What is waste management? Let's get going straight away with a Waste Management Definition: Waste management includes the collection, transportation, treatment, and disposal of unwanted items from the source of creation to the point of final disposal. Its main objectives are to reduce negative impacts on the environment and human health by recycling, reusing, and reducing trash, with the ultimate goal of turning waste into a useful resource whenever feasible.

Key Takeaways

- Effective waste management starts with understanding the waste hierarchy – reduce, reuse, recycle, recover, and dispose – to minimize environmental impact.

- Conducting a comprehensive waste audit is the foundation of any successful waste management program, revealing opportunities for immediate improvement.

- Proper waste segregation can increase recycling rates by up to 25% and significantly reduce contamination issues.

- Regular staff training on waste protocols is essential, with organizations reporting up to 40% improvement in compliance after implementation.

- Waste management isn't just an environmental concern—businesses implementing best practices typically see 15-30% reduction in disposal costs.

Proper waste management isn't just about getting rid of trash—it's a comprehensive approach that protects our environment, conserves resources, and can even boost your bottom line. With global waste generation expected to increase by 70% by 2050, implementing effective waste management practices has never been more crucial. Whether you're managing waste for a large corporation, small business, or your own household, the principles remain the same: minimize what you produce and handle what remains responsibly.

What Is Waste Management? A Simple Definition for Real Results

Waste management encompasses all activities required to manage waste from its inception to its final disposal. This includes collection, transport, treatment, and disposal of waste, together with monitoring and regulation of the waste management process and waste-related laws. The goal is simple: reduce waste's environmental impact while maximizing resource recovery.

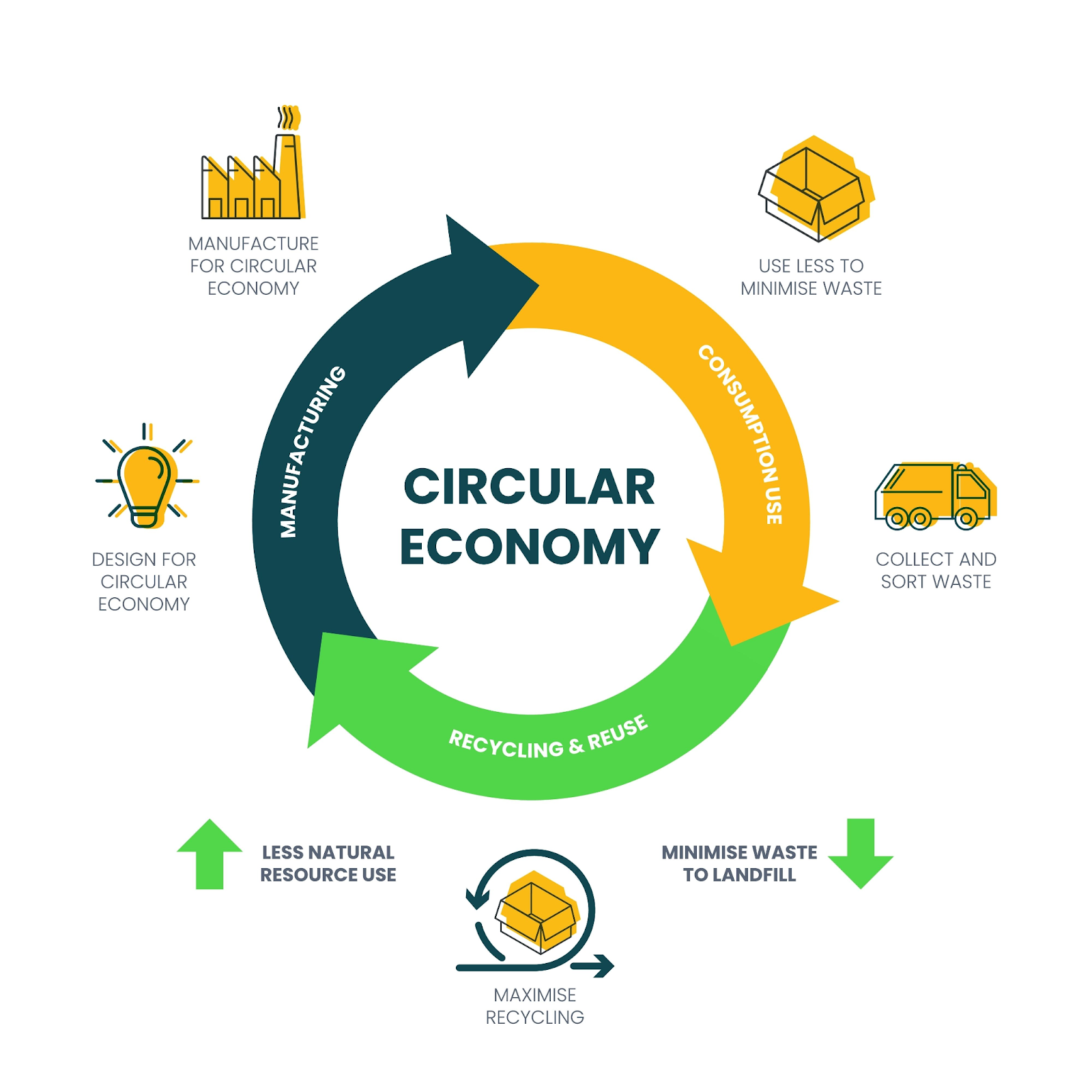

At its core, effective waste management aims to break the traditional “take-make-dispose” linear model in favor of circular approaches that keep materials in use for as long as possible. This shift not only reduces the strain on natural resources but also addresses growing landfill limitations and pollution concerns. Companies like WasteWise are pioneering innovative solutions that transform how we think about waste—not as something to discard, but as a resource with untapped potential.

