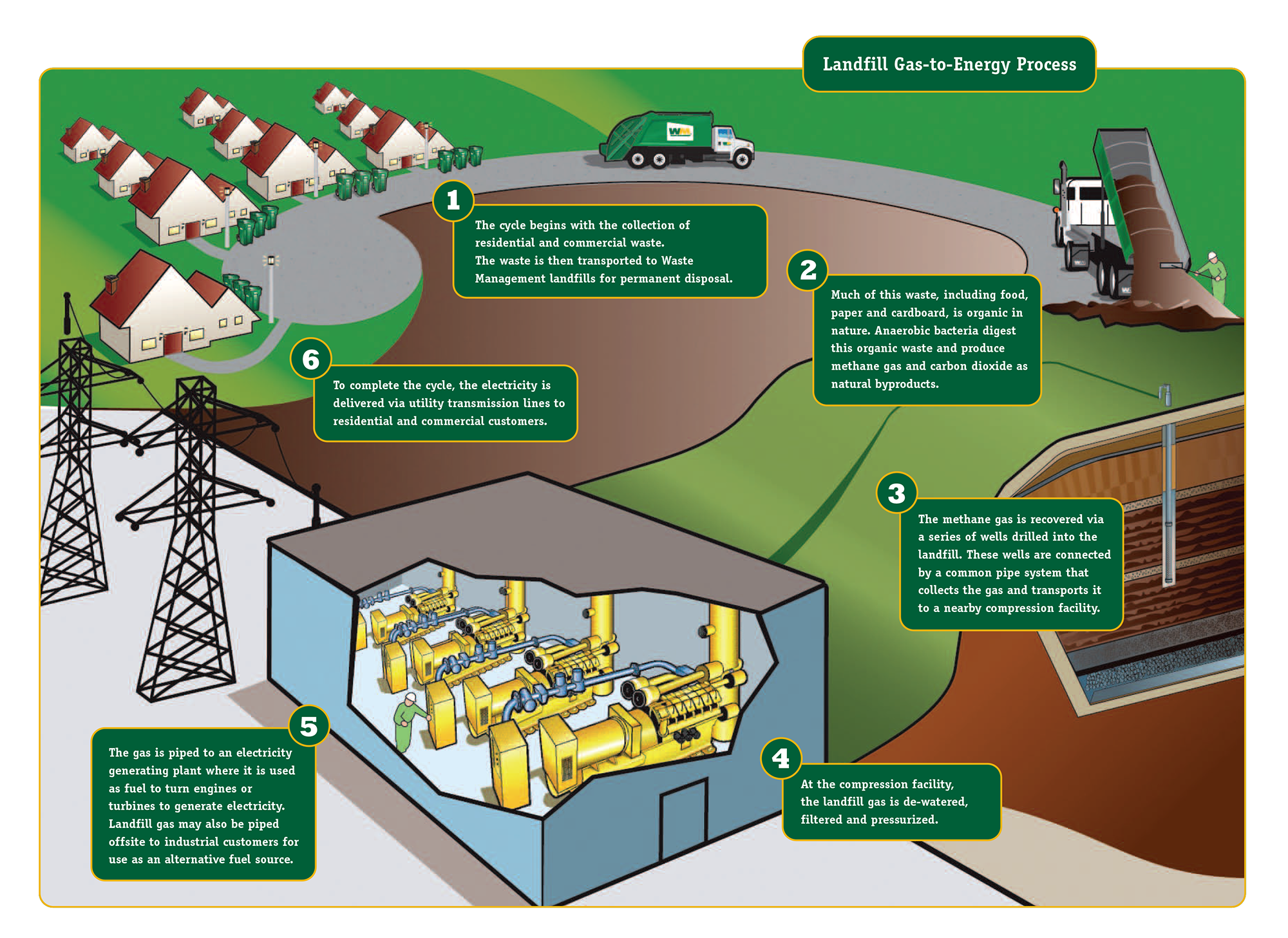

Landfill gas-to-energy is capturing naturally occurring methane and carbon dioxide from decomposing organic waste in landfills and converting it into usable energy, such as electricity, hot water, or transportation fuel. This process uses specialised systems of wells and pipes to collect the gas, which is then cleaned and processed using technologies like gas engines or turbines.

Read about this good news! Learn how LFG-to-energy projects provide a renewable energy source, reduce greenhouse gas emissions by preventing methane release, and can create local jobs and economic benefits.

Key Takeaways

- Landfill gas to energy systems convert harmful methane emissions into renewable energy, reducing greenhouse gases by 60-90% compared to uncaptured landfill emissions.

- Unlike solar or wind power, landfill gas provides consistent 24/7 baseload renewable energy, making it a reliable power source for communities.

- Three primary conversion methods exist: electricity generation, direct thermal use, and upgrading to renewable natural gas for pipeline injection.

- Implementing landfill gas projects creates local jobs, generates revenue for municipalities, and can attract businesses looking for sustainable energy sources.

- Modern collection systems use networks of wells and vacuum systems to safely extract gas that would otherwise contribute to climate change and pose safety hazards.

What if your local landfill could power thousands of homes while reducing greenhouse gas emissions? That's exactly what landfill gas energy solutions are accomplishing across the globe.

When organic waste decomposes, it produces a potent mixture of gases that, when captured properly, transforms environmental liability into valuable energy assets. Dearing Compressor & Pump has been at the forefront of developing efficient compression systems that make these renewable energy projects possible, helping communities turn waste management challenges into sustainable opportunities.

