Yes, wood is recyclable and is widely recycled in the UK, and remarkably high percentages of waste wood are processed annually. Wood can be reused in so many ways. It can be shredded into chips for animal bedding, mulch, or energy production, or turned into new products like animal bedding, MDF, and landscaping materials. However, check your local authority website for wood recycling instructions. It should not be placed in household recycling bins. In most districts, it should be taken to household waste recycling centres (HWRCs), and businesses should arrange for it to be collected by licensed waste management companies.

Key Takeaways Answering: Is Wood Recyclable?

- Wood is generally recyclable, but treated, painted, or composite woods require special handling and may not be accepted at standard recycling facilities.

- Recycling one ton of wood saves approximately 17 trees and prevents the release of about 1 ton of carbon dioxide.

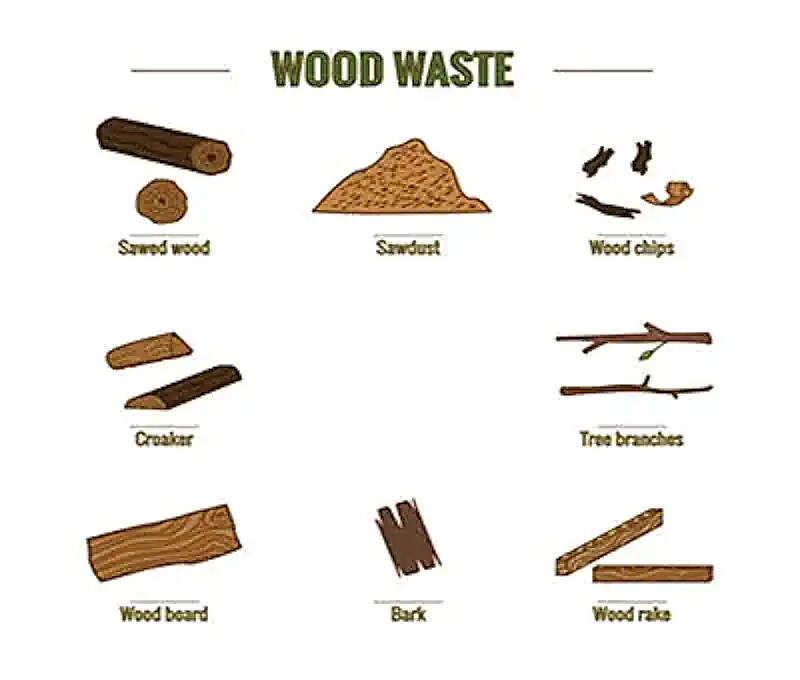

- Different grades of wood waste (A through D) determine how wood can be recycled or repurposed.

- Always remove nails, screws, and other metal hardware before attempting to recycle wood materials.

- For wood that can't be recycled, creative reuse projects or proper disposal at specialised facilities are environmentally responsible alternatives.

Is Wood Recyclable? Yes, wood is recyclable—but not all wood is created equal when it comes to the recycling process. Understanding which types of wood can be recycled and how to properly prepare them makes a significant difference in our environmental impact. With proper sorting and handling, recycled wood can find new life in everything from mulch to manufactured wood products, keeping valuable materials out of our landfills.

