Metal detectors in recycling use transmitter-receiver coils to create a constant electromagnetic field that detects all metal types (ferrous, non-ferrous, and stainless steel) by sensing disturbances in that field. Find out how, when contaminants pass through, they alter the magnetic flux, triggering an automated rejection mechanism—such as air jets or pushers—to divert the material.

How Metal Detectors Work in Recycling – Key Points

- Metal contamination is responsible for at least $9 million in annual losses for the recycling industry due to equipment damage, downtime, and reduced material value.

- Today's metal detectors use electromagnetic fields to detect ferrous, non-ferrous, and stainless steel contaminants, with the ability to detect contaminants as small as 0.3mm under ideal conditions.

- By strategically placing metal detectors at pre-shredder, post-sort, and final quality control points, the amount of contamination removed and equipment protection is maximized.

- When properly implemented, metal detection systems can provide a return on investment within 6-18 months by preventing damage and producing higher-quality recycled materials.

- Next-generation metal detection systems enhanced with AI can reduce false positives by up to 35% while improving detection accuracy.

A small piece of metal that finds its way into a plastic recycling grinder can cause a disaster. A single metal fragment that goes undetected can result in tens of thousands of dollars in equipment damage, production downtime, and reduced product quality. That's where metal detection systems come in, serving as the unsung heroes of recycling operations.

Metal detectors are like the unsung heroes of recycling facilities, working non-stop to detect and remove any metal contamination before it can cause any damage. Industrial metal detectors have come a long way from their early versions, now using advanced electromagnetic technology to find even the smallest metal pieces hidden in recyclable materials.

Quick Overview

One of the biggest hurdles in modern recycling operations is metal contamination. It can cause everything from damage to machinery to problems with the quality of the product, and it can put both profits and sustainability targets at risk.

This guide will explain how metal detection technology operates, the different systems that are used in recycling facilities, and the real-world advantages that these systems bring to operations of all sizes.

If you're in charge of a city recycling plant, a dedicated plastic recycling center, or any other type of recycling facility, it's important to understand how metal detectors work. This knowledge can help you improve your facility's contamination control processes. In this article, we'll cover everything from the basics of metal detection to advanced strategies for using this technology.