Modern waste management extends beyond simple garbage collection to include sophisticated material recovery facilities, advanced recycling technologies, biological treatment methods, and energy recovery systems. The industry has evolved dramatically in recent decades, driven by environmental regulations, resource scarcity, and growing public awareness about waste's environmental impacts.

“The Importance of Sustainable Waste …” from acterra.org and used with no modifications.

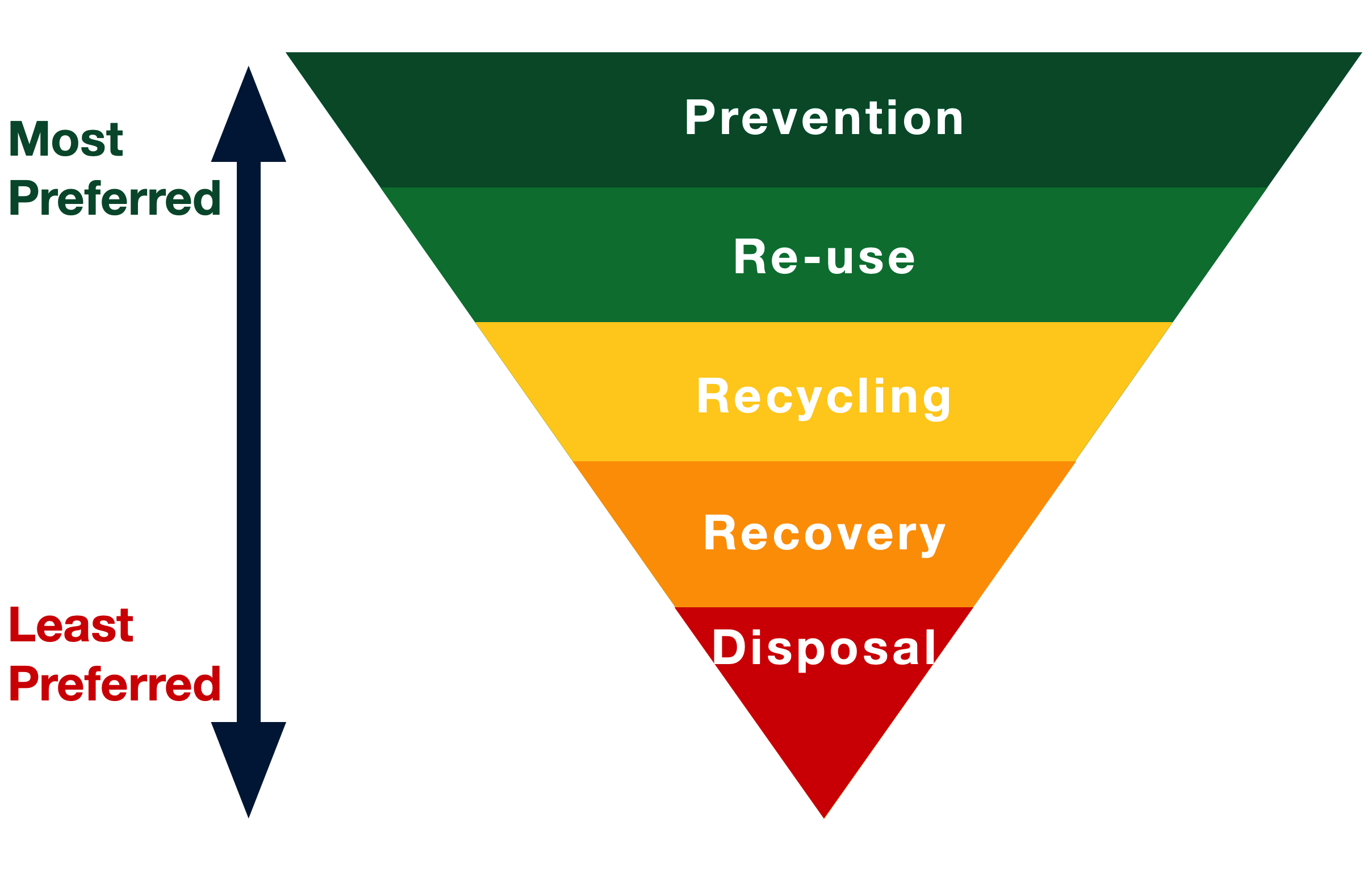

The Waste Hierarchy: Foundation of Effective Management

The waste hierarchy provides a framework for prioritizing waste management approaches according to their environmental impact. This five-tier model guides decision-making from most favorable (prevention) to least favorable (disposal) options.

“The waste hierarchy isn't just a theoretical model—it's a practical decision-making tool that can transform how organizations approach waste. When systematically applied, it drives both environmental and economic benefits. Understanding the waste separation methods is crucial for implementing this model effectively.”

Understanding this hierarchy is essential for anyone looking to implement best practices in waste management. Each level represents a different approach to handling materials, with the top levels focusing on preventing waste generation in the first place, such as through waste-to-energy companies.

“What is the Waste Hierarchy?” from ismwaste.co.uk and used with no modifications.

Reduce: Cutting Waste at the Source

Prevention sits at the top of the waste hierarchy because the most environmentally friendly waste is the waste that's never created. This approach involves designing products and processes that minimize waste generation from the start. For businesses, this might mean redesigning packaging to use less material, implementing paperless systems, or purchasing durable equipment with longer lifespans.

Waste reduction strategies often deliver the greatest environmental benefits while simultaneously reducing costs associated with purchasing, handling, and disposing of materials. For example, a manufacturing facility that optimizes its cutting processes to reduce material scraps can save on both raw material costs and waste disposal fees.

Simple reduction techniques include double-sided printing, purchasing concentrates rather than diluted products, and buying in bulk to reduce packaging waste. Even small changes, when implemented consistently, can lead to significant waste reduction over time.

Reuse: Extending Product Life

Reuse involves using items multiple times before discarding them, whether for their original purpose or something new. This approach maintains a product's value without requiring additional processing, saving energy and resources that would otherwise be needed for recycling or manufacturing new products.