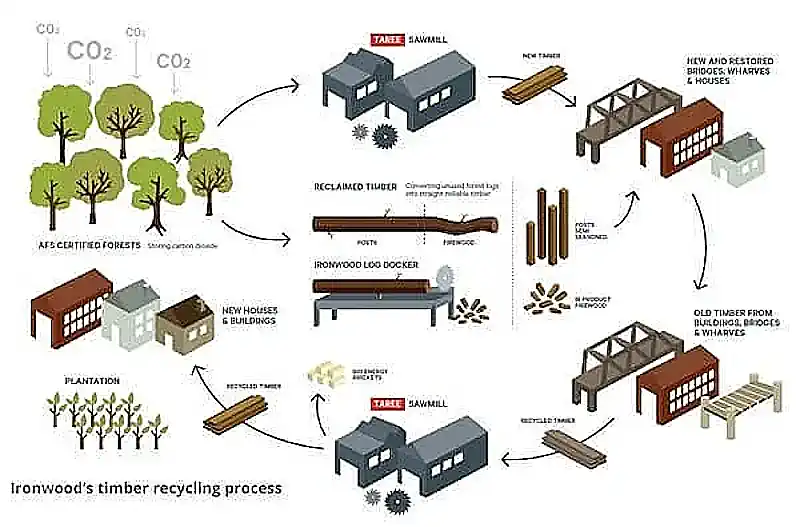

The journey of wood recycling is more complex than many realise, with different grades requiring different processing methods. When done correctly, wood recycling supports a circular economy that reduces deforestation and carbon emissions while creating sustainable materials for future use. Global Bioenergy experts have found that recycling wood is one of the most effective ways to reduce waste in the construction and demolition industries, which account for a significant portion of landfill materials.

Article-at-a-Glance

This comprehensive guide covers everything from identifying recyclable wood types to finding local recycling facilities and creative reuse ideas for wood that can't be traditionally recycled. We'll explore the environmental benefits, explain the grading system used by recycling facilities, and provide practical advice for handling different wood materials.

Whether you're a homeowner with leftover lumber, a contractor managing construction waste, or simply someone looking to make more environmentally conscious disposal decisions, this guide will help you navigate the wood recycling landscape.

Yes, Wood Is Recyclable – But There's a Catch

Wood recycling isn't as straightforward as tossing a cardboard box in your curbside bin. The recyclability of wood depends largely on how it was treated, what it was used for, and whether it contains any non-wood components.

Clean, untreated wood, like raw lumber scraps, tree trimmings, and unpainted wooden furniture, can generally be recycled with ease. However, wood that has been treated with chemicals, painted, stained, or combined with other materials presents significant challenges for recycling facilities.

The distinction between recyclable and non-recyclable wood matters because improper disposal can lead to environmental contamination or rejected loads at recycling facilities. When treated wood ends up in mulch or compost, the chemicals can leach into soil and waterways, causing environmental damage. Understanding these differences is the first step toward responsible wood disposal and recycling.

“Lumber & Clean Wood Recycling Services …” from www.evergro-org.com and used with no modifications.

Wood Recycling: Environmental Impact and Importance

Wood recycling stands at the intersection of waste management and forest conservation. By diverting wood waste from landfills, we not only save valuable landfill space but also reduce the demand for virgin timber. This creates a ripple effect of environmental benefits, from preserving forest habitats to reducing carbon emissions associated with logging, processing, and transporting new wood.

The environmental mathematics of wood recycling are compelling. For every ton of wood recycled, we save approximately 17 trees from being harvested. Additionally, wood decomposing in landfills produces methane—a greenhouse gas roughly 25 times more potent than carbon dioxide—making proper wood disposal an important climate action.

The Deforestation Problem: 42 Million Trees Cut Daily

Our planet loses approximately 42 million trees every day to deforestation, with lumber production being a significant contributor to this alarming statistic. This massive loss affects biodiversity, soil health, and climate stability on a global scale. Forest ecosystems support roughly 80% of terrestrial biodiversity and play a crucial role in carbon sequestration—the natural process of removing carbon dioxide from the atmosphere.

Wood recycling directly counters deforestation by extending the usable life of wood products and reducing the need for new timber. When we recycle or repurpose wood, we're essentially buying time for forest regrowth and recovery. This creates a more sustainable cycle of wood use that aligns with the natural regenerative capacity of forest ecosystems.

“Is Wood Recyclable” – Best Waste Management Best Practices

To understand more about sustainable practices, you might explore waste management best practices.

- Deforestation contributes to approximately 15% of global greenhouse gas emissions

- The construction industry alone accounts for about 40% of global timber consumption

- Recycling one ton of wood saves the equivalent of 1.38 tons of carbon dioxide

- Wood waste accounts for roughly 10% of the material in landfills

- Properly managed forests can regenerate within 40-100 years, depending on species

The connection between our daily choices about wood disposal and global deforestation may not always be apparent, but every piece of wood diverted from landfills and into the recycling stream contributes to forest conservation. By developing the habit of recycling wood whenever possible, we participate in a larger movement toward sustainable resource management and environmental stewardship.