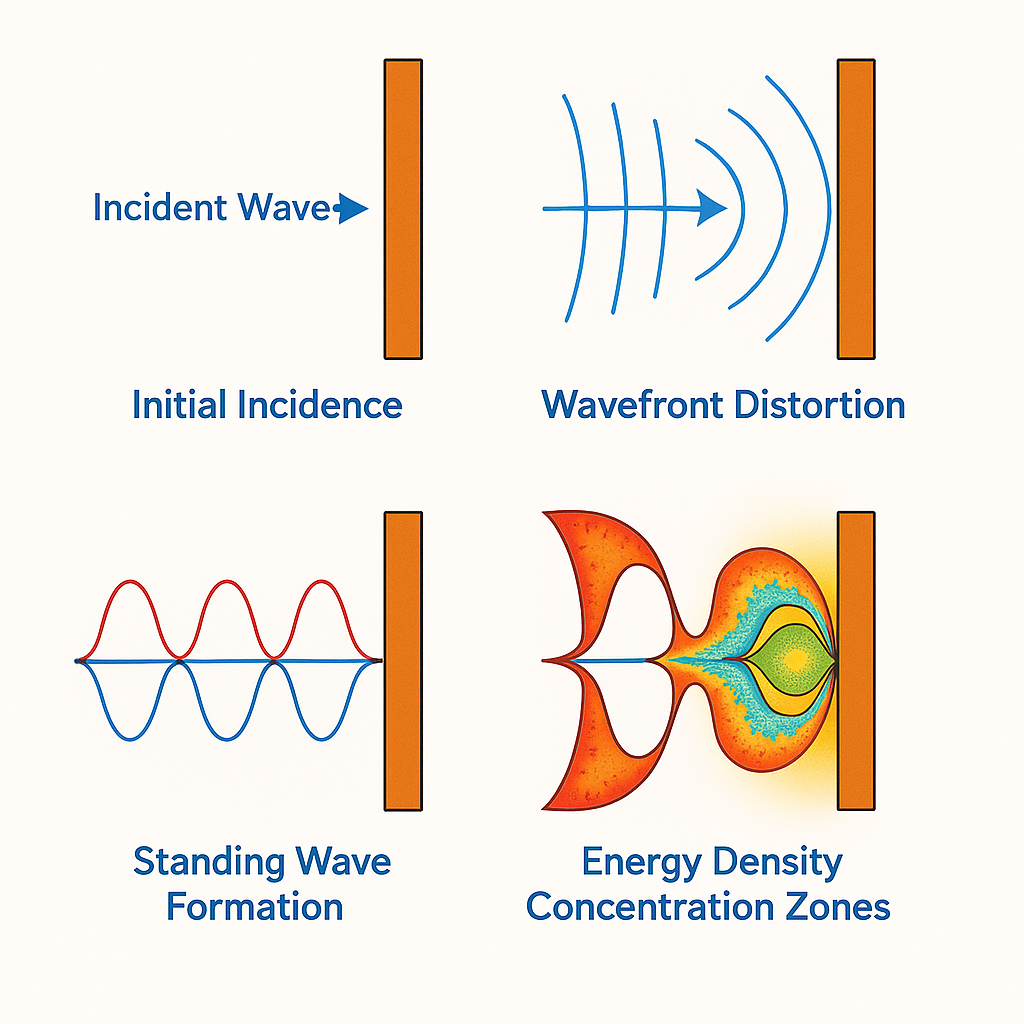

“Metallic Objects and Electromagnetism …” from www.elexana.com and used to explain how metal detectors work in recycling with no modifications.

Recycling's $9 Million Metal Contamination Problem

Every year, the worldwide recycling industry spends about $9 million to repair equipment damaged by metal contamination. That's just the cost of the equipment. When you add in the downtime, the problems with quality, and the reduction in the value of the materials, the total cost is closer to $25 million.

A single piece of metal that isn't detected can damage a key part of a machine. Replacing parts for industrial shredders can cost between $5,000 and $30,000 each. That doesn't include the cost of labor to install the part and the lost production while the machine is being repaired.

How Metal Detectors Work in the Recycling Industry

The use of metal detectors in recycling is based on the principles of electromagnetism, which have been perfected over years of industrial use. Today's systems do more than just detect the presence of metal – they can distinguish between different types of metal, determine the size of the contamination, and make decisions in the blink of an eye to protect the processes that follow. This level of precision has turned contamination control from a reactive measure to repair damage into a proactive strategy to ensure quality.

How Electromagnetic Fields Help Identify Metals

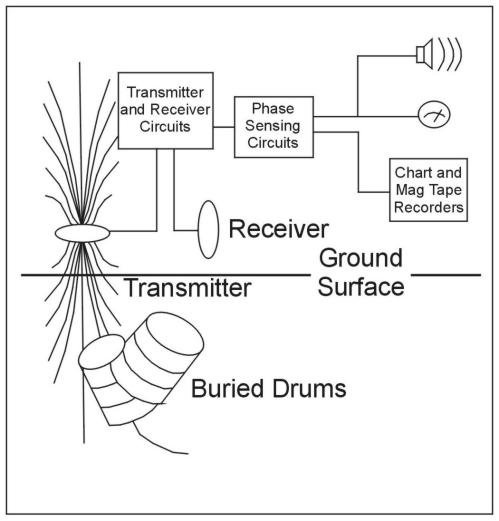

“Metal Detectors …” from www.epa.gov and used with no modifications.

Industrial metal detectors work by creating an electromagnetic field. When a metal object passes through this field, it disrupts the electromagnetic pattern. This disruption is then detected and analyzed by sensors. The size and nature of the disruption will depend on the type of metal, which means that modern systems can tell the difference between ferrous metals (those that contain iron), non-ferrous metals (like aluminum or copper), and stainless steel, which is typically hard to detect.