The transformation of trash to energy represents one of the most practical yet underutilized renewable energy sources available today. Each day, Americans generate over 4 pounds of waste per person, with much of it ending up in landfills where it begins a decades-long decomposition process. Rather than letting the resulting gases escape into our atmosphere, landfill gas energy systems harness this inevitable byproduct and put it to productive use.

“Landfill Gas to Energy at Lockwood – WM …” from wmnorcalnev.com and used with no modifications.

What Is Landfill Gas and Why It Matters

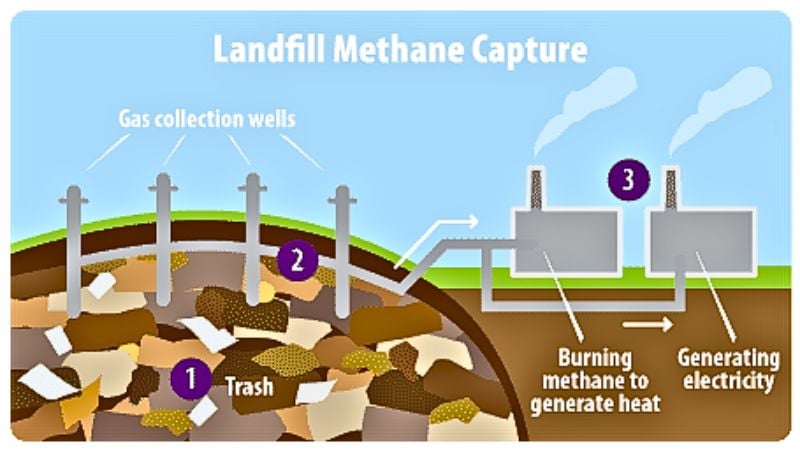

Landfill gas (LFG) is a natural byproduct of the decomposition of organic material in landfills. Composed of approximately 50% methane and 50% carbon dioxide with trace amounts of non-methane organic compounds, this gas forms when bacteria break down organic waste in an oxygen-free environment. What makes this especially significant is that methane is a greenhouse gas approximately 28-36 times more potent than carbon dioxide at trapping heat in the atmosphere over a 100-year period. When landfills release this gas unchecked, they contribute substantially to climate change.

COP Methane Pledges and the Climate Change Imperative to Capture and Use Landfill Gas

Recent climate summits have placed methane reduction at the center of global climate strategy. The Global Methane Pledge, launched at COP26 and strengthened in subsequent meetings, commits signatories to reducing methane emissions by at least 30% by 2030. Landfills represent one of the largest anthropogenic sources of methane emissions, making them prime targets for these reduction efforts. By capturing and utilizing landfill gas, municipalities can make significant contributions to meeting these international commitments while generating clean energy. This dual benefit positions landfill gas capture not just as an environmental necessity but as a practical solution that aligns with global climate objectives. For more details on the impacts of landfill regulations, visit our article on Scotland's landfill ban.

The Science Behind Methane Production in Landfills

The production of methane in landfills follows a predictable pattern tied to the stages of waste decomposition. Initially, aerobic bacteria consume oxygen while breaking down the waste. Once oxygen is depleted, anaerobic bacteria take over, producing methane, carbon dioxide, and other gases. This process typically begins within one year of waste placement and can continue for 20 years or more after a landfill closes. Peak gas production usually occurs between 5 to 7 years after waste deposition. The rate and volume of gas production depend on several factors, including waste composition, moisture content, landfill design, and local climate conditions. Understanding these variables is crucial for designing efficient gas collection systems and predicting energy generation potential.

Environmental Impact of Uncaptured Landfill Gas

When left uncaptured, landfill gas creates multiple environmental hazards beyond its climate impact. The methane component contributes significantly to ground-level ozone formation, which can cause respiratory issues and other health problems in surrounding communities. Non-methane compounds in the gas, such as volatile organic compounds (VOCs), can further degrade air quality, and some are known carcinogens. Additionally, migrating landfill gas can kill vegetation on and near landfill surfaces by displacing oxygen in the soil. In extreme cases, methane accumulation can create explosion hazards if the gas migrates into enclosed spaces. These environmental and safety risks make landfill gas collection not just environmentally beneficial but essential for community protection.

Landfills provide 24/7 Renewable Energy, Unlike Solar or Wind

One of the most compelling advantages of landfill gas energy is its reliability as a baseload power source. Unlike intermittent renewable energy sources such as solar and wind, which depend on weather conditions, landfill gas produces energy consistently 24 hours a day, 7 days a week. This constant generation capability eliminates the need for expensive energy storage solutions that other renewables often require. For utilities and grid operators, this predictable output makes integration into the power system straightforward and dependable. This reliability factor positions landfill gas energy as a valuable component in a diversified renewable energy portfolio, helping to stabilize the grid while maintaining environmental benefits.