The Wood Recycling Process

Wood recycling transforms discarded timber into valuable resources through a multi-stage process that begins the moment wood waste leaves your home or construction site. Understanding this process helps ensure your wood waste reaches the appropriate facility and gets properly processed for its next life. The journey from waste to resource involves several critical steps that vary depending on the type and condition of the wood being recycled.

“Responsible Wood Disposal and the …” from www.kaltimber.com and used with no modifications.

Collection and Sorting

The first step in wood recycling involves collecting and transporting wood waste to processing facilities. This happens through municipal collection services, private waste management companies, or direct drop-offs at recycling centres. Once at the facility, wood undergoes initial sorting to separate recyclable wood from contaminated or non-recyclable materials.

During sorting, workers or automated systems identify different wood types and separate them based on their recyclability. Clean lumber is directed to one processing stream, while treated wood may go to specialised handling areas. This critical sorting phase determines whether wood will become mulch, engineered wood products, biomass fuel, or face other disposal methods appropriate to its composition. For more information on wood recycling, check out GreenCitizen's guide on wood recyclability.

Wood Grading Systems Explained

The wood recycling industry uses a standardised grading system to classify wood waste based on quality, contamination level, and potential uses. “Is Wood Recyclable?” depends a lot on the grades of the wood disposed.

Grade A wood is clean, untreated timber suitable for high-grade recycling into products like particleboard. Grade B includes slightly treated wood, like painted lumber, that can still be recycled but with more limitations.

Grade C encompasses treated wood requiring careful handling, while Grade D contains hazardous materials that need specialised disposal.

This grading system helps processors determine the most appropriate and environmentally responsible destination for each type of wood waste, aligning with best practices in waste management.

Processing Methods for Different Wood Types

Once sorted and graded, wood undergoes processing tailored to its future application. Clean wood typically goes through chipping or grinding to reduce it to uniform sizes for manufacturing or mulching. The processing equipment uses powerful machinery to break down everything from small branches to large timber beams into manageable pieces. For more details on recycling wood, you can refer to this “Is Wood Recyclable” comprehensive guide.

Treated wood requires different handling methods depending on the treatment chemicals present. Some facilities use advanced techniques to extract or neutralise harmful substances, while others direct these materials to specialised waste-to-energy facilities designed to safely combust treated wood. The technological sophistication of these processes continues to evolve, making it possible to recycle an increasingly diverse range of wood products.

“Recycling Tips for Better Results: ” Is Wood Recyclable -What the beaver would say!” from www.recycleannarbor.org and used with no modifications.

Where to Recycle Wood Near You

- Municipal recycling centres that accept yard waste and clean wood

- Construction and demolition waste facilities specialising in building materials

- Specialised wood recycling companies that focus exclusively on timber products

- Biomass energy plants that convert wood waste to electricity

- Community woodworking shops that accept donations of usable lumber

Finding the right facility for your wood waste depends on both the type of wood you're disposing of and your location. Urban areas typically offer more recycling options than rural communities, though specialised services exist throughout most regions. Before loading up your vehicle, call ahead to confirm acceptance policies, as these can change based on capacity and market conditions.

Many locations offer different services for residential versus commercial quantities of wood waste. Homeowners with small amounts might find municipal transfer stations most convenient, while contractors with truckloads may need construction waste facilities with scales and higher capacity. Some facilities charge disposal fees, while others offer free drop-off for certain wood types that have market value. To better understand these processes, you can explore waste management best practices for handling wood waste efficiently.

Online resources like Earth911.com and local government websites maintain databases of recycling facilities searchable by material type and zip code. These tools can help you quickly locate the nearest appropriate facility for your specific wood waste. For unusual or difficult-to-recycle wood items, calling your local solid waste department can provide guidance on specialised disposal options.

Local Recycling Centres That Accept Wood

Community recycling centres serve as convenient drop-off points for residents with moderate amounts of wood waste. These facilities typically accept clean lumber, branches, and untreated wood products. Many operate as part of broader municipal recycling programs, with regular hours and clear guidelines about acceptable materials.

When visiting local recycling centres, prepare your wood waste by removing all non-wood components like nails, hinges, and plastic laminates. Most centres require wood to be cut to specific maximum dimensions (typically 4-6 feet in length) to facilitate handling. Check whether the facility accepts both hardwood and softwood, as some have restrictions based on their processing equipment or end markets.