In commercial settings, reuse might involve returnable shipping containers, refillable packaging systems, or repurposing obsolete equipment for alternative uses. For individuals, reusable shopping bags, water bottles, and food containers represent simple reuse strategies that reduce single-use waste.

The reuse economy has grown substantially in recent years, with repair cafés, second-hand markets, and product service systems (where consumers pay for the service a product provides rather than the product itself) becoming increasingly common. These models not only reduce waste but often create new business opportunities and community connections.

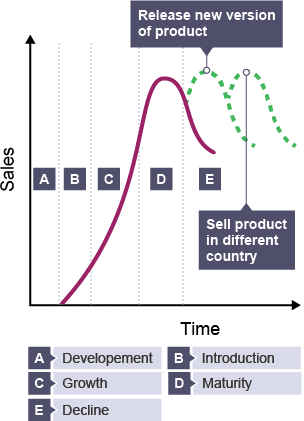

“Extending product life cycle – Product …” from www.bbc.co.uk and used with no modifications.

Recycle: Transforming Materials

Recycling converts waste materials into new products, reducing the need for virgin resources while diverting materials from landfills. While not as environmentally beneficial as reduction or reuse, recycling still plays a crucial role in sustainable waste management.

Effective recycling depends on proper segregation at the source—mixing incompatible materials can contaminate entire batches, rendering them unrecyclable. This highlights the importance of clear labeling on bins and comprehensive education for all waste generators. Understanding what can and cannot be recycled in your specific area is essential, as acceptance criteria vary widely between locations.

Different materials offer different recycling efficiencies. Metals like aluminum can be recycled indefinitely without quality degradation, while paper fibers can typically be recycled 5-7 times before becoming too short for papermaking. Plastics present more challenges, with some types being more readily recyclable than others.

Recover: Extracting Value from Waste

Recovery focuses on extracting value from waste materials that cannot be recycled. The most common form is energy recovery, where waste is processed to generate electricity, heat, or fuel. Waste-to-energy facilities incinerate non-recyclable materials at high temperatures, using the resulting heat to produce steam that drives turbines and generates electricity. For more insights, you can explore waste management best practices.

Advanced recovery technologies include anaerobic digestion, which breaks down organic waste to produce biogas and nutrient-rich digestate. Gasification and pyrolysis represent emerging thermal recovery methods that convert waste into synthesis gas or bio-oil under oxygen-limited conditions, potentially offering higher efficiency than traditional incineration.

While recovery doesn't maintain materials in their original form, it captures some value from waste that would otherwise be lost to landfill. When implemented with proper emissions controls, these technologies can provide both waste management solutions and renewable energy generation.

Disposal: Last Resort Options

Disposal sits at the bottom of the waste hierarchy, representing the least environmentally favourable option. Modern landfills are engineered containment systems designed to isolate waste from the surrounding environment, with features including bottom liners, leachate collection systems, and gas management infrastructure. For more insights on waste management practices, you can refer to this guide on best practices.

While necessary for some waste streams, disposal should be reserved for materials that cannot be managed through higher hierarchy options. Many jurisdictions now ban certain materials from landfills, including yard waste, electronics, and recyclables, to encourage more sustainable management practices.

The environmental impacts of disposal include greenhouse gas emissions (primarily methane from decomposing organic waste), potential groundwater contamination, and the permanent loss of potentially valuable resources. These impacts, combined with increasing landfill costs and decreasing capacity, make disposal reduction a priority for most waste management programs.

7 Best Practices for Commercial Waste Management

Implementing comprehensive waste management in business settings requires systematic approaches that address the full spectrum of waste-related challenges. Organizations that adopt these best practices typically see significant improvements in both environmental performance and operational costs, with waste disposal cost reductions often exceeding 30% when all elements are properly implemented.

1. Conduct a Waste Audit

A waste audit provides critical baseline data by systematically analyzing what's in your waste stream. This process involves collecting, sorting, and weighing waste to determine its composition, identifying opportunities for reduction, reuse, and recycling. Effective audits examine waste from all operational areas and may be conducted seasonally to account for variations in waste generation. Understanding what happens to rubbish in landfill can also provide insights into waste management practices.

During the audit, waste is typically categorized by material type (paper, plastic, metal, organics, etc.) and source (department or activity). This granular information reveals which waste streams offer the greatest opportunity for improvement and helps identify the root causes of waste generation. For example, an office audit might reveal excessive paper waste from a particular department, leading to targeted digitization efforts. For more on effective waste management, explore various waste separation methods.

While comprehensive audits may require external expertise, even simple self-performed audits can yield valuable insights. The key is to approach the process systematically and use the results to inform specific, actionable waste reduction strategies tailored to your organisation's unique waste profile.

2. Set Clear Reduction Targets

Effective waste management programs establish specific, measurable, achievable, relevant, and time-bound (SMART) goals. Rather than vague commitments to “reduce waste,” successful organizations set concrete targets like “decrease landfill waste by 25% within 18 months” or “achieve 90% recycling rate for packaging materials by year-end.”

Target-setting should be informed by your waste audit results, industry benchmarks, and organizational capabilities. While ambitious goals drive progress, they must remain achievable to maintain momentum and stakeholder buy-in. Consider establishing both short-term targets for immediate wins and longer-term goals that may require more substantial operational changes, such as implementing effective waste separation methods.

Once established, these targets should be communicated throughout the organization and incorporated into regular performance reporting. Celebrating milestones and progress helps maintain engagement and demonstrates the organization's commitment to continuous improvement in waste management.

3. Implement Proper Segregation Systems

Effective waste segregation forms the foundation of successful recycling and recovery efforts. The key is making proper disposal as convenient as possible through strategically placed, clearly labeled collection stations. Each station should include appropriate containers for all relevant waste streams, with consistent color-coding and signage across all locations.

