employ sophisticated emissions control systems to minimise environmental impact.

“Waste-to-energy (MSW) in depth – U.S …” from www.eia.gov and used with no modifications

“Municipal Solid Waste | Wastes | US EPA” from archive.epa.gov and used with no modifications.

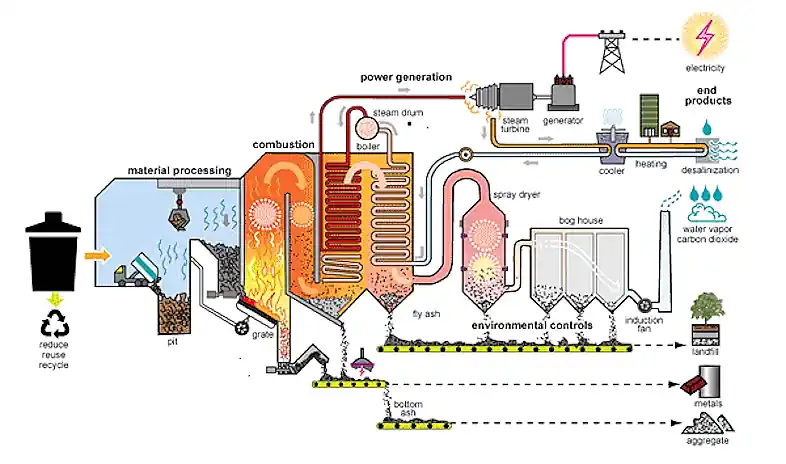

Waste Collection

The process begins with the collection of municipal solid waste (MSW) from homes and businesses. Upon arrival at the WtE facility, waste undergoes sorting to remove recyclable materials and non-combustibles like metals and glass. The remaining waste is then shredded to create a more uniform fuel.

Waste is collected from each house.

“Municipal solid waste (MSW) collection – Bollegraaf” from www.bollegraaf.com and used with no modifications.

Waste Preparation & Feeding

Municipal solid waste undergoes initial processing, including sorting, shredding, and moisture reduction, before being fed into the combustion system.

On arrival at the incineration facility, the waste is sorted using a variety of processes. One of these is manual waste picking to remove the recyclable materials from a moving conveyor, as shown below:

Waste sorting and preparation for the waste-to-energy process

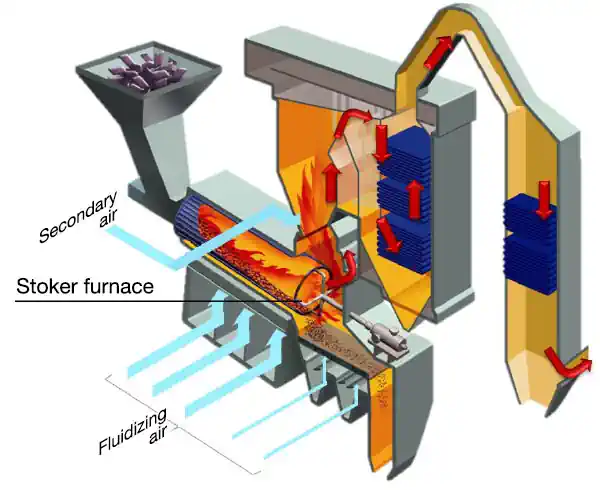

Combustion & Steam Generation

The prepared waste is fed into a combustion chamber where it burns at temperatures exceeding 850°C (1,560°F). This high temperature is crucial for complete combustion and the breakdown of complex organic compounds. The heat generated converts water in boiler tubes into high-pressure steam.

“garbage incinerators” from www.rsnewrefractory.com and used with no modifications.

Electricity Generation & Distribution

The high-pressure steam drives turbines connected to generators, producing electricity. A typical WtE plant can generate 500-600 kWh of electricity per ton of waste processed, though the exact amount varies depending on the calorific value and moisture content of the waste, as well as the efficiency of the waste-to-energy plant. Some plants may produce less (e.g., 350–400 kWh/ton) or more (e.g., up to 990 kWh/ton), depending on these factors.

This electricity is then fed into the local grid to power homes and businesses, providing a reliable baseload energy source.