Drop-Off Stations for Construction Waste

Construction and demolition (C&D) waste facilities specialise in processing building materials, including substantial quantities of wood waste. These operations handle everything from demolition debris to new construction scraps, with sophisticated sorting systems to maximise recycling rates. Most C&D facilities charge by weight or volume, with pricing structures that incentivise clean, separated loads over mixed construction waste. For more insights into waste processing, check out our guide on waste management best practices.

Free Wood Disposal Options

Several options exist for disposing of wood at no cost, particularly for clean, usable lumber or decorative wood pieces. Furniture banks, habitat restoration projects, community woodworking shops, and artist collectives often welcome donations of quality wood. Online platforms like Freecycle, Craigslist's free section, and local buy-nothing groups connect wood owners with people eager to repurpose materials, creating a direct form of recycling that bypasses processing facilities altogether.

Creative Ways to Reuse Wood at Home

Before sending wood to recycling facilities, consider whether it might have a second life right in your own home or garden. Reusing wood directly conserves even more energy than recycling, as it skips the resource-intensive processing steps. From simple storage solutions to elaborate furniture projects, wood's versatility makes it perfect for DIY reuse. Even small scraps can find purpose in creative projects, reducing waste while adding character to your living space.

“King Gong | Is Wood Recyclable? Can I …” from kinggong.com.au and used with no modifications.

DIY Furniture Projects from Scrap Wood

- Floating shelves from reclaimed planks or old floorboards

- Rustic coffee tables from pallets or barn wood

- Custom picture frames from trim pieces and moulding

- Plant stands and side tables from scrap lumber

- Wall art and decorative pieces from unique wood cutoffs

Transforming scrap wood into furniture connects us with the traditional craftsmanship of woodworking while giving materials a new purpose. Even beginners can tackle simple projects using basic tools and online tutorials. The imperfections in recycled wood often enhance its character, creating pieces with history and unique visual appeal that mass-produced furniture lacks.

Before starting furniture projects with recycled wood, ensure the material hasn't been treated with harmful chemicals if it will be used indoors. Light sanding removes surface contaminants and provides a clean base for finishes. Incorporate the natural patina of aged wood where possible, as these marks tell the story of the material's previous life and add authenticity to your creations.

Joining different wood types creates striking visual contrasts while making use of oddly-sized scraps. Consider combining light maple with dark walnut, or pairing smooth-planed surfaces with more rustic textures. This approach not only maximises material usage but also produces one-of-a-kind pieces with designer appeal at minimal cost.

Garden Uses for Old Wood

The garden offers countless opportunities for repurposing wood that may not be suitable for indoor projects. Raised garden beds, compost bins, trellises, and decorative borders transform wood waste into productive garden infrastructure. Even wood that has been treated or painted can often find appropriate outdoor applications where it won't contact soil used for food production. For more insights on recycling wood, check out this guide on wood recycling.

Untreated logs and branches create valuable habitat features in naturalistic gardens, supporting beneficial insects and small wildlife. As these pieces gradually decompose, they return nutrients to the soil in a natural cycling process. Strategically placed wood in gardens can also help with erosion control, moisture retention, and creating microclimates for sensitive plants.

Wood Chip Applications

Wood chips represent one of the most versatile forms of recycled wood, with applications ranging from garden mulch to animal bedding. Creating your own wood chips from branches and scrap wood requires a chipper (often available for rent), but it transforms awkward wood waste into a useful resource. A 3-4 inch layer of wood chip mulch suppresses weeds, retains soil moisture, and gradually improves soil structure as it breaks down. Discover more ideas for reducing your own waste and saving money.

Beyond traditional mulching, wood chips can create permeable garden pathways, serve as playground surfacing, or form the carbon component in compost piles. When sourcing wood chips, avoid those made from treated lumber if they'll be used around edible plants or in areas where children play. Many tree services offer free wood chips to homeowners willing to accept a full truckload, turning what would be a disposal challenge for them into a resource for your property. For more ideas on sustainability, explore ways to reduce your own waste and save money.