These devices use transmitter coils to create an electromagnetic field and receiver coils to spot any changes in the field when metal is present. The more sophisticated systems use several coils arranged in various directions to establish a three-dimensional detection zone. This reduces the blind spots that could let contaminants slip through undetected. This multi-directional approach is especially important in recycling applications where materials are flowing in unpredictable directions and densities.

How Different Types of Metals are Detected

- Ferrous metals (iron, steel): These are the easiest to detect because of their magnetic properties, and are typically detectable down to 0.5mm diameter

- Non-ferrous metals (aluminum, copper, brass): These are moderately detectable, typically identified down to 0.8-1.2mm diameter

- Stainless steel (300 series): This is the most challenging to detect, typically requiring fragments of 1.5mm diameter or larger

- Composite or partially metallic materials: These have variable detection rates, often requiring specialized calibration

- Wire fragments: Detection of these varies based on orientation, with perpendicular wires being easier to detect than parallel ones

The sensitivity of detection is not only determined by the detection technology. It is significantly influenced by factors including material density, moisture content, product effect (electrical conductivity of the recyclable material itself), and the speed at which materials pass through the detection zone. High-quality systems now offer sensitivity enhancements that account for these variables, with some capable of detecting metallic particles as small as 0.3mm under ideal conditions.

Thanks to the forward march of technology, digital signal processing now enables an even more accurate detection process while also reducing the number of false positives that could halt production for no reason. For recycling operations, this increased accuracy directly leads to improved operational efficiency and product quality.

Interpreting Signals and Avoiding False Alarms

“False Rejects in Metal Detectors” from www.foodmanvision.com and used with no modifications.

Today's metal detectors use complex signal processing algorithms that can tell the difference between real metal contamination and what's known as the “product effect”—the natural electrical conductivity found in some recyclable materials. This ability to discriminate is essential in recycling settings where materials can differ significantly in terms of composition, moisture content, and density.

False alarms can be just as troublesome as undetected contaminants, leading to unwarranted production halts and material refusal. Modern detection systems now include adaptive learning features that memorize the electromagnetic fingerprints of ordinary materials, lowering false alarms by as much as 70% compared to older generation machinery. Some of the most advanced systems can even adjust for environmental conditions such as temperature changes and electromagnetic disturbance from nearby machinery.

Different Kinds of Metal Detectors Used in Recycling Plants

Recycling plants use a variety of metal detection technologies, each designed for specific types of materials and stages in the process. The choice of technology depends on things like the type of material, the speed of the conveyor belt, the required sensitivity of the detection, and the conditions of the environment. For those interested in broader sustainable practices, exploring sustainable waste management can provide valuable insights.