Emissions Control & Ash Management

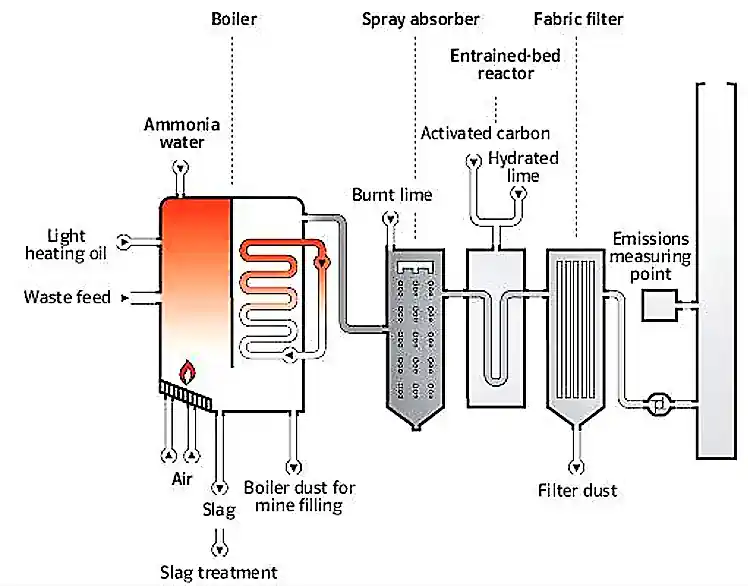

Modern WtE facilities employ sophisticated emissions control systems to meet strict environmental regulations. These include:

Air Pollution Control

- Selective catalytic reduction (SCR) systems to remove nitrogen oxides

- Fabric filters to capture particulate matter

- Activated carbon injection to absorb heavy metals and dioxins

- Scrubbers to neutralize acid gases like sulfur dioxide

“Incineration (Large-scale) AIR POLLUTION CONTROL | SSWM …” from sswm.info and used with no modifications.

Ash Processing

- Bottom ash (15-25% of the original waste volume) can be used in construction materials

- Metals recovered from ash are recycled

- Fly ash is carefully managed, as it may contain concentrated pollutants

- Advanced treatment can render ash suitable for beneficial reuse, and this can mean zero waste goes to landfill

Sustainability Benefits of Waste-to-Energy

Environmental Advantages

- Reduces waste volume by up to 90%, significantly extending landfill lifespans

- Prevents methane emissions that would occur from waste decomposition in landfills

- Recovers metals for recycling that might otherwise be landfilled

- Generates renewable baseload electricity, reducing reliance on fossil fuels

- Requires less land than equivalent landfill space (1 acre vs. 10+ acres for the same waste)

Challenges to Consider

- High initial capital costs for facility construction

- Public concerns about emissions and air quality impacts

- Requires careful monitoring and control of combustion conditions

- May compete with recycling efforts if not properly integrated

- Ash management requires appropriate handling and disposal protocols

Did you know? One ton of municipal solid waste processed in a WtE facility can generate enough electricity to power an average home for about one month.

- your family desires.

“Greenhouse Gas Emission Calculations …” from www.mdpi.com and used with no modifications.

Comparing WtE to Alternative Waste Management Methods

| Method | Energy Recovery | Volume Reduction | Greenhouse Gas Impact | Land Requirements | Capital Costs |

| Thermal WtE (Mass Burn) | High (500-600 kWh/ton) | 90% | Medium (controlled CO?) | Low | High |

| Landfill with Gas Recovery | Low (100-200 kWh/ton) | None | High (methane leakage) | Very High | Medium |

| Anaerobic Digestion | Medium (biogas) | 50-70% | Low | Medium | Medium |

| Gasification | High (syngas) | 85-95% | Low-Medium | Low | Very High |

While each waste management approach has its merits, thermal waste-to-energy offers a balanced solution for non-recyclable waste streams. It provides significant volume reduction while recovering energy that would otherwise be lost. Modern facilities with advanced emissions controls can achieve environmental performance that complements recycling and composting programs.

Real-World Success Stories

Sweden's WtE Leadership

Sweden has become a global leader in waste-to-energy implementation, with approximately 50% of household waste processed in WtE facilities. The country has been so successful that it now imports waste from neighboring countries to fuel its plants. District heating networks distribute the thermal energy to homes and businesses, achieving over 90% energy efficiency.