Common Wood Recycling Mistakes to Avoid

Even with the best intentions, wood recycling efforts can be undermined by common mistakes that contaminate the recycling stream. The most frequent error is failing to properly separate different wood types before disposal. Mixing treated lumber with clean wood can contaminate entire batches of recycled material, potentially rendering it unusable for many applications. Always sort wood waste according to treatment status and check with your local facility about their specific requirements for separation. For more information on waste management best practices, check out this guide on waste management.

Another common mistake is neglecting to remove metal hardware before recycling. Nails, screws, hinges, and other metal components can damage processing equipment and create safety hazards for workers. Take the time to remove these items, collecting them for separate metal recycling. For embedded fasteners that cannot be removed, inform the recycling facility so they can direct the material to appropriate processing equipment designed to handle these contaminants.

Mixing Treated and Untreated Wood

One of the most damaging mistakes in wood recycling is mixing treated and untreated wood together. When chemically treated lumber contaminates clean wood, it can render entire batches unusable for many applications. The chemicals in pressure-treated wood can leach into mulch or compost made from mixed batches, potentially harming plants and contaminating soil.

The financial impact of contaminated wood loads can be significant, too. Many recycling facilities will reject mixed loads or charge higher processing fees, as they must implement additional sorting and handling procedures. Some facilities even perform random chemical testing on incoming wood, and if treatment chemicals are detected in supposedly clean wood, the entire load may be diverted to landfill—exactly the outcome recycling aims to prevent.

Not Removing Metal Hardware First

Metal hardware poses serious problems for wood recycling equipment and processes. Nails, screws, hinges, brackets, and other metal components can damage industrial chippers and grinders, creating costly repairs and dangerous situations for workers. Most recycling facilities require that all visible hardware be removed before wood is accepted for processing. For more on waste management, check out our waste management best practices guide.

- Use a hammer or pry bar to remove visible nails and screws

- Check for hidden fasteners in joints and connections

- Use a metal detector on larger pieces when possible

- Collect removed hardware for separate metal recycling

- Inform facility staff about any metal you couldn't remove

The time invested in hardware removal pays dividends in the recycling process. Clean wood free of metal contaminants can be processed more efficiently and safely, resulting in higher-quality recycled products. Many recycling facilities will offer discounted disposal rates for properly prepared wood that requires minimal additional processing.

For particularly hardware-heavy items like furniture or cabinetry, consider dismantling pieces into their component parts before recycling. This not only makes metal removal easier but also allows you to separate different wood types that might require different recycling streams. Items like drawer slides, hinges, and decorative hardware often have value as scrap metal or can be reused in other projects. If you're interested in reducing waste and saving money, check out these ideas for reducing your own waste.

When hardware removal proves impossible—as with some heavily nailed pallets or construction debris—contact your local recycling facility for guidance. Some operations have specialised equipment designed to separate metal during processing, though this capability varies widely between facilities. Always call ahead to confirm acceptance policies rather than assuming all locations can handle metal-contaminated wood.

Benefits of Wood Recycling

Wood recycling delivers a remarkable trifecta of environmental, economic, and social benefits that extend far beyond simply keeping materials out of landfills. By establishing a circular lifecycle for wood products, recycling reduces pressure on forests, decreases energy consumption, minimises carbon emissions, creates jobs, and produces cost-effective materials for various industries. These interconnected benefits create a compelling case for prioritising wood recycling at both individual and systemic levels.

Reduced Need for Virgin Timber

Every piece of wood recycled means less demand for freshly harvested trees. This direct relationship between recycling and forest conservation helps protect vulnerable ecosystems and the wildlife that depends on them. In commercial forestry, it typically takes 40-100 years to regrow trees to harvest size, but recycling extends the useful life of wood indefinitely, giving forests the time they need to regenerate naturally. Reducing virgin timber demand also preserves old-growth forests that store massive amounts of carbon and support unique biodiversity not found in younger woodlands.

Energy Savings Compared to New Production

The energy equation for wood recycling shows impressive efficiency gains compared to producing new wood products. Harvesting trees requires heavy machinery, transportation to mills, energy-intensive kiln drying, and precision cutting—all energy-intensive processes. Recycling wood typically requires just collection, sorting, and repurposing or remanufacturing, resulting in substantially lower energy inputs.