Underbelt Conveyor Metal Detectors

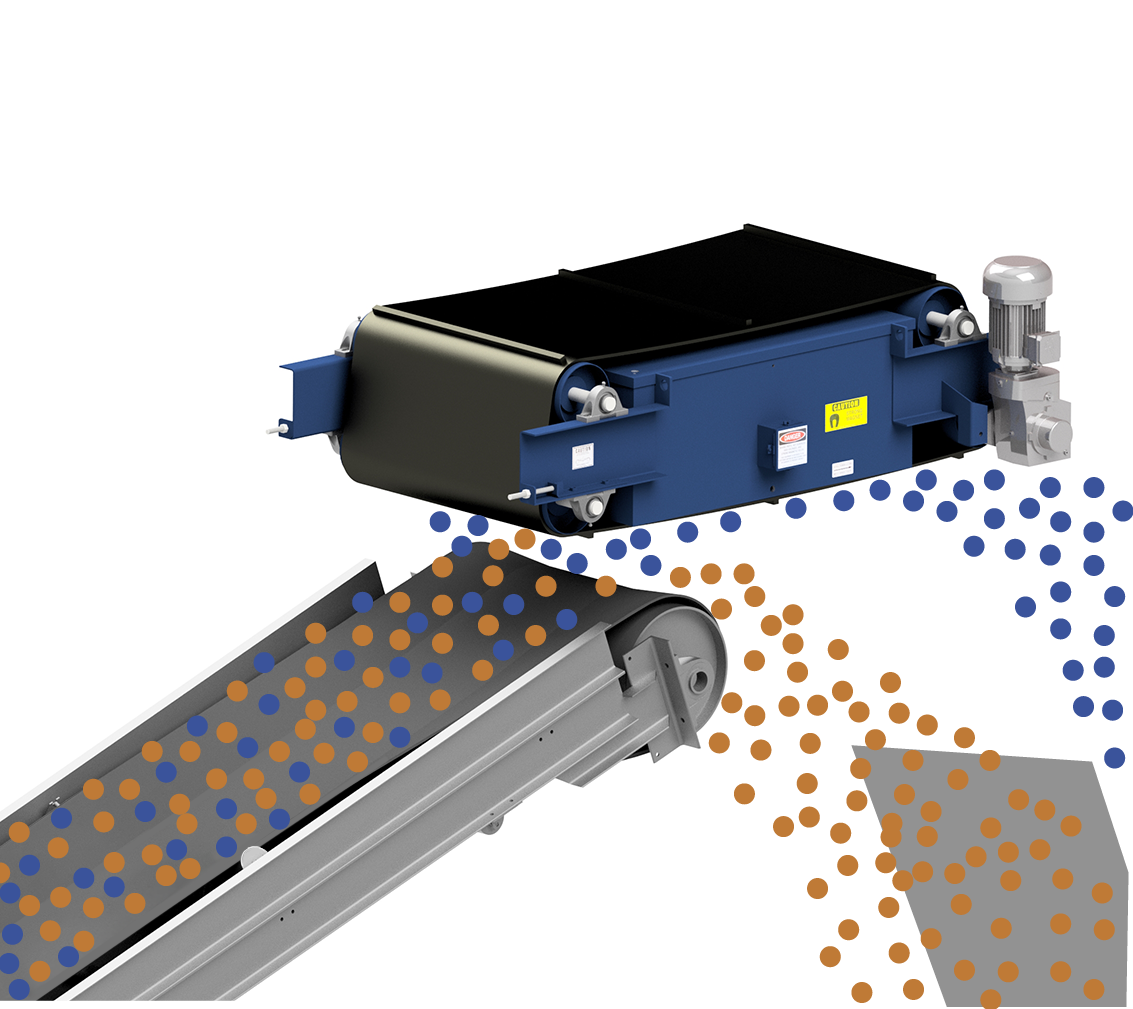

“Under Belt Metal Detectors for …” from buntingmagnetics.com and used with no modifications.

Underbelt detectors are the mainstay of recycling metal detection, placed under conveyor belts to examine materials as they pass above. These systems usually consist of a transmitter coil that creates an electromagnetic field and receiver coils that notice disruptions when metal passes through. Contemporary underbelt systems can identify both ferrous and non-ferrous metals, with high-end models providing sensitivities as low as sub-millimeter size under ideal conditions.

The main benefit of underbelt systems is that they can scan large quantities of material without interrupting the flow of the material. High-end models come with automatic belt speed monitoring and phase tracking to keep detection accuracy high, even if the production rate changes. Many facilities put these detectors right before important processing equipment such as grinders, shredders, or granulators to avoid expensive damage.

Hovering Magnetic Separators

“Overhead Magnetic Separator | Permanent …” How Metal Detectors Work that detect and remove tiny metal pieces from dingsmagnets.com and used with no modifications.

Although they are technically magnetic separators and not detectors, hovering magnetic separators are pivotal in removing iron contamination from recycling streams. These systems create strong magnetic fields that physically attract and elevate iron metals from conveyors, separating them from the flow of materials automatically. Contemporary models incorporate self-cleaning designs that automatically discharge captured metal into collection bins, minimizing the need for maintenance.

Overhead systems are especially good at taking out bigger ferrous items such as screws, nails, and fragments of sheet metal from bulky recycling streams. Many facilities use them as a first line of defense before more sensitive detection systems to deal with the larger contaminants that could overload precision detection equipment.