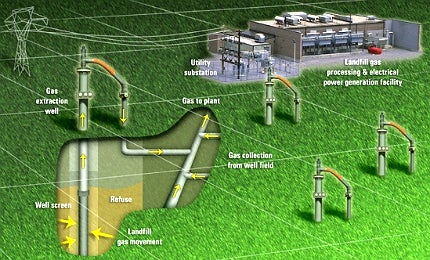

How Landfill Gas Collection Systems Work

Modern landfill gas collection systems employ sophisticated engineering to safely extract gas from decomposing waste. The process begins with the installation of a network of collection points throughout the landfill, connected by pipes that channel the gas to processing facilities. Vacuum systems provide the necessary pressure differential to draw the gas from the waste mass without allowing oxygen infiltration that could cause underground fires. These systems must be carefully designed to accommodate the settling and changing conditions within the landfill over decades of operation. The collected gas then undergoes treatment to remove moisture, particulates, and other impurities before it's ready for energy conversion. The entire system requires continuous monitoring to ensure optimal performance and safety.

“Harmful Gas to Renewable Energy …” from eepower.com and used with no modifications.

“Landfill gas itself represents a baseload resource of renewable energy. Think about some of the other renewable energy sources – wind and solar. Wind only produces power when the wind blows. Solar only produces power when the sun's out. But landfill gas projects… we run 24/7.”

- Collection wells are strategically placed throughout the landfill to maximize gas capture

- Header pipes connect individual wells to the main collection system

- Vacuum systems create negative pressure to draw gas from the waste mass

- Condensate management systems remove moisture from the gas

- Blowers move the collected gas to processing facilities

- Monitoring systems track gas quality and system performance

Well Installation and Gas Extraction Networks

The heart of any landfill gas collection system is its network of extraction wells. These wells typically consist of perforated pipes surrounded by gravel packing, extending vertically through the waste mass. A standard landfill might require dozens or even hundreds of these wells, strategically placed to maximize gas capture while minimizing oxygen intrusion. Engineers must account for the landfill's geometry, waste composition, and anticipated settlement patterns when designing the well layout. The spacing between wells generally ranges from 100 to 300 feet, depending on site conditions and regulatory requirements.

Each well connects to a lateral pipe network that channels the collected gas to a central header pipe. This interconnected system creates a web-like structure beneath the landfill's surface, ensuring comprehensive gas collection across the entire waste mass. The pipes must be sloped to allow condensate drainage, as the warm gas cools while traveling through the collection system. Modern systems include automated well monitoring that allows operators to adjust extraction rates at individual wells, optimizing the overall collection efficiency.

Installation typically occurs in phases as the landfill develops, with new wells added as waste cells reach capacity. This progressive approach allows for gas collection to begin early in a landfill's life cycle, maximizing energy production and environmental benefits. The well field requires regular expansion and adjustment throughout the landfill's active life and post-closure period, making flexibility a key design consideration.

Processing and Filtering the Captured Gas

Raw landfill gas contains numerous impurities that must be removed before energy conversion. The first step in processing involves condensate removal through knockout drums and dewatering systems that separate liquid from the gas stream. This is crucial because moisture can damage downstream equipment and reduce energy conversion efficiency. Next, particulate filters remove solid contaminants that could otherwise clog or damage system components. For more information on the benefits of capturing and converting landfill gas, you can visit this resource.

Depending on the intended use, the gas may undergo more extensive treatment. For electricity generation, basic filtration is often sufficient, whereas pipeline-quality gas requires advanced purification. Siloxanes, which form abrasive silica deposits when combusted, must be removed using activated carbon filtration or refrigeration systems. Hydrogen sulfide, which causes corrosion and produces sulfur dioxide when burned, is typically removed using iron sponge media or biological scrubbers. The level of treatment directly impacts both the capital cost of the project and the quality of the end product.

The processed gas then moves to a blower station that provides the pressure necessary to move it through the remainder of the system. Modern processing facilities include continuous monitoring equipment that analyzes gas composition in real-time, allowing operators to adjust treatment processes as needed to maintain quality standards.

Monitoring and Maintenance Requirements

Effective landfill gas systems demand rigorous monitoring and maintenance protocols. Field technicians regularly measure gas flow rates, composition, temperature, and pressure at individual wells and throughout the collection network. These measurements help identify areas of declining production, potential air intrusion, or collection inefficiency. Advanced systems incorporate telemetry that transmits real-time data to control centers, enabling rapid response to changing conditions.

Maintenance activities include clearing condensate blockages, repairing damaged pipes, adjusting well vacuum levels, and servicing blowers and flares. System components exposed to the corrosive nature of landfill gas require frequent inspection and occasional replacement. The landfill surface must be regularly examined for cracks or settlement that might compromise the gas collection efficiency or indicate underground problems.

Regulatory compliance adds another layer of monitoring requirements. Most landfill gas systems operate under permits that mandate specific performance standards and reporting protocols. Surface emission monitoring typically occurs quarterly, with technicians walking the landfill surface with portable methane detectors to identify potential leaks. These comprehensive monitoring and maintenance activities represent a significant operational commitment but are essential for maximizing energy production and environmental benefits.

3 Ways to Convert Landfill Gas into Usable Energy

Once captured and processed, landfill gas can be converted into energy through multiple pathways, each offering distinct advantages depending on local conditions and market needs. The versatility of landfill gas as an energy resource makes it adaptable to various scenarios, from rural landfills with limited infrastructure to urban facilities near industrial centers. Project developers must carefully evaluate these options to determine the most economically and environmentally beneficial approach for their specific circumstances. For more insights, explore the benefits of landfill gas energy projects.

1. Electricity Generation Through Combustion

The most common application for landfill gas is electricity generation through combustion engines or turbines. Internal combustion engines, typically ranging from 1 to 3 megawatts in capacity, offer excellent efficiency for medium-sized projects and can be installed incrementally as gas production increases. These engines operate similarly to natural gas generators but are specially designed to handle the lower energy content and variable composition of landfill gas. For more insights into the economic aspects of landfill operations, you can explore landfill gate fees.