These energy savings translate directly to reduced carbon emissions. Studies have shown that wood recycling can reduce energy use by up to 75% compared to new production, depending on the specific product and processing methods. For engineered wood products like particleboard and medium-density fiberboard (MDF), using recycled wood fibre instead of virgin material dramatically reduces both energy consumption and manufacturing costs.

The embodied energy in wood products—the total energy required for extraction, processing, manufacturing, and transportation—represents a significant investment of resources. Recycling preserves this embodied energy rather than starting the energy-intensive production cycle from scratch. This principle applies to all recycling but is particularly relevant for wood due to the long growth time required to produce new timber.

Wood Recycling Energy Comparison

1 ton of recycled wood saves approximately 4.3 million BTU of energy compared to virgin wood production—enough energy to power an average American home for nearly 2 weeks.

Economic Benefits and Job Creation

The wood recycling industry creates sustainable jobs throughout the collection, processing, and manufacturing chain. Unlike extractive industries that eventually deplete resources, recycling systems can operate indefinitely, providing stable employment in local communities. These jobs span multiple skill levels, from collection and sorting roles to technical positions operating sophisticated processing equipment and creative positions designing new products from recycled materials. According to the Recycling Economic Information Study, recycling and reuse activities generate approximately 10 jobs per 1,000 tons of material processed—significantly more employment than landfill disposal of the same materials.

Make Every Piece of Wood Count

Wood recycling represents a powerful opportunity to participate in circular economy principles that preserve resources for future generations. Whether you're a homeowner disposing of yard waste, a contractor managing construction debris, or a business handling wooden pallets and packaging, your decisions about wood disposal have lasting environmental impacts. By prioritising proper separation, preparation, and recycling of wood materials, you contribute to forest conservation, climate stability, and resource efficiency. Remember that even small actions—like removing nails before recycling or choosing recycled wood products—contribute to systemic change when adopted widely. Wood recycling transforms what was once considered waste into valuable resources, closing loops in our materials economy and demonstrating how thoughtful resource management can benefit both people and planet. Learn more about waste management best practices to further your impact.

Frequently Asked Questions

- What types of wood are recyclable?

- Where can I take wood for recycling?

- How do I prepare wood for recycling?

- Can painted or stained wood be recycled?

- What products are made from recycled wood?

These common questions reflect the complexity of wood recycling and the need for clear guidance. While general principles apply across regions, local regulations and facilities may have specific requirements that affect how you should handle wood waste in your area. When in doubt, contact your local solid waste authority or recycling coordinator for location-specific advice.

Understanding the answers to these questions empowers you to make environmentally responsible choices about wood disposal. As recycling technology continues to advance, more wood types may become recyclable in the future, expanding the potential for diverting this valuable material from landfills. Stay informed about changing capabilities in your area by periodically checking with local facilities or environmental agencies.

Can I put wood in my regular recycling bin?

No, wood typically cannot go in standard curbside recycling bins. These programs are generally designed for paper, certain plastics, glass, and metal—not wood materials. Placing wood in recycling bins can contaminate other recyclables and disrupt sorting systems at materials recovery facilities. Instead, wood requires specialised recycling through designated drop-off locations or collection programs specifically for yard waste or construction debris.

Some communities offer seasonal yard waste collection that accepts smaller branches and clean wood scraps, but these programs typically have strict size and quantity limitations. For larger quantities or dimensional lumber, most municipalities direct residents to transfer stations or specialised wood recycling facilities. Always check your local solid waste department's guidelines before disposing of wood, as placing it in the wrong collection stream can result in the entire load being rejected.

If you generate wood waste regularly, consider investing in a dedicated collection container for this material. Some waste management companies offer special collection services for businesses or contractors who produce significant amounts of wood waste. These arrangements typically involve scheduled pickups of separated wood materials destined for appropriate recycling facilities.

Wood Disposal Quick Reference

? Yard waste collection: Small branches, untreated lumber scraps (check size limits)

? Transfer stations: Larger wood pieces, construction lumber, natural wood

? Specialized recyclers: Treated wood, manufactured wood products

? Curbside recycling bins: Not acceptable in most programs

? Regular trash: Not recommended for any recyclable wood

How do I know if my wood is treated or untreated?