Tunnel-Style Detectors for Minuscule Pieces

“Small Magnetic Separation” from www.eriez.com and used with no modifications.

Tunnel-style metal detectors work by creating a completely enclosed detection area that materials move through, offering the ability to scan from every angle. This design is particularly good at finding tiny pieces of metal in free-falling streams of material or when dealing with granulated recyclables. The enclosed design also protects the detection components from environmental interference, which improves accuracy in difficult industrial settings.

Plastic recycling plants often place tunnel detectors after the first grinding stage but before the final extrusion or pelletizing. This is because even the tiniest bit of metal contamination can ruin dies or negatively affect the quality of the end product. Advanced tunnel systems have automatic rejection mechanisms. These divert contaminated material through fast-acting pneumatic or mechanical gates. This keeps the production flow going while only removing the affected parts.

Production Line Inline Metal Detectors

Inline detectors are designed to be directly integrated into pneumatic transport systems, processing pipes, or material drops, scanning materials as they flow through these contained pathways. These specialized systems are designed to overcome the challenge of detecting metal in densely packed or rapidly moving material streams where traditional conveyor-based detection might struggle. High-sensitivity inline detectors can identify contamination as small as 0.5mm in granulated plastic recyclate, ensuring the purity of high-value reclaimed materials.

Quality Control with Handheld Metal Detectors

“BARSKA Handheld Metal Detector BE12232 …” from www.homedepot.com and used with no modifications.

Handheld metal detectors are a great supplement to fixed detection systems. They offer the flexibility to do spot checks, troubleshoot, and verify suspected materials. Despite being portable, today's industrial handheld detectors have impressive sensitivity. They can pinpoint the location of contamination within bales or piles of material. Quality control teams often use these devices for final verification of high-value recycled materials before shipping. They also use them to investigate rejected batches to find the source of contamination.

Where to Put Metal Detectors for the Best Results

By putting metal detectors in key locations around a recycling facility, you can create a network that catches contamination before it becomes a problem. This helps to protect your equipment and ensure that the end product is of the highest quality. Instead of just having one detection point, the best facilities use a staged approach that catches different types of contamination at different points in the process.

Not only does this multi-level approach enhance the overall effectiveness of detection, but it also provides a safety net to prevent expensive contamination slip-ups. The best set-up depends on the layout of the facility, the types of materials being processed, and the vulnerability of the equipment, but there are a few key spots that have become common practice in the industry.

- Receiving/initial sorting: Early detection prevents contamination from entering the system

- Pre-processing: Protection for high-value equipment like shredders and grinders

- Post-processing: Quality verification before material enters refinement stages

- Final quality control: Last chance verification before product packaging or shipping

- Critical transfer points: Detection at conveyor transitions where material orientation changes

Detection sensitivity typically increases at each successive stage, with coarse detection at initial sorting giving way to high-precision scanning before final processing. This progressive approach balances operational efficiency with contamination control, focusing the most sensitive (and often slower) detection at points where material volume has been reduced and flow is more controlled.

Many facilities also include specialized detection points to deal with their unique contamination challenges. For example, facilities that process municipal recycling may include detection specifically for fragments of aluminum cans. Meanwhile, electronics recyclers might focus on detecting tiny fragments of copper wire that could contaminate plastic streams.

Assessing Return on Investment: The Financial Advantages of Metal Detection

For recycling facilities, metal detection systems are a substantial capital expenditure, with all-inclusive options varying from $15,000 for rudimentary systems to in excess of $100,000 for sophisticated multi-point detection networks. Nonetheless, when correctly utilized, these systems generally provide a return on investment in 6-18 months through various value streams that directly affect net income. Learn more about how conveyor belt metal detectors are utilized in the recycling industry.

Saving Money by Preventing Damage to Equipment

The most obvious benefit that comes to mind is the prevention of catastrophic damage to equipment. A single piece of metal that makes its way into a high-speed grinder can result in repairs that cost between $10,000 and $30,000. This doesn't even take into account the production time that is lost. For facilities that process more than 20 tons per day, downtime can cost between $1,500 and $3,000 per hour in direct operational losses.