For larger landfills with substantial gas flow, gas turbines provide economies of scale, with individual units capable of generating 5 megawatts or more. Though less flexible than reciprocating engines, turbines offer lower maintenance costs and emissions. Some facilities employ combined cycle systems that capture waste heat from the combustion process to generate additional electricity or provide thermal energy, boosting overall efficiency to over 80%.

The electricity produced can be used on-site to power landfill operations or exported to the grid through interconnection agreements with local utilities. Many projects qualify for renewable energy credits or other incentives that enhance their economic viability. A typical medium-sized landfill generating 1,500 standard cubic feet per minute of gas can produce enough electricity to power approximately 1,900 homes, making a significant contribution to local renewable energy portfolios.

2. Direct-Use Applications for Nearby Facilities

Direct-use applications represent one of the most efficient ways to utilize landfill gas energy, with minimal processing requirements and conversion losses. In these systems, minimally treated gas is piped directly to a nearby facility where it replaces natural gas, propane, or other fuels in boilers, kilns, dryers, or other thermal applications. The economic viability of direct-use projects hinges primarily on proximity—ideally, the end user should be within 5 miles of the landfill to minimize pipeline costs and thermal losses.

Manufacturing facilities with high thermal energy demands make excellent partners for direct-use projects. Brick manufacturers, cement kilns, glass producers, and food processors can all utilize landfill gas in their existing equipment with minimal modifications. These industries often operate continuously, providing a steady demand that matches the consistent supply characteristics of landfill gas.

Institutional users represent another promising market for direct-use applications. Universities, hospitals, and government complexes with central heating systems can integrate landfill gas into their energy mix, often as part of broader sustainability initiatives. These arrangements typically involve long-term contracts that provide price stability for both the landfill operator and the end user, creating mutually beneficial partnerships.

Greenhouse operations have emerged as particularly suitable direct-use applications. The combination of heat, electricity, and carbon dioxide (from controlled combustion) creates an ideal environment for plant growth. Several innovative projects have co-located greenhouse operations adjacent to landfills, utilizing all aspects of the energy resource while minimizing transportation requirements.

- Boilers and furnaces for industrial process heat

- Kilns for cement, lime, and brick manufacturing

- Infrared heaters for direct drying applications

- Greenhouse heating systems with CO? enrichment

- District heating networks for institutional campuses

“Waste-to-energy plants – how they work …” from www.power-technology.com and used with no modifications.

3. Renewable Natural Gas Production for Pipeline Injection

The fastest-growing segment of the landfill gas market involves upgrading LFG to renewable natural gas (RNG) that meets pipeline quality standards. This process removes carbon dioxide, nitrogen, oxygen, and trace contaminants to produce biomethane with 96-98% methane content—virtually indistinguishable from conventional natural gas. While requiring the most extensive processing, RNG offers the highest value product and greatest flexibility, as it can be injected into existing natural gas infrastructure for use anywhere in the connected system.

| Component | Raw Landfill Gas | Pipeline-Quality RNG |

|---|---|---|

| Methane (CH?) | 45-55% | 96-98% |

| Carbon Dioxide (CO?) | 30-40% | <2% |

| Nitrogen (N?) | 5-15% | <3% |

| Oxygen (O?) | 0-2% | <0.2% |

| Hydrogen Sulfide (H?S) | 0-2,000 ppm | <4 ppm |

| Siloxanes | 0-50 mg/m³ | <0.1 mg/m³ |

Several purification technologies compete in the RNG space, with membrane separation and pressure swing adsorption (PSA) currently dominating the market. Membrane systems use selective permeation to separate methane from other gases, while PSA employs specialized adsorbent materials that preferentially capture contaminants under pressure. Water scrubbing represents another common approach, particularly effective for removing carbon dioxide. The choice of technology depends on gas composition, flow rate, desired purity, and economic considerations.

The transportation sector has become a primary market for RNG through natural gas vehicle fleets. When used as vehicle fuel, RNG qualifies for valuable environmental credits under both the federal Renewable Fuel Standard and state-level programs like California's Low Carbon Fuel Standard. These incentives can increase the effective value of RNG to over $30 per million BTU—several times the commodity value of conventional natural gas—making even smaller landfill gas projects economically viable.

Utilities increasingly incorporate RNG into their supply portfolios to meet renewable energy targets and carbon reduction goals. Many offer voluntary green gas programs that allow customers to purchase RNG attributes, similar to green electricity programs. Some states have implemented renewable gas standards that require utilities to source a percentage of their gas supply from renewable sources, creating guaranteed markets for landfill-derived RNG.

Environmental Benefits That Make a Real Difference

The environmental advantages of landfill gas energy systems extend far beyond renewable energy production. By capturing a potent greenhouse gas that would otherwise escape into the atmosphere, these projects deliver immediate climate benefits. According to EPA calculations, a medium-sized landfill gas project can prevent emissions equivalent to removing 32,000 cars from the road. This direct impact on climate change mitigation represents one of the most cost-effective carbon reduction strategies available today.