The specific waste streams collected will depend on your waste profile and local recycling infrastructure. Common categories include mixed recycling, paper, cardboard, organics, glass, and landfill waste. For specialized waste streams like batteries, electronics, or confidential documents, central collection points may be more appropriate than distributed stations.

Visual cues significantly improve segregation accuracy. Consider incorporating photographs or actual examples of acceptable items on signage, especially for streams with complex acceptance criteria. Regular monitoring and feedback on segregation quality helps identify and address confusion or compliance issues before they contaminate large volumes of potentially recyclable materials.

4. Train All Staff on Protocols

Even the best-designed waste management system will fail without proper training and engagement. Comprehensive training should reach all staff members, from executives to frontline workers, with content tailored to each group's specific role in waste management. Initial training introduces key concepts and procedures, while regular refresher sessions address common mistakes and communicate program updates.

Effective training goes beyond simply instructing staff on where to put waste. It should explain the “why” behind waste management procedures, connecting individual actions to broader environmental and business benefits. This context helps build a culture where proper waste handling becomes second nature rather than an imposed burden.

Consider designating waste champions within different departments or areas to provide peer-to-peer guidance and feedback. These individuals serve as resources for questions, monitor compliance, and help identify improvement opportunities. Their visibility and accessibility reinforce the importance of waste management throughout daily operations.

5. Partner with Certified Waste Handlers

Selecting the right waste management service providers is crucial for ensuring that materials are handled responsibly after leaving your facility. Reputable partners should hold relevant certifications, maintain transparent tracking systems, and provide detailed reporting on the final destination of all collected materials. Don't hesitate to request facility tours or processing documentation to verify their claims.

The lowest-cost provider isn't always the best choice, especially if they achieve those savings through questionable disposal practices. Evaluate potential partners based on their environmental credentials, service reliability, reporting capabilities, and willingness to collaborate on waste reduction initiatives. The right partner will function as an extension of your sustainability team, providing expertise and innovative solutions.

Regular communication with your waste handlers helps identify new recycling opportunities, address contamination issues, and optimize collection schedules. Many providers offer waste minimization consulting as a value-added service, leveraging their industry expertise to help customers reduce disposal volumes and costs.

6. Track and Measure Performance

Systematic performance tracking transforms waste management from a reactive function to a data-driven improvement process. Effective tracking systems capture key metrics like total waste generated, diversion rates, contamination levels, and disposal costs across all waste streams and operational areas. This data provides the foundation for identifying trends, evaluating initiative effectiveness, and demonstrating ROI.

Modern tracking options range from simple spreadsheets to sophisticated waste management software that integrates with hauler reporting and internal systems. Whatever approach you choose, consistency is key—use standardized measurement units and data collection procedures to ensure meaningful comparisons over time. Visual management tools like dashboards help communicate performance to stakeholders and highlight areas needing attention.

Beyond regulatory compliance, comprehensive waste data supports various business objectives, from sustainability reporting to operational efficiency improvements. As the saying goes, “what gets measured gets managed”—and systematic waste tracking creates accountability that drives continuous improvement throughout your organization. For example, exploring e-waste recycling solutions can significantly enhance your sustainability efforts.

7. Continuously Improve Your Program

Effective waste management is an ongoing journey rather than a destination. The most successful programs embrace continuous improvement methodologies, regularly evaluating performance against targets and implementing refinements based on data and feedback. This cyclical approach—plan, implement, measure, improve—keeps your program responsive to changing waste streams, technologies, and regulatory requirements.

Regular program reviews should examine both quantitative metrics and qualitative factors like user satisfaction and operational impacts. Engage frontline staff in improvement discussions, as they often have valuable insights into practical challenges and potential solutions. External benchmarking can also identify industry best practices that might be adapted to your context.

As your program matures, consider expanding its scope to address upstream waste prevention opportunities throughout your value chain. Collaborating with suppliers on packaging reduction, designing products for recyclability, and implementing circular business models represent the next frontier in waste management excellence.

| Improvement Phase | Focus Areas | Typical Results |

|---|---|---|

| Initial Implementation | Basic segregation, staff training, measurement systems | 15-25% waste reduction, 40-50% diversion rate |

| Program Optimization | Refined sorting, targeted reduction initiatives, vendor partnerships | 25-40% waste reduction, 60-75% diversion rate |

| Transformation | Circular processes, supply chain integration, zero waste approaches | 40-90% waste reduction, 80-95% diversion rate |

Residential Waste Management Strategies That Work

While commercial waste management often receives more attention, households collectively generate enormous waste volumes that significantly impact environmental quality. Effective residential strategies apply the same waste hierarchy principles as commercial approaches but adapted to home settings where individuals have direct control over purchasing, usage, and disposal decisions.

Smart Purchasing Decisions

Waste prevention begins at the point of purchase. Thoughtful buying habits can dramatically reduce the amount of waste entering your home in the first place. Consider durability and repairability when selecting products, prioritizing quality items that won't quickly end up in the trash. Evaluate whether you really need an item before purchasing, and explore rental or borrowing options for occasionally-used products.

Packaging represents a major component of household waste. Look for products with minimal packaging, buy concentrates rather than diluted products, and choose refillable options when available. Bringing your own containers for bulk purchases eliminates packaging waste entirely for many food and household items. Shopping with reusable bags has become standard practice, but extending this principle to produce bags and other packaging further reduces waste.

Home Composting Systems

Food scraps and yard waste typically comprise 20-30% of household waste, yet these organic materials can easily be transformed into valuable compost through home composting systems. Options range from simple outdoor compost piles to sophisticated enclosed systems designed for apartment living. For households unable to compost directly, many communities now offer curbside organic waste collection or community composting sites.