Contemporary recycling machinery, such as twin-shaft shredders and fine grinding systems, have precision components with tight tolerances that are especially susceptible to metal contamination. The cost of replacement cutting blades for industrial plastic grinders usually ranges from $2,000 to $8,000 per set, with labor costs adding another $1,500 to $3,000 for installation. If the damage is more serious and affects drive systems or bearings, repair costs can skyrocket to between $25,000 and $50,000.

Aside from the immediate costs of fixing the equipment, the damage can cause a ripple effect of operational disruptions. Emergency maintenance pulls technical resources away from preventative work, causing a backlog in maintenance that can affect the overall reliability of the facility. Unplanned stoppages also cause a buildup of material that needs to be dealt with, sometimes requiring temporary storage or extra handling, which increases costs even more.

Case Study: A Recycler in the Pacific Northwest Saves $127,000 Every Year

A moderate-sized plastic recycling company in Washington state decided to install metal detection systems throughout their facility after suffering four major equipment breakdowns in a single year. After the systems were put in place, they documented a savings of $127,000 in the first year alone through reduced repair costs ($78,000), decreased downtime ($32,000), and lower maintenance labor expenses ($17,000). The system, which cost $89,000, paid for itself in just 8.4 months.

The Value of Improving Product Quality

While protecting equipment often drives the initial decision to invest, many facilities find that improving product quality delivers even greater long-term value. Metal contamination in finished recycled materials can significantly lower selling prices or make entire batches unsellable. Premium-grade recycled plastic flake or pellets typically sell for 15-30% higher prices than standard grades, with metal contamination being a main factor in determining quality.

It's not uncommon for facilities that have installed a full metal detection system to see an 8-12% increase in revenue related to quality. This is due to being able to access markets that are higher value and having fewer rejections from customers. Over time, these improvements in quality can add up. The facility can become known for always having clean materials. This can often lead to becoming a preferred supplier for manufacturers that need high-purity recycled inputs.

Lowering the Risk and Cost of Accidents

In recycling facilities, metal contamination is a major safety concern. Workers sorting materials by hand can be cut by sharp pieces of metal, and metal that is thrown out of processing machines can be a dangerous projectile. If a piece of equipment fails because of metal contamination, the sudden release of energy can cause serious accidents and injuries.

High-tech detection systems are the unsung heroes of the recycling industry, tirelessly removing harmful metal objects before they can cause any damage. This not only helps to keep workers safe but also has a positive impact on the bottom line, reducing workers' compensation costs, lowering insurance premiums, and decreasing liability exposure. On average, recycling facilities with state-of-the-art metal detection systems see a 15-30% reduction in workplace incidents. Some even report a 5-12% decrease in insurance premiums after implementing stringent contamination control measures.

Increased Profits from Material Sales

The financial aspect of recycled materials greatly favors pure, regular outputs. Recycled plastic that is free from contamination can demand premiums of $150-$400 per ton compared to contaminated alternatives, with the gap growing for specialized materials like food-grade recycled PET or engineered resins. Paper pulp that is free from metal also sells at significant premiums, especially for high-grade applications where metal contamination would harm production equipment or lower product quality.

Advanced metal detection and separation systems allow recyclers to consistently produce these high-grade outputs, reaching higher-value market segments that remain inaccessible to facilities with basic contamination control. Many operators have reported that access to these premium markets alone justifies their investments in metal detection, with some facilities recording 20-35% revenue increases per ton after implementing comprehensive detection systems that allow them to guarantee metal-free products to discerning customers. For those interested in broader sustainable practices, exploring sustainable waste management strategies can further enhance recycling operations.

What's Next for Metal Detection Tech in Recycling

With the latest advancements in metal detection technology, we can look forward to even better performance, thanks to the integration of artificial intelligence, improved sensor technology, and better connectivity. Metal detection systems that use AI can learn from false positives and missed contaminants, which allows them to continuously improve their detection accuracy without needing manual recalibration. These systems that optimize themselves usually have 25-35% better detection rates than traditional equipment, and they also reduce false positives by a similar margin.