Singapore's TuasOne Plant

Singapore's TuasOne waste-to-energy plant processes 3,600 tonnes of waste daily while generating enough electricity to power over 1,000 homes. The island nation has limited land for landfills, making WtE an essential component of their waste management strategy. The facility reduces waste volume by 90% and recovers ferrous and non-ferrous metals for recycling.

Implementing Waste-to-Energy Systems

Key Considerations for WtE Projects

Technical Factors

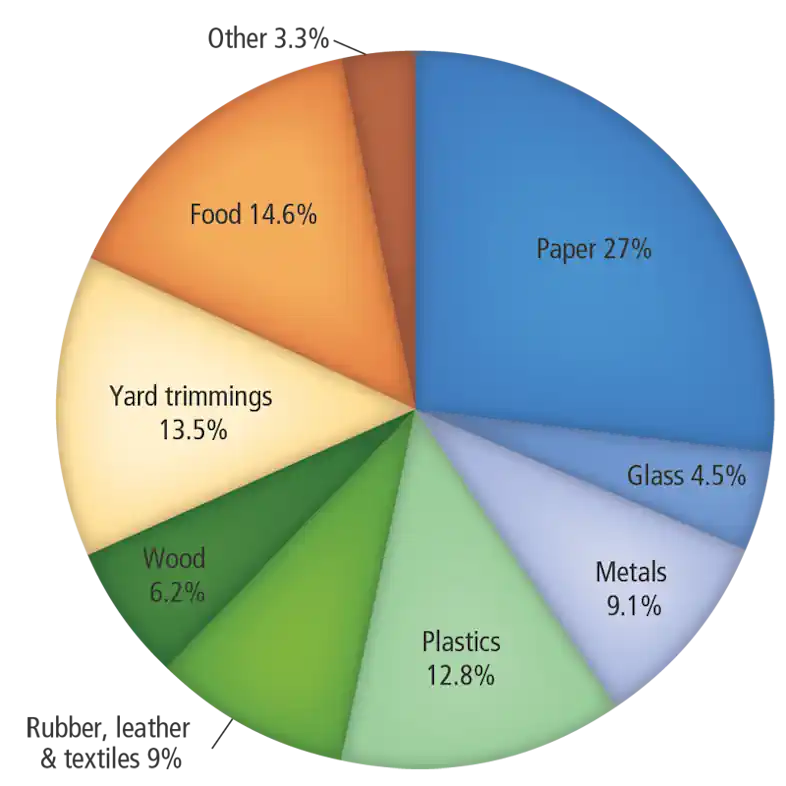

- Waste composition analysis to determine energy content

- Facility sizing based on waste generation rates

- Selection of appropriate combustion technology

- Grid connection requirements and capacity

- Emissions control system design

Regulatory Requirements

- Environmental impact assessment

- Air quality permits and emissions monitoring

- Waste management licensing

- Energy generation permits

- Ash management and disposal regulations

Economic Considerations

- Capital investment requirements (£200-300 million for mid-sized plant)

- Operational costs and maintenance planning

- Revenue streams (tipping fees, electricity sales, heat sales)

- Potential renewable energy incentives

- Long-term waste supply contracts

Planning Timeline: Developing a waste-to-energy facility typically requires 3-5 years from initial planning to operational status, including permitting, design, construction, and commissioning phases.

Future Trends in Waste-to-Energy Technology

Advanced Conversion Technologies

Next-generation WtE systems are moving beyond traditional combustion to more sophisticated approaches:

- Plasma gasification, which uses extreme temperatures to break down waste into syngas

- Pyrolysis processes that thermally decompose waste in oxygen-free environments

- Chemical recycling of plastics to recover fuel or chemical feedstocks

- Integrated systems combining multiple conversion technologies

Enhanced Efficiency & Integration

Modern facilities are achieving greater overall efficiency through:

- Combined heat and power (CHP) systems that utilise both electricity and heat

- Integration with district heating networks for community energy supply

- Carbon capture technologies to reduce greenhouse gas emissions

- Smart grid integration for optimised electricity distribution

A Bridge to Nowhere? Incineration is a Transition Technology and Will be Phased Out

While waste-to-energy incineration might appear to be a clean solution to our mounting waste crisis, the reality is more sobering. Despite its green credentials in diverting waste from landfill, incineration represents at best a transitional technology on our path toward a truly circular economy—and at worst, a costly detour that could derail our climate ambitions.