Effective Recycling Habits

Residential recycling success depends on understanding your local program's specific requirements, which vary significantly between communities. Most recycling facilities provide detailed guidelines about accepted materials, preparation requirements (like rinsing containers), and collection procedures. Keeping these guidelines visible near your recycling stations helps ensure proper sorting and reduces contamination that can undermine the entire recycling process. For more information on best practices, check out this waste management guide.

Beyond curbside recycling, many communities offer specialised collection options for materials like electronics, batteries, paint, and household hazardous waste. Creating a designated area for storing these items until they can be properly disposed of prevents them from contaminating regular waste streams or causing environmental harm. Some retailers also accept specific products for recycling, including plastic bags (grocery stores), electronics (electronics retailers), and printer cartridges (office supply stores).

Hazardous Waste Handling

- Never dispose of chemicals, paints, batteries, or electronics in regular trash or recycling

- Store hazardous materials in original containers with labels intact

- Use community hazardous waste collection events or permanent drop-off facilities

- Consider less-toxic alternatives for household cleaning and maintenance

- Completely use products before purchasing replacements to minimise disposal needs

Improper disposal of hazardous waste poses serious environmental and public health risks, potentially contaminating soil and water supplies. Even small amounts of these materials can have outsized impacts—a single battery can contaminate 20 square feet of landfill space, while one gallon of motor oil can pollute a million gallons of drinking water. Learn more about what happens to rubbish in landfill and its decomposition process.

Most communities host periodic household hazardous waste collection events or maintain permanent collection facilities. These services typically accept items like paints, solvents, pesticides, automotive fluids, and electronic waste for proper processing. Planning ahead for these collection opportunities prevents hazardous materials from accumulating in your home while ensuring they're handled responsibly.

Prevention remains the best approach to hazardous waste. Evaluate whether less toxic alternatives might serve your needs, purchase only quantities you'll actually use, and properly maintain products to extend their useful life. Many traditional household chemicals can be replaced with environmentally preferable options that perform effectively while generating less hazardous waste.

For unavoidable hazardous products, proper storage in original containers prevents accidents and maintains label information for eventual disposal. Keep these materials away from children, pets, and heat sources, preferably in locked cabinets or storage areas. This careful handling protects both your household and the waste management workers who may eventually process these materials.

Waste Management Technologies Transforming the Industry

The waste management industry is undergoing a technological revolution that's enhancing efficiency while reducing environmental impacts. From collection to processing, new technologies are addressing longstanding challenges and creating opportunities for more sustainable waste handling. These innovations range from simple equipment improvements to sophisticated digital systems that optimize entire waste management networks.

Digital technologies are playing an increasingly important role in modern waste management. Internet of Things (IoT) sensors monitor fill levels in waste containers, optimising collection routes and reducing unnecessary pickups. Artificial intelligence systems improve sorting accuracy at material recovery facilities, identifying recyclables with greater precision than manual sorting alone. Blockchain applications are emerging to track waste materials throughout their lifecycle, enhancing transparency and accountability.

Equipment innovations are equally important in advancing waste management capabilities. High-efficiency balers reduce transportation costs by compacting recyclables, while optical sorting systems use spectrometry to identify and separate different plastic types. Contamination detection technologies help maintain recycling quality by identifying and removing problematic materials before they compromise entire batches.

Smart Bins and IoT Solutions

Smart waste bins equipped with sensors now monitor fill levels, detect contamination, and even compact waste to increase capacity. These systems transmit real-time data to waste management teams, enabling dynamic collection scheduling that services bins only when necessary. The result is more efficient routing, reduced collection frequency, and lower fuel consumption and emissions from collection vehicles.

Beyond operational efficiency, smart bin data provides valuable insights into waste generation patterns across locations and time periods. This information helps organizations identify unusual waste volumes that might indicate process problems or opportunities for targeted reduction initiatives. Some systems even provide direct feedback to users about contamination or improper sorting, creating an immediate learning opportunity.

While implementation costs have historically limited smart bin deployment, falling sensor prices and proven ROI are accelerating adoption. Many municipalities now incorporate these technologies into public waste infrastructure, while businesses increasingly view them as essential components of modern facility management systems. The integration of solar power has further expanded deployment options by eliminating the need for external power connections.

Advanced Sorting Systems

Material recovery facilities (MRFs) have traditionally relied heavily on manual sorting, but advanced automation is transforming these operations. Modern facilities combine mechanical, optical, and AI-powered systems to identify and separate materials with unprecedented speed and accuracy. These technologies are particularly valuable for processing single-stream recycling, where multiple material types arrive mixed together.

Optical sorters use near-infrared technology to identify different plastic polymers, allowing for more precise separation than is possible with manual sorting. Ballistic separators divide materials based on density and shape characteristics, while eddy current separators extract non-ferrous metals like aluminium from mixed streams. These mechanical systems work in concert with AI-powered robotic sorters that can learn to recognise and pick specific items from conveyor belts. For more on waste processing innovations, explore what is depackaging and its impact on recycling efficiency.

The benefits of advanced sorting extend beyond operational efficiency. By achieving higher purity levels in recovered materials, these technologies produce higher-value recyclables that command better market prices. This improved economics strengthens the entire recycling system while ensuring that more materials actually complete the recycling loop instead of being downgraded or discarded due to contamination.

Waste-to-Energy Conversion

- Thermal conversion processes that transform non-recyclable waste into electricity, heat, or fuel

- Biological conversion methods like anaerobic digestion that produce biogas from organic waste

- Emerging technologies such as gasification and pyrolysis that offer higher efficiency than traditional incineration

- Combined heat and power systems that maximize energy recovery from waste processing

- Carbon capture capabilities that reduce greenhouse gas impacts from thermal processes

Modern waste-to-energy facilities bear little resemblance to the incinerators of decades past. Today's systems incorporate sophisticated emissions controls that remove particulates, acid gases, and other pollutants before they reach the atmosphere. Many facilities now capture heat as well as generate electricity, significantly improving overall energy efficiency. These combined heat and power systems can achieve energy recovery rates of 80% or higher, compared to 20-25% for electricity-only generation.