Multi-sensor fusion is another emerging area, with advanced systems now combining electromagnetic detection with other sensing technologies such as X-ray, optical sorting, and near-infrared spectroscopy. These hybrid systems can detect metal contamination while also identifying plastic types, paper grades, or other material characteristics at the same time, creating comprehensive sorting solutions that address multiple quality parameters in one go. For recycling facilities that are facing increasingly strict output specifications, these multi-function systems offer compelling efficiency advantages and investment synergies.

Common Questions About How Metal Detectors Work in Recycling Plus Metal Detection & Removal

Introducing metal detection technology into recycling operations often leads to a lot of practical questions about how effective it is, what kind of maintenance it needs, and what needs to be considered during operation.

We've answered the most frequently asked questions below, based on our experience installing these systems in hundreds of recycling facilities.

Which metals are the hardest to find in recycling streams?

Stainless steel is the most difficult metal to detect due to its low magnetic permeability and electrical conductivity. Austenitic grades (300 series) like 304 and 316 are especially difficult to detect within the stainless steel family, often requiring detection systems that are 30-40% more sensitive than those required for other metals. Small fragments of wire that are oriented parallel to the detection field are also difficult to detect, sometimes requiring multiple detection angles to reliably identify them. Modern multi-frequency detection systems significantly improve performance with these difficult targets, achieving detection rates that are 3-5 times better than those of single-frequency alternatives.

How frequently should metal detectors be calibrated in a recycling plant?

In a typical recycling setting, metal detectors should be tested for accuracy on a daily basis and completely calibrated once a week at the very least. If a facility processes abrasive materials or experiences large temperature changes, it may need to calibrate its metal detectors more frequently, potentially every shift. Modern detectors have automated calibration verification that runs test routines without interrupting production and only alerts operators when an adjustment is necessary. This method ensures optimal sensitivity while reducing unnecessary maintenance.

Are metal detectors capable of finding contamination in compacted bales?

The ability to detect is significantly diminished when dealing with dense, compacted materials such as baled recyclables. While metal on the surface or close to it can be detected, contamination that is deeply embedded often remains undetected until the bales are broken apart. Because of this, most high-performance recycling operations place detection systems after the bale has been broken but before the high-value processing equipment. Some facilities use specialized low-frequency penetrating detectors that are specifically designed for scanning bales, which can identify larger metal objects (typically >25mm) throughout standard recycling bales, providing a useful first screening before further processing.

How long does it usually take to see a return on investment for metal detection equipment?

Most metal detection systems that are put in place correctly usually see a return on investment in 6-18 months. This can depend on the volume of material, how often contamination occurs, and the value of the equipment downstream. Facilities that process more than 10 tons daily of highly contaminated streams like municipal recycling often see a return on investment in under 6 months. This is usually due to the avoidance of equipment damage. Operations that are focused on high-purity output for premium markets might see a return on investment through increased revenue streams. This can happen even when the risk of equipment damage is lower.

In order to precisely determine the potential return on investment, facilities need to keep track of current costs related to contamination. This includes costs for equipment repairs, downtime, quality rejections, and customer claims. A lot of equipment providers offer ROI calculators. These calculators take into account variables specific to each facility. This allows them to estimate the likely financial returns before making a purchase commitment.

How does the weather impact how metal detectors work in outdoor recycling facilities?

Changes in temperature, the presence of moisture, and electrical storms can all influence the effectiveness of detection in outdoor setups. Contemporary industrial models include environmental compensation that automatically adjusts for changes in temperature, ensuring consistent sensitivity across operating ranges from -10°C to 50°C.

Moisture can pose more significant problems, with heavy rainfall potentially leading to an increase in false positives in some systems due to alterations in material conductivity. For more insights on handling waste in challenging conditions, consider exploring the day in the life of a hazardous waste disposal technician.