Beyond greenhouse gas reduction, landfill gas projects help transform waste management facilities from environmental liabilities into community assets. Modern landfill gas systems effectively eliminate odors that typically prompt neighbor complaints, while simultaneously reducing the migration of non-methane organic compounds that can contaminate groundwater. The comprehensive environmental improvements created by these systems help landfill operators maintain positive relationships with surrounding communities while fulfilling their environmental stewardship responsibilities.

Greenhouse Gas Reduction Metrics

The climate impact of landfill gas projects can be quantified through standardized metrics that provide powerful evidence of their environmental value. According to the EPA's Landfill Methane Outreach Program, a typical 3 MW landfill gas electricity project reduces greenhouse gas emissions by approximately 34,700 metric tons of carbon dioxide equivalent annually. This substantial reduction occurs through two mechanisms: directly preventing methane release and offsetting fossil fuel consumption. When combined, these effects make landfill gas projects among the most impactful carbon reduction strategies available in the waste management sector.

The EPA offers a free Landfill Gas Energy Benefits Calculator that helps quantify these environmental benefits for specific projects. This tool converts technical parameters like gas flow rate and methane content into easily understood equivalents, such as cars removed from the road or acres of forest planted. For example, a medium-sized landfill gas project generating 3 MW of electricity provides annual greenhouse gas reductions equivalent to planting approximately 32,000 acres of forest or removing over 34,000 cars from the road. These compelling metrics help stakeholders understand the true environmental value of these projects beyond simple energy production figures.

Life cycle assessment studies consistently demonstrate that landfill gas energy systems provide net environmental benefits across multiple impact categories. Even accounting for the emissions from equipment manufacturing, installation, and operation, these projects deliver positive outcomes for global warming potential, acidification, and resource depletion. The most significant benefits occur when landfill gas displaces coal-fired electricity or diesel fuel, though substantial advantages remain even when compared to natural gas alternatives.

Air Quality Improvements for Surrounding Communities

Beyond greenhouse gas reduction, landfill gas projects deliver meaningful air quality benefits to surrounding communities. Raw landfill gas contains numerous non-methane organic compounds (NMOCs) including volatile organic compounds like benzene, toluene, and vinyl chloride. When landfill gas is captured and combusted, these compounds are destroyed with destruction efficiencies typically exceeding 98%. This process significantly reduces local air pollutants that can contribute to respiratory problems, ground-level ozone formation, and various health concerns.

Studies of communities surrounding landfills with gas collection systems consistently show lower ambient levels of landfill-related air pollutants compared to similar facilities without such systems. The EPA estimates that a typical landfill gas project reduces NMOC emissions by approximately 150 tons annually. These reductions translate to measurable improvements in local air quality, particularly for vulnerable populations like children, the elderly, and those with respiratory conditions who disproportionately suffer from poor air quality.

The air quality benefits extend beyond the immediate vicinity of the landfill. By displacing conventional electricity generation, landfill gas energy systems help reduce regional emissions of criteria pollutants like nitrogen oxides, sulfur dioxide, and particulate matter. This broader impact makes these projects valuable contributors to regional air quality management plans, particularly in non-attainment areas struggling to meet federal air quality standards. For more information on related topics, explore waste separation methods and their role in environmental management.

“Landfill gas emissions monitoring …” from kunakair.com and used with no modifications.

Safety Enhancements Through Controlled Collection

Uncontrolled landfill gas presents significant safety hazards that properly designed collection systems effectively mitigate. Methane is highly flammable in concentrations between 5% and 15% in air, creating explosion risks if allowed to migrate and accumulate in confined spaces. Documented cases exist of methane migration causing explosions in buildings near landfills without adequate gas control systems. By maintaining negative pressure throughout the waste mass, modern collection systems prevent this dangerous lateral migration.

Beyond explosion hazards, landfill gas contains compounds that pose health risks through direct exposure. Hydrogen sulfide, a common component, causes respiratory irritation at low concentrations and can be fatal at high levels. Carbon dioxide, though less immediately dangerous, can create oxygen-deficient environments in low-lying areas near landfills. Collection systems dramatically reduce these risks by capturing the gas before it can affect surrounding properties.

The safety benefits extend to the landfill property itself. Proper gas management prevents underground fires that can smolder for years, damaging infrastructure and releasing toxic compounds. It also reduces stress on landfill covers by preventing pressure buildup that can cause cracking and subsequent water infiltration. These protective measures help maintain the structural integrity of the landfill while extending its useful life and reducing long-term maintenance requirements.

Economic Advantages of Landfill Gas Projects

The financial benefits of landfill gas energy systems extend far beyond simple energy sales. These projects create diverse revenue streams while simultaneously reducing operational costs and potential liabilities. For municipal landfill owners, these economic advantages can transform waste management from a cost center to a revenue generator, helping to stabilize budgets and reduce the financial burden on taxpayers.

Job Creation During Construction and Operation

Landfill gas energy projects generate significant employment opportunities throughout their lifecycle. During the construction phase, which typically lasts 8-12 months for a medium-sized project, dozens of workers are needed for well drilling, pipe installation, equipment assembly, and electrical work. These positions span various skill levels, from general laborers to specialized technicians, creating diverse employment opportunities within the community. A typical 3 MW project creates approximately 5-7 jobs per million dollars invested during construction, with approximately 75% of these positions filled from local labor pools. Learn more about ways to reduce, reuse, and recycle in related sectors.