While thermal waste-to-energy has traditionally dominated the field, biological conversion technologies are gaining prominence, especially for organic waste streams. Anaerobic digestion creates biogas from food waste, agricultural residues, and biosolids, providing both renewable energy and nutrient-rich digestate that can be used as fertiliser. This approach offers particular advantages for wet organic wastes that would require substantial energy inputs for thermal processing.

Biological Treatment Methods

Biological waste treatment harnesses natural decomposition processes to manage organic materials, which can comprise up to 30% of municipal waste streams. These approaches divert organics from landfills, where they would generate methane, a potent greenhouse gas. Instead, they transform these materials into valuable soil amendments that restore carbon and nutrients to agricultural and landscaping applications.

Composting technologies range from simple windrow systems to sophisticated in-vessel operations that precisely control temperature, moisture, and aeration. These controlled conditions accelerate decomposition while killing pathogens and weed seeds, producing stable compost within weeks rather than months. Emerging technologies like insect farming use black soldier fly larvae to process food waste, generating both protein-rich animal feed and organic fertiliser as outputs.

The growing recognition of soil health's importance in carbon sequestration and agricultural productivity has elevated the significance of biological waste treatment. By returning organic matter to soils, these approaches close nutrient cycles and help build carbon reservoirs that mitigate climate change. This perspective transforms organic “waste” into a valuable resource for environmental restoration and sustainable food production.

Common Waste Management Challenges and Solutions

Despite advances in waste management technologies and practices, significant challenges remain in implementing effective systems. Understanding these challenges—and their potential solutions—is essential for anyone working to improve waste management outcomes. While the specific barriers vary between settings, several common themes emerge across different contexts.

Contamination Issues

Contamination—the inclusion of inappropriate items in recycling or composting streams—remains one of the most persistent challenges in waste management. Even small amounts of contamination can compromise entire batches of recyclables or compost, reducing their value or rendering them completely unprocessable. Common contaminants include food residue in recyclables, non-compostable plastics in organic waste, and hazardous materials in regular trash.

Addressing contamination requires a multi-faceted approach combining clear guidelines, consistent education, appropriate infrastructure, and regular feedback. Visual signage with specific examples of acceptable and unacceptable items helps users make correct disposal decisions in the moment. Strategic bin placement and design can reduce confusion and make proper sorting more convenient than improper disposal. Regular waste audits identify persistent contamination sources, enabling targeted interventions before small problems become systemic issues. For more insights, consider exploring waste management best practices.

Collection Logistics

Waste collection represents one of the most visible and resource-intensive aspects of waste management, particularly in densely populated urban areas or sprawling rural regions. Inefficient collection routes waste fuel, increase emissions, and drive up service costs. Vehicle limitations may restrict service in certain areas, while seasonal or special event waste surges can overwhelm normal collection capacity.

Modern route optimisation software addresses many of these challenges by analysing collection data to identify the most efficient pathways and schedules. These systems incorporate variables like traffic patterns, vehicle capacity, and waste generation rates to minimise time and fuel consumption. Alternative collection models like centralised drop-off points or hub-and-spoke systems can provide service in challenging locations where door-to-door collection isn't feasible or cost-effective.

Collection vehicle innovations are also transforming this aspect of waste management. Electric and compressed natural gas vehicles reduce emissions and noise, while multi-compartment trucks enable single-pass collection of multiple waste streams. Specialised vehicles designed for specific environments—like narrow alleyways or rural roads—ensure that collection services can reach all waste generators regardless of location constraints.

Processing Capacity Limitations

Many regions face significant gaps between their waste diversion goals and the actual infrastructure available to process recyclables, organics, and other recoverable materials. This capacity shortfall becomes particularly acute when waste volumes increase or international markets for recyclables tighten their acceptance criteria. Without sufficient domestic processing capacity, even well-sorted recyclables may ultimately be landfilled.

Addressing these limitations requires coordinated investment in processing infrastructure across both public and private sectors. Long-term municipal contracts can provide the revenue certainty needed for private companies to finance new facilities, while public-private partnerships may enable projects too large for either sector to undertake alone. Regional cooperation allows neighbouring communities to achieve the economies of scale necessary for advanced processing technologies that would be unaffordable for individual municipalities.

Beyond physical infrastructure, developing robust local markets for recovered materials is equally important for long-term system stability. When recycled materials and compost products can be used locally, transportation costs decrease, and the entire recovery system becomes more resilient to international market fluctuations. Economic development initiatives that attract manufacturers using recycled feedstocks create this market pull while simultaneously generating local jobs.

Public Education Gaps

Even the most sophisticated waste management system will fail without informed participation from waste generators. Unfortunately, many people remain confused about proper waste handling practices or are unaware of available services. This knowledge gap leads to contamination, missed recycling opportunities, and improper disposal of hazardous materials. The challenge is particularly acute in areas with transient populations or multiple languages, where maintaining a consistent understanding becomes even more difficult.

Effective education strategies combine clear, actionable information with motivation that connects waste behaviours to values people already hold. Simple, visual communications that show exactly what goes where help overcome language barriers and attention limitations. Community-based social marketing techniques identify and address specific barriers to proper waste management behaviours, rather than simply providing information. Targeted outreach to key influencers—like property managers, community leaders, and teachers—leverages existing social networks to amplify messages and normalise positive waste behaviours.

Creating a Waste Management Plan: Step-by-Step Guide

A comprehensive waste management plan provides the roadmap for translating waste management principles into practical action. Whether for a household, business, or community, a well-designed plan establishes clear priorities, assigns responsibilities, and creates accountability for results. The planning process itself often reveals improvement opportunities that might otherwise remain hidden in day-to-day operations.