The Carbon Problem: Incineration is Not as Green as It Seems

The Fossil Carbon Reality

The fundamental issue lies in the carbon footprint. Burning waste produces net carbon emissions: in 2019, incineration produced 5 megatonnes of CO2-equivalent, representing around a quarter of emissions from UK waste. Unlike truly renewable energy sources, the CO2 released from burning municipal waste isn't part of a recent carbon cycle. Much of what we incinerate—plastics, synthetic materials, and processed goods—represents fossilised carbon that has been locked away for millions of years. When we burn these materials, we're effectively releasing ancient carbon back into the atmosphere, contributing to the very problem we're trying to solve.

The Net Zero Conflict

The scale of this challenge becomes stark when considered against the UK's net zero commitments. For those that have studied the sector, the conclusion is clear: the rising incineration rate is a cause for alarm, locking the UK into a polluting future when it should be doing all it can to reach the target of net zero emissions by 2050. The timing couldn't be more critical. Currently, about 3.1 per cent of the UK's energy comes from waste incinerators, and with projections suggest that by 2035, energy from waste plants will be capable of dealing with 18.8 million tonnes of residual waste, we risk creating infrastructure that directly conflicts with our climate goals.

Undermining the Circular Economy

Economic Opportunity Lost

Perhaps more troubling is how incineration actively undermines the circular economy we desperately need to build. The circular economy isn't just an environmental ideal—it's an economic necessity in a world of finite resources. 10,000 tonnes of waste can create up to 296 jobs in repair and reuse, compared to just 1 job in incineration, 6 jobs in landfill or 36 jobs in recycling. When we choose to burn materials rather than design systems to keep them in productive use, we're not just losing valuable raw materials—we're forgoing significant economic opportunities.

The Resource Destruction Problem

The statistics paint a concerning picture of our current trajectory. Almost half of all waste (49%) collected by local authorities in 2022/23 was incinerated, with just 40% recycled. This represents a fundamental misallocation of resources. Once materials have been reduced to ash and emissions, they're gone forever. The aluminium that could have been recycled indefinitely, the plastics that could have been reprocessed, the organic matter that could have enriched soil—all transformed into carbon dioxide and clinker.

Policy Recognition and Future Constraints

The government appears to recognise these limitations. Recent policy shifts suggest an acknowledgement that our current incineration trajectory is unsustainable, with stricter standards being introduced for new builds and recognition that the nation is reaching a point where national waste treatment capacity is sufficient to manage the total amount of non-recyclable waste households produce. This signals a potential ceiling on future incineration capacity, but raises questions about what happens to existing infrastructure as we move toward 2050.

The Path Forward: Planning for Transition

The path forward requires honest recognition that incineration, while perhaps necessary in the short term for managing residual waste, cannot be a long-term solution. Concerns around incineration have focused on increasing carbon emissions, reducing air quality, burning materials that could otherwise be recycled, and preventing a shift to a more circular economy. As we design our waste management systems for the next thirty years, we must resist the temptation to build infrastructure that locks us into a linear, burn-and-forget mentality.

Instead, incineration must be treated as exactly what it is—a bridge technology that buys us time while we build the systems, policies, and behaviours needed for true circularity. This means planning not just for the construction of incineration plants, but for their eventual decommissioning as prevention, reuse, and recycling systems mature. Only by acknowledging these limitations can we ensure that today's pragmatic choices don't become tomorrow's stranded assets in our race toward net zero.

Key Takeaways

- Incineration has been great, but it is now reaching the time when it has served its purpose: Waste-to-energy incineration has been a great interim solution for disposing of waste and diverting it from landfill, but it's now time to think seriously about phasing it out as we move toward a truly circular economy.