Identifying treated versus untreated wood is crucial for proper recycling, though it can sometimes be challenging. Pressure-treated lumber often has a greenish or brownish tint when new, which weathers to a greyish colour over time. Look for small incisions or tiny holes in a regular pattern along the surface—these are made during the treatment process to help chemicals penetrate the wood. In newer treated lumber, you might notice tags or end stamps with codes like “ACQ” or “CA” indicating treatment with alkaline copper quaternary or copper azole preservatives.

Older pressure-treated wood (pre-2004) might contain chromated copper arsenate (CCA), which poses significant environmental and health concerns if improperly handled. This older treated wood typically has a greenish tint that may have faded over time. If you're unsure about older wood from decks, playground equipment, or landscaping installed before 2004, it's safest to assume it might contain CCA and handle it accordingly, keeping it separate from other wood waste.

When in doubt about wood treatment status, err on the side of caution by assuming the wood is treated and following disposal guidelines for treated materials. Some recycling facilities offer testing services to determine treatment status, which may be worthwhile for large quantities of questionable wood. Remember that even naturally durable woods like cedar or redwood, which resist decay without chemical treatment, should be identified as untreated hardwoods for recycling purposes.

What products are made from recycled wood?

Recycled wood finds new life in an impressive array of products across multiple industries. Engineered wood products like particleboard, oriented strand board (OSB), and medium-density fiberboard (MDF) frequently incorporate recycled wood fibre, creating stable building materials from what would otherwise be waste. Landscaping products represent another major use, with recycled wood becoming mulch, soil amendments, and erosion control materials. The animal bedding industry uses clean wood chips for horse stalls, poultry houses, and small pet bedding, while biomass energy facilities convert wood waste to heat and electricity through controlled combustion or gasification processes. Innovation continues to expand these applications, with researchers developing new composites combining recycled wood with recycled plastics for durable outdoor products that resist weathering better than either material alone.

Is burning wood better than recycling it?

While burning wood can recover energy value, recycling generally offers greater environmental benefits in most situations. Combustion captures only the fuel value of wood, releasing stored carbon as carbon dioxide and potentially creating air quality issues. Recycling, by contrast, preserves both the material and its embodied carbon while reducing the need for virgin wood harvesting. Modern biomass energy facilities with advanced emission controls represent the most responsible approach to wood combustion when recycling isn't feasible, but they should generally be reserved for wood that cannot be recycled into new products.

The environmental calculus changes somewhat for treated or painted wood that cannot safely be recycled into most products. In these cases, properly controlled combustion in facilities designed to handle these materials may represent the best available option. These specialised waste-to-energy facilities have sophisticated emission control systems that can safely process treated wood while recovering energy value. However, home burning of treated wood is never appropriate due to the toxic compounds released during uncontrolled combustion.

How long does it take for wood to decompose naturally?

Natural wood decomposition times vary dramatically based on wood species, size, environmental conditions, and exposure to decomposer organisms. Small branches and soft woods may decompose in as little as 3-5 years in warm, humid environments with good soil contact. Larger hardwood logs can take 50-100 years to fully decompose in the same conditions. In dry environments or when wood is elevated off the ground, decomposition slows dramatically, with some desert-exposed wood lasting centuries.

Treated wood presents a special case, with preservative chemicals specifically designed to prevent natural decomposition. CCA-treated wood can resist decomposition for 30+ years, with the arsenic and chromium components persisting in soil long after the wood structure has eventually broken down. This extended environmental presence of treatment chemicals represents one of the main concerns with landfill disposal of treated wood.

The decomposition process also varies based on oxygen availability. In anaerobic landfill environments, wood decomposition produces methane—a potent greenhouse gas. This means that even untreated wood in landfills can contribute to climate change more significantly than if it were left to decompose naturally in aerobic conditions or, better yet, recycled into new products.

Wood recycling is an important aspect of waste management, as it helps reduce the amount of waste sent to landfills and conserves natural resources. When wood is recycled, it can be repurposed into new products, such as mulch, particleboard, and even biofuel. Understanding what waste management entails is crucial for effective recycling processes. By recycling wood, we not only minimise environmental impact but also promote sustainable practices for future generations.