1. Assess Current Waste Streams

- Collect data on waste volumes, composition, and current handling methods

- Identify seasonal variations and unusual waste generators

- Map waste flows from generation through final disposal

- Calculate current diversion rates and disposal costs

- Benchmark performance against similar organisations or communities

This assessment phase establishes your baseline, revealing both what you're doing well and where opportunities exist for improvement. For businesses, examine purchasing records alongside waste data to connect upstream decisions with downstream waste impacts. For communities, analyze different sectors (residential, commercial, institutional) separately to identify targeted intervention opportunities. In all cases, document current service providers, contract terms, and disposal facilities to understand your existing waste management network.

While comprehensive data is ideal, don't let perfect be the enemy of good. Even estimated or sample-based information provides a starting point for planning and can be refined as your program develops. Visual waste audits—physically examining and categorising representative waste samples—often reveal surprising insights that wouldn't be apparent from invoices or haulier reports alone.

Beyond quantitative data, assess qualitative factors like staff knowledge, user satisfaction with current systems, and operational pain points. Interviews with key stakeholders—from maintenance staff to department managers—can reveal practical barriers to improved waste management that might not be visible in the numbers alone. For instance, understanding waste separation methods can be crucial in identifying these barriers and implementing effective solutions.

2. Identify Improvement Opportunities

With baseline data in hand, the next step is identifying specific opportunities for improvement. Prioritise these opportunities based on their potential impact, implementation difficulty, and alignment with organisational goals. Quick wins—high-impact changes with minimal implementation barriers—provide momentum for longer-term initiatives. Typical opportunity areas include recycling program expansion, organic waste diversion, packaging reduction, and process modifications that minimise waste generation.

3. Set Specific, Measurable Goals

Translate improvement opportunities into concrete goals with specific metrics and timeframes. Rather than vague commitments to “increase recycling,” set targets like “achieve 60% diversion rate by 2023” or “reduce contamination in recyclables to below 8% within 12 months.” These SMART goals (Specific, Measurable, Achievable, Relevant, Time-bound) create clarity about expectations and enable meaningful progress tracking. Consider both short-term targets that maintain momentum and longer-term goals that drive systemic change.

4. Select Appropriate Methods and Technologies

- Choose collection systems and containers appropriate for your space and waste volumes

- Identify processing partners with capacity for your specific waste streams

- Select education and communication methods tailored to your audience

- Consider monitoring technologies that provide data for ongoing improvement

- Evaluate cost implications and ROI for all selected approaches

The methods and technologies you select should align with your specific context and goals. A manufacturing facility generating large volumes of homogeneous materials will need different solutions than an office producing primarily paper and packaging waste. Consider space constraints, aesthetic requirements, and user convenience alongside technical performance when selecting collection equipment. Remember that the most sophisticated technology won't succeed if it doesn't fit your operational reality.

Vendor selection represents a critical decision point in this phase. Beyond basic service capabilities, evaluate potential partners based on their reporting systems, contamination management approaches, and commitment to environmental outcomes. Request processing facility tours and ask detailed questions about where materials actually go after collection. The right partners will welcome this due diligence and demonstrate transparency about their operations.

Balance innovation with proven effectiveness when selecting methods and technologies. While cutting-edge approaches may offer performance advantages, they also carry implementation risks. Consider pilot testing new methods before full-scale deployment, and plan for contingencies if technologies don't perform as expected. A phased implementation approach often proves more successful than attempting to transform everything simultaneously. For more information on best practices, you can explore this guide on waste management best practices.

5. Implement and Monitor Your Plan

Implementation should follow a structured timeline with clear responsibilities and regular progress reviews. Launch new initiatives with appropriate communication and training to ensure all participants understand the changes and their rationale. Monitor key performance indicators regularly, addressing problems promptly before they undermine program credibility. Celebrate successes to maintain momentum and demonstrate organisational commitment to waste management improvements.

Build continuous improvement mechanisms into your plan from the beginning. Regular waste audits verify that actual results match reported performance, while user feedback identifies operational issues that might otherwise go unnoticed. Use this information to refine your approach, adapting to changing conditions and incorporating lessons learned. The most successful waste management programs evolve over time, becoming increasingly effective as they mature.

The Future of Waste Management: Circular Economy Approaches

The future of waste management lies in moving beyond traditional linear models toward truly circular approaches that eliminate the concept of waste entirely. This paradigm shift recognises that today's waste represents a design failure—materials that could remain valuable resources are instead losing their utility. Circular economy principles address this failure by designing products and systems that maintain material value through multiple lifecycles. For instance, effective waste separation methods are crucial in ensuring that materials can be reused and recycled efficiently.

Product design plays a central role in this transition. Designing for durability, repairability, and eventual recyclability ensures that products remain useful for as long as possible and can be readily recovered at end-of-life. Modular designs allow for component replacement rather than whole-product disposal, while standardised materials simplify eventual recycling. These approaches require collaboration across entire value chains, with designers, manufacturers, retailers, consumers, and waste managers all playing essential roles.

New business models are emerging to support circular material flows. Product-as-a-service arrangements, where manufacturers retain ownership of physical goods while customers purchase the service they provide, create incentives for durability and material recovery. Sharing platforms increase utilisation rates for underused assets, reducing the resources needed to deliver their benefits. Repair and refurbishment businesses extend product lifespans while creating local jobs that cannot be outsourced.

- Design for disassembly ensures products can be easily separated into component materials

- Chemical recycling technologies break plastics down to molecular building blocks

- Digital material passports track embedded resources throughout product lifecycles

- Industrial symbiosis networks transform one company's waste into another's raw material

- Biomimicry principles inspire waste-free production systems modelled on natural ecosystems

Frequently Asked Questions

As waste management practices evolve, many people have questions about best practices, environmental impacts, and practical implementation details. These frequently asked questions address common concerns and provide actionable guidance for improving waste management in various contexts.