Once operational, these facilities require permanent staff for monitoring, maintenance, and management. A medium-sized electricity generation project typically employs 2-3 full-time operators, while larger RNG facilities may require teams of 5-7 specialists. These permanent positions offer stable, well-paying jobs in the growing renewable energy sector, with transferable skills applicable across multiple industries. Additional indirect employment occurs through regular service contracts for specialized maintenance, environmental monitoring, and regulatory compliance activities.

The economic multiplier effect amplifies these direct employment benefits. Studies indicate that each direct job in renewable energy creates approximately 2.5 additional jobs in supporting industries and local service sectors. For communities struggling with economic transition or industrial decline, these projects provide valuable diversification while building workforce capacity in growing environmental and energy fields.

Revenue Generation for Local Governments

Landfill gas projects create multiple revenue streams that benefit local government budgets. For publicly owned landfills, energy sales provide direct income that can offset waste management costs or fund other municipal services. Even modest projects can generate hundreds of thousands of dollars annually through power purchase agreements or gas sales contracts. Some municipalities leverage these steady revenue streams to secure favorable financing for other infrastructure projects, effectively using landfill assets to improve their overall fiscal position.

Tax revenue represents another significant benefit, particularly for privately operated projects on public land. Property taxes on energy generation equipment, sales taxes on construction materials, and income taxes from project employment all flow to local and state governments. These revenue sources arrive without requiring additional public services, creating a net positive impact on government budgets. The predictable, long-term nature of these revenue streams helps municipalities plan effectively for future needs.

Environmental credits and incentives provide additional income potential beyond basic energy sales. Renewable energy credits, carbon offset credits, and transportation fuel credits can double or triple the effective value of landfill gas energy, particularly in states with aggressive climate policies. While these markets fluctuate, they consistently provide premium values for landfill gas projects due to their dual benefits of waste reduction and renewable energy production.

Cost Savings Compared to Traditional Energy Sources

Landfill gas energy offers compelling economic advantages when compared to conventional energy sources, particularly when accounting for full lifecycle costs. The fuel source—the gas itself—is essentially free, having been generated as a byproduct of waste disposal operations that would occur regardless of energy recovery. This fundamental advantage eliminates fuel price volatility that affects natural gas, coal, and petroleum-based generation, providing predictable operating costs over decades-long project lifespans.

The distributed nature of landfill gas generation creates additional cost advantages through reduced transmission requirements. Because these facilities are typically located near existing distribution infrastructure and load centers, they minimize the transmission losses and infrastructure costs associated with remote power generation. For on-site use applications, these advantages become even more pronounced, with some projects achieving payback periods under three years when displacing propane or fuel oil for process heat applications.

When regulatory compliance costs are considered, the economic case becomes even stronger. Many landfills are required to collect and control gas emissions regardless of beneficial use, typically through flaring. Energy recovery projects convert this compliance cost into a revenue opportunity, effectively transforming a liability into an asset. This dual-purpose nature makes landfill gas uniquely positioned among renewable energy options, as the primary infrastructure would be required regardless of energy production.

Attracting New Businesses to Communities

Innovative communities are leveraging landfill gas assets to attract new businesses seeking sustainable energy solutions. Companies with corporate sustainability goals increasingly prioritize renewable energy access when making facility siting decisions. A reliable source of renewable power or thermal energy can become a decisive factor in business attraction efforts, particularly for manufacturing operations with significant energy demands and corporate environmental commitments.

Several successful eco-industrial parks have developed around landfill gas energy resources. These specialized business parks offer below-market energy prices through direct gas utilization while providing companies with powerful sustainability credentials. Businesses ranging from greenhouses and food processors to data centers and manufacturing operations have established facilities specifically to access this renewable energy source. This clustering effect creates synergies and shared infrastructure that benefit all participating companies while maximizing the value of the energy resource.

The community branding advantages extend beyond direct energy users. Municipalities that successfully implement landfill gas projects gain recognition as environmental leaders, attracting businesses and residents who prioritize sustainability. This positive association helps counter the traditional negative perceptions of landfills, transforming them from unwanted necessities to valuable community assets that demonstrate environmental innovation and responsible resource management.

Real-World Success Stories

Across North America, hundreds of successful landfill gas energy projects demonstrate the practical benefits of this technology. These diverse implementations range from small municipal systems powering local government operations to large commercial facilities producing pipeline-quality renewable natural gas. Each success story offers valuable lessons for communities considering similar projects while providing empirical evidence of the environmental and economic benefits these systems deliver.

Erie Green Energy Project: Converting Waste to Power

The Erie Landfill Gas-to-Energy Project in Colorado exemplifies how medium-sized communities can successfully implement landfill gas energy solutions. This facility captures gas from approximately 2.8 million tons of decomposing waste at the Front Range Landfill to generate 3.2 megawatts of renewable electricity—enough to power approximately 3,000 homes. The project represents a successful public-private partnership between the municipality, the landfill operator, and an independent power producer who manages the energy generation equipment.

What makes this project particularly noteworthy is its role in helping the community meet its renewable energy goals. The electricity feeds directly into the local grid through a long-term power purchase agreement with the municipal utility, helping satisfy state renewable portfolio standards. The community benefits from improved environmental compliance, reduced odors, and the creation of skilled technical jobs that diversify the local economy. The project's success has inspired neighboring communities to evaluate their own landfills for similar opportunities, creating regional momentum for waste-to-energy initiatives.

The Erie project also demonstrates the value of phased implementation. The system began with a single generator and has expanded twice as gas production increased, allowing capital costs to be spread over time while matching energy production to gas availability. This scalable approach minimizes financial risk while maximizing the resource utilization over the landfill's productive lifetime.