- Carbon emissions concerns: Burning waste produces net carbon emissions: in 2019, incineration produced 5 megatonnes of CO2-equivalent, representing around a quarter of emissions from UK waste

- Conflict with net zero targets: The rising incineration rate is a cause for alarm, locking the UK into a polluting future when it should be doing all it can to reach the target of net zero emissions by 2050

- Circular economy conflicts: Concerns around incineration have focused on increasing carbon emissions, reducing air quality, burning materials that could otherwise be recycled, and preventing a shift to a more circular economy

- Current UK capacity data: Current projections suggest that by 2035, energy from waste plants will be capable of dealing with 18.8 million tonnes of residual waste, with about 3.1 per cent of the UK's energy coming from waste incinerators

- Economic comparison: 10,000 tonnes of waste can create up to 296 jobs in repair and reuse, compared to 1 job in incineration, 6 jobs in landfill or 36 jobs in recycling

Conclusion: The Role of WtE in a Circular Economy

The Current Value Proposition

Generating electricity from waste through thermal waste-to-energy systems represents an important component in sustainable waste management strategies. While recycling and waste reduction remain priorities, WtE offers a practical solution for non-recyclable waste streams that would otherwise end up in landfills.

Today's Technical Capabilities

Modern WtE facilities with advanced emissions controls can provide reliable renewable energy while significantly reducing waste volumes. As part of an integrated waste management approach, these systems help communities move toward circular economy principles where resources are kept in use for as long as possible.

The Innovation Path Forward

The future of waste-to-energy lies in continued technological innovation, improved efficiency, and integration with other renewable energy sources. By balancing environmental protection with energy recovery, WtE systems will continue to play a valuable role in our transition to more sustainable waste and energy systems.

But… And It's a BIG “But”!

The Long-Term Reality Check

The harsh reality is that incineration cannot be our long-term answer to waste management if we're serious about achieving net zero by 2050 and building a truly circular economy. While it may serve as a necessary stepping stone in managing today's residual waste, the 5 megatonnes of CO2 it produces annually, its destruction of valuable raw materials, and its capacity to create just one job per 10,000 tonnes compared to 296 in reuse makes incineration a poor investment for the future.

The Transition Imperative

As the UK approaches sufficient national waste treatment capacity and recognises the unsustainable trajectory of current incineration rates, the focus must shift decisively toward prevention, reuse, and recycling—systems that keep materials in productive use rather than converting them to emissions and ash.

The Ultimate Question

The question isn't whether we can afford to transition away from incineration, but whether we can afford not to, as every tonne we burn today represents a missed opportunity for tomorrow's circular economy and a step away from our climate commitments.

Generating Electricity from Waste – Frequently Asked Questions

How much electricity can be generated from one ton of waste?

A modern waste-to-energy facility can typically generate between 500-600 kilowatt-hours (kWh) of electricity per ton of municipal solid waste processed. This is enough to power an average UK home for approximately one month. The exact energy output depends on the waste composition, with higher calorific materials like plastics producing more energy than food waste.

Are waste-to-energy emissions harmful to the environment?

Modern waste-to-energy facilities employ sophisticated emissions control systems that remove pollutants before gases are released. These systems typically include scrubbers, fabric filters, selective catalytic reduction, and activated carbon injection to control acid gases, particulates, nitrogen oxides, and heavy metals. When properly operated, WtE plants can meet strict emissions standards that are comparable to or better than those of natural gas power plants.

Does waste-to-energy compete with recycling efforts?

When implemented as part of an integrated waste management strategy, waste-to-energy complements rather than competes with recycling. Countries with the highest recycling rates, such as Germany, Austria, and the Netherlands, also have significant WtE capacity. The ideal approach follows the waste hierarchy: reduce, reuse, recycle, recover (WtE), and finally dispose (landfill). WtE is positioned to handle non-recyclable waste streams after recycling efforts have been maximised.

What happens to the ash produced by waste-to-energy facilities?

Waste-to-energy facilities produce two types of ash: bottom ash (80-85%) and fly ash (15-20%). Bottom ash can often be processed to recover metals and then used as an aggregate in construction applications like road base or concrete production. Fly ash, which may contain concentrated pollutants, requires special handling and is typically treated before disposal in specially designed landfills. Advanced technologies are being developed to further process and utilise both types of ash in beneficial applications.