How much waste does the average person produce annually?

The average American generates approximately 4.9 pounds of municipal solid waste per day, totaling about 1,790 pounds annually. This figure varies significantly between countries, with developed nations typically producing more waste per capita than developing economies. However, waste composition differs substantially between regions, with high-income countries generating more packaging waste and lower-income areas producing higher proportions of organic waste. Individual waste generation can be reduced through mindful consumption, reuse practices, and home composting.

What types of waste are most harmful to the environment?

Hazardous wastes pose the most immediate environmental threats due to their toxicity, reactivity, flammability, or corrosivity. These materials—including batteries, electronics, paints, pesticides, and certain cleaning products—can contaminate soil and water supplies even in small quantities. Proper disposal through designated hazardous waste collection programs is essential for preventing environmental damage.

Plastic waste represents another significant environmental concern due to its persistence in the environment. Conventional plastics can take hundreds of years to break down, and even then, they merely fragment into microplastics rather than truly biodegrading. These microplastics have been found throughout the food chain and in remote environments worldwide. Particularly problematic are single-use plastics like bags, straws, and food packaging that provide brief utility before becoming long-term pollution. To understand how waste is managed, you can explore what happens to rubbish in landfill.

Electronic waste (e-waste) combines hazardous components with valuable recoverable materials, making proper management both environmentally critical and economically beneficial. Improper handling releases heavy metals and flame retardants into the environment, while appropriate recycling recovers precious metals and rare earth elements. The rapid pace of technological change has accelerated e-waste generation, with many devices becoming obsolete before their physical components wear out. For more information on waste management practices, you can explore this guide on waste management best practices.

Can all plastics be recycled?

Not all plastics can be recycled through conventional mechanical recycling systems. While plastics with resin identification codes #1 (PET) and #2 (HDPE) are widely accepted in most recycling programs, other types face various technical and economic barriers to recycling. Thermoset plastics that are cured into permanent shapes cannot be remelted, while many flexible films and multi-layer packaging are technically difficult to process. Small items like straws and bottle caps often fall through sorting equipment, while black plastics cannot be detected by optical sorters used in many facilities.

- PET (#1) and HDPE (#2): Widely recycled with established markets

- PVC (#3): Rarely recycled due to chlorine content and limited markets

- LDPE (#4): Sometimes recycled, primarily through store drop-off programs

- PP (#5): Increasingly recycled as technology and markets develop

- PS (#6): Limited recycling availability in most regions

- Other (#7): Mixed or specialised plastics with limited recycling options

Even for technically recyclable plastics, market conditions significantly impact whether recycling actually occurs. Virgin plastic prices, influenced by oil prices and production capacity, determine whether recycled materials are economically competitive. When virgin prices fall, recyclers may struggle to sell their output, potentially leading to stockpiling or disposal of collected recyclables. These market dynamics highlight why waste reduction and reuse should be prioritised over recycling whenever possible.

Emerging chemical recycling technologies may eventually expand plastic recyclability by breaking polymers down to their chemical building blocks. These processes could potentially handle mixed or contaminated plastics that challenge conventional mechanical recycling. However, these approaches remain primarily in development stages, with questions about energy requirements, economics, and environmental impacts still being addressed.

What's the difference between landfill and incineration?

Landfills and incineration represent different approaches to managing residual waste that cannot be recycled or composted. Landfills isolate waste from the environment using engineered containment systems, while incineration reduces waste volume through combustion, often with energy recovery. Modern landfills feature multiple protective layers including clay and synthetic liners, leachate collection systems, and gas management infrastructure. These systems minimize environmental impacts but require ongoing monitoring and maintenance, potentially for decades after closure.

Incineration offers significant volume reduction—typically shrinking waste to about 10% of its original volume—and destroys pathogens and some hazardous compounds through high-temperature combustion. Modern facilities incorporate extensive emissions control systems that remove particulates, acid gases, and other pollutants before exhaust gases are released. When equipped with energy recovery systems, these facilities can generate electricity and/or heat, partially offsetting their operational energy requirements and potentially replacing fossil fuel consumption elsewhere in the energy system.

How can businesses save money through better waste management?

Improved waste management directly reduces disposal costs, which have increased significantly in many regions as landfill capacity diminishes and regulatory requirements tighten. Recycling often costs less than landfill disposal, especially for high-volume materials like cardboard and metal. Waste prevention delivers even greater savings by eliminating both purchasing and disposal costs for materials that would otherwise become waste. Right-sizing service levels based on actual waste generation can eliminate unnecessary pickups and container rentals.

Beyond direct waste management costs, improved practices often yield operational benefits throughout an organization. Streamlined packaging reduces both material costs and labor associated with unpacking and disposal. Process optimisation that minimises scrap or off-spec products improves yield rates and resource efficiency. In manufacturing settings, waste reduction typically correlates with overall process efficiency improvements that reduce energy consumption, water usage, and labour requirements.

Many businesses discover that waste management improvements enhance their market position and customer relationships. Consumers increasingly prefer environmentally responsible companies, while B2B customers may include waste management practices in supplier evaluation criteria. Some industries face specific customer requirements regarding packaging recyclability or take-back programs. Proactively addressing these expectations can preserve market access and potentially command premium pricing for environmentally preferable products and services.

Perhaps most importantly, waste reduction initiatives often reveal broader business insights that drive innovation and continuous improvement. The systematic examination of waste streams frequently identifies process inefficiencies, quality issues, or communication breakdowns that affect multiple aspects of operations. Addressing these root causes delivers benefits far beyond waste management, creating a positive return on investment that makes waste reduction among the most financially attractive sustainability initiatives.

For expert guidance on implementing waste management best practices tailored to your specific needs, WasteWise offers comprehensive consulting services that turn waste challenges into environmental and economic opportunities. Additionally, learn about waste-to-energy companies that can help transform waste into valuable resources.