How Small Communities Have Implemented Successful Systems

Small communities face unique challenges in implementing landfill gas projects, including limited capital resources and smaller waste volumes. However, innovative approaches have overcome these barriers. The Town of Bourne, Massachusetts provides an instructive example with its modular landfill gas system serving a community of just 20,000 residents. Rather than pursuing conventional electricity generation, Bourne installed a direct-use system that pipes minimally processed gas to the town's municipal buildings, schools, and community center for heating purposes.

This approach dramatically reduced the initial capital investment while maximizing the economic value of the gas by directly displacing expensive heating oil. The project achieved a four-year payback period while reducing the town's heating costs by over 60%. By keeping the system simple and focusing on high-value applications, Bourne created a financially viable project despite its relatively small scale. The town's approach has become a model for similar communities throughout the Northeast, demonstrating that landfill gas projects can be scaled appropriately for smaller municipalities.

Other small communities have succeeded through collaborative regional approaches. In central Minnesota, three counties formed a cooperative to aggregate their landfill gas resources and jointly develop a processing facility that upgrades gas from multiple small landfills to pipeline quality. This shared infrastructure makes efficient use of capital while providing enough scale to justify the processing equipment. The cooperative structure allows each community to maintain local control while benefiting from the economies of scale typically only available to larger operations.

“Landfill Gas Monitoring in King County …” from www.aspectconsulting.com and used with no modifications.

Getting Started With Landfill Gas Energy

Implementing a landfill gas energy project requires careful planning and a systematic approach to resource assessment, partnership development, and regulatory compliance. While each project has unique characteristics based on local conditions, following established best practices significantly increases the likelihood of technical and economic success. The EPA's Landfill Methane Outreach Program provides comprehensive resources and technical assistance to help communities navigate this process effectively.

Assessing Your Landfill's Potential

- Waste-in-place analysis to determine total decomposing organic material

- Gas generation modeling using EPA LandGEM or similar tools

- Test well installation and gas composition analysis

- Site-specific evaluation of collection efficiency factors

- Energy market assessment for potential offtake arrangements

- Preliminary economic feasibility studies and sensitivity analysis

The first step in developing a landfill gas project involves a comprehensive assessment of the resource potential. This begins with calculating the total waste-in-place and estimating the organic fraction that will generate methane. Historical records of waste composition and deposition rates provide the foundation for this analysis, though site-specific testing yields the most accurate results. The EPA's LandGEM (Landfill Gas Emissions Model) offers a standardized methodology for estimating gas generation based on these inputs, producing projections of gas quantity and quality over time.

Once the theoretical gas production is established, field testing confirms these estimates and provides critical data on gas composition. Test wells installed at representative locations across the landfill allow for direct measurement of flow rates, methane content, and contaminant levels. This empirical data helps refine gas production models while identifying any unusual characteristics that might affect energy conversion options. Most projects require at least one year of monitoring to account for seasonal variations in gas production and establish reliable baseline data.

The final assessment phase examines potential energy applications and markets based on the confirmed gas resource. This analysis considers local electricity prices, natural gas markets, nearby thermal energy users, and available incentives to identify the highest-value utilization option. Preliminary economic models incorporating capital costs, operating expenses, and projected revenue streams establish the basic feasibility of various approaches. This comprehensive assessment provides the foundation for project development decisions and helps attract potential partners and financing.

Finding Partners and Funding Sources

Few landfill operators have the internal expertise and capital resources to independently develop energy projects, making partnerships essential for success. These collaborations typically involve technology providers who supply and often operate the energy conversion equipment, project developers who structure the business arrangements and secure financing, and energy offtakers who commit to purchasing the electricity or gas. The optimal partnership structure depends on the landfill owner's goals, risk tolerance, and desired level of involvement in project operations. Options range from simple land leases with minimal involvement to full ownership and operation of the energy system. For more information on managing landfill operations, consider exploring landfill gate fees and their impact on project financing.

Funding sources have diversified significantly as these projects have become more mainstream. Traditional infrastructure financing through municipal bonds remains common for publicly owned projects, offering low interest rates and long terms that match the project lifecycle. Commercial lenders increasingly offer specialized financing for renewable energy projects, particularly those with secured revenue through power purchase agreements or gas contracts. Federal programs including the Rural Energy for America Program, the Inflation Reduction Act's tax incentives, and various state-level grant programs can significantly improve project economics through direct funding or tax benefits. The optimal funding approach typically involves combining multiple sources to maximize incentives while maintaining a manageable risk profile. For more insights on managing project costs, consider understanding landfill gate fees.

Key Regulations and Permit Requirements

Regulatory compliance represents a critical aspect of landfill gas project development, involving multiple agencies with overlapping jurisdiction. Air quality permits constitute the most fundamental requirement, addressing both the collection system and the energy conversion equipment. These permits establish emission limits for criteria pollutants and hazardous air pollutants, typically requiring best available control technology for NOx, CO, and NMOCs. For larger projects or those in non-attainment areas, more stringent New Source Review requirements may apply, potentially requiring emission offsets or additional controls. Learn more about the benefits of landfill gas energy projects.

The Future Is Bright for Waste-to-Energy Solutions

The outlook for landfill gas energy continues to strengthen as technology advances, environmental regulations tighten, and markets increasingly value renewable energy. Technological innovations in gas purification, particularly for siloxane and nitrogen removal, are expanding the potential applications for landfill gas while reducing processing costs. Modular, scalable systems are making smaller projects economically viable, extending these benefits to communities previously unable to justify such investments. Meanwhile, advanced monitoring and control systems are improving collection efficiency and operational stability, maximizing energy production while minimizing environmental impact.

Market trends strongly favor continued growth in this sector. Corporate sustainability commitments drive demand for renewable natural gas and green electricity, creating premium markets for landfill-derived energy products. Transportation fleets increasingly adopt compressed natural gas vehicles fueled by renewable gas, leveraging valuable environmental credits while reducing emissions. Utilities facing renewable portfolio standards and carbon reduction mandates view landfill gas as a reliable, baseload component of their clean energy strategies. These converging factors create a robust market outlook that supports continued investment in waste-to-energy infrastructure.

Frequently Asked Questions

Communities and organisations considering landfill gas energy projects often have similar questions about these systems. The following answers address the most common inquiries based on empirical data and industry experience, helping stakeholders make informed decisions about potential implementations.

How much electricity can a typical landfill gas project generate?

Electricity generation capacity depends primarily on the size of the landfill and the quantity of decomposing waste. As a general rule of thumb, one million tons of waste-in-place can support approximately 0.5 to 1 megawatt of generating capacity. A medium-sized regional landfill containing 3-5 million tons of waste typically generates enough gas to power 2-4 megawatts of electrical capacity, sufficient for about 1,600-3,200 homes. Larger facilities serving major metropolitan areas may support 10-15 megawatts or more.

The relationship between waste volume and energy production isn't perfectly linear, as factors including waste composition, climate, and landfill design significantly influence gas generation rates. Modern landfills with engineered systems for leachate recirculation typically produce more gas per ton of waste than older facilities. Similarly, landfills in warmer, wetter climates generally achieve higher gas production rates than those in cold, dry regions due to accelerated biological decomposition.

Generation efficiency varies by conversion technology, with internal combustion engines typically achieving 30-35% electrical efficiency, gas turbines reaching 25-30%, and microturbines operating at 20-27%. Combined heat and power systems that utilise waste heat can achieve overall efficiencies of 70-80%, though this requires suitable thermal loads near the landfill. Most projects maintain some excess capacity or supplemental flaring capability to accommodate variations in gas production over time.

“Every megawatt of electricity generated from landfill gas prevents approximately 11,000 metric tons of CO? equivalent emissions annually. That's equal to the carbon sequestered by over 13,000 acres of U.S. forests in one year.” – EPA Landfill Methane Outreach Program

What happens to landfill gas if it's not captured for energy?

When landfill gas isn't captured for beneficial use, regulatory requirements typically mandate that it be collected and destroyed through flaring to reduce environmental impacts. Flaring converts methane to carbon dioxide through combustion, reducing its global warming potential by approximately 28-36 times, though this approach wastes the energy content.

In uncontrolled landfills or those too small to justify collection systems, the gas escapes to the atmosphere where it contributes to climate change, creates odor problems, and potentially poses safety hazards through migration. Many older or smaller landfills still release significant quantities of methane despite regulatory efforts, representing one of the largest anthropogenic sources of this potent greenhouse gas.

How long can a landfill produce usable gas after closure?

Gas production continues long after a landfill stops accepting waste, though production rates gradually decline over time. Most landfills maintain commercially viable gas flows for 15-20 years after closure, with some producing useful quantities for 30 years or more, depending on waste composition and site conditions.

The production curve typically peaks 5-7 years after waste placement and then declines at a rate of approximately 2-5% annually. Modern bioreactor landfills that actively manage moisture content may experience accelerated gas production initially but potentially shorter overall productive lifespans. To understand more about landfill operations, including landfill gate fees, explore further resources.

The extended production period creates both opportunities and challenges for energy project planning. Most energy conversion equipment has a useful life of 15-20 years, requiring careful timing of installation to maximise utilisation.

Some projects implement phased approaches, starting with larger capacity during peak production and gradually reducing capacity as gas flows decline. Others supplement declining landfill gas with natural gas or biogas from other sources to maintain consistent operation. Forward-thinking operators include provisions for equipment redeployment or downsizing in their initial project plans, ensuring economic viability throughout the landfill's productive lifetime.

Are there US tax incentives available for landfill gas energy projects?

Numerous tax incentives support landfill gas energy development at both the federal and state levels. The federal Investment Tax Credit (ITC) and Production Tax Credit (PTC) both apply to these projects, providing significant financial benefits. The Inflation Reduction Act of 2022 extended and expanded these incentives, making them more valuable for landfill gas projects, particularly those meeting domestic content and prevailing wage requirements.

Additional incentives include accelerated depreciation, tax-exempt bond financing for municipal projects, and various state-level property and sales tax exemptions. When combined, these incentives can reduce project costs by 30-50%, substantially improving economic returns and expanding the number of viable project opportunities.

How do landfill gas projects compare to other renewable energy sources?

Landfill gas energy offers several distinct advantages compared to other renewable sources. Most significantly, it provides baseload power—consistent, reliable energy production 24/7 regardless of weather conditions. This contrasts sharply with wind and solar, which produce intermittent power dependent on environmental conditions. This baseload characteristic makes landfill gas particularly valuable for grid stability and reliability, complementing rather than competing with other renewables in a balanced energy portfolio.