Waste to Energy the Good, the Bad, the Advantages and Disadvantages

Key Takeaways

- Waste-to-energy (WTE) facilities can reduce landfill waste volume by up to 85%, addressing our growing trash crisis while generating electricity and heat.

- Modern WTE plants recover valuable metals and materials post-combustion, creating a secondary resource stream that conventional landfills cannot provide.

- While WTE produces fewer methane emissions than landfills, it still generates carbon dioxide and requires sophisticated emissions control systems to minimize air pollutants.

- The high initial cost of WTE facilities (often $100+ million) presents a significant barrier despite long-term economic and environmental benefits.

- Finding the right balance between recycling, waste reduction, and WTE technology is crucial for creating sustainable waste management systems.

The growing mountains of trash worldwide demand innovative solutions beyond traditional landfilling. Waste-to-energy technology offers a compelling alternative that transforms our garbage into valuable resources. But is it the environmental savior some claim, or does it come with hidden costs? This comprehensive analysis explores both sides of this increasingly important waste management approach.

What Is Waste-to-Energy Technology?

Waste-to-energy (WTE) refers to various processes that convert non-recyclable waste materials into usable forms of energy including electricity, heat, or fuel. The most common form involves mass-burn incineration, where municipal solid waste is combusted at high temperatures to produce steam that drives electricity-generating turbines. Modern facilities employ sophisticated emissions control systems that dramatically reduce the environmental impact compared to older incineration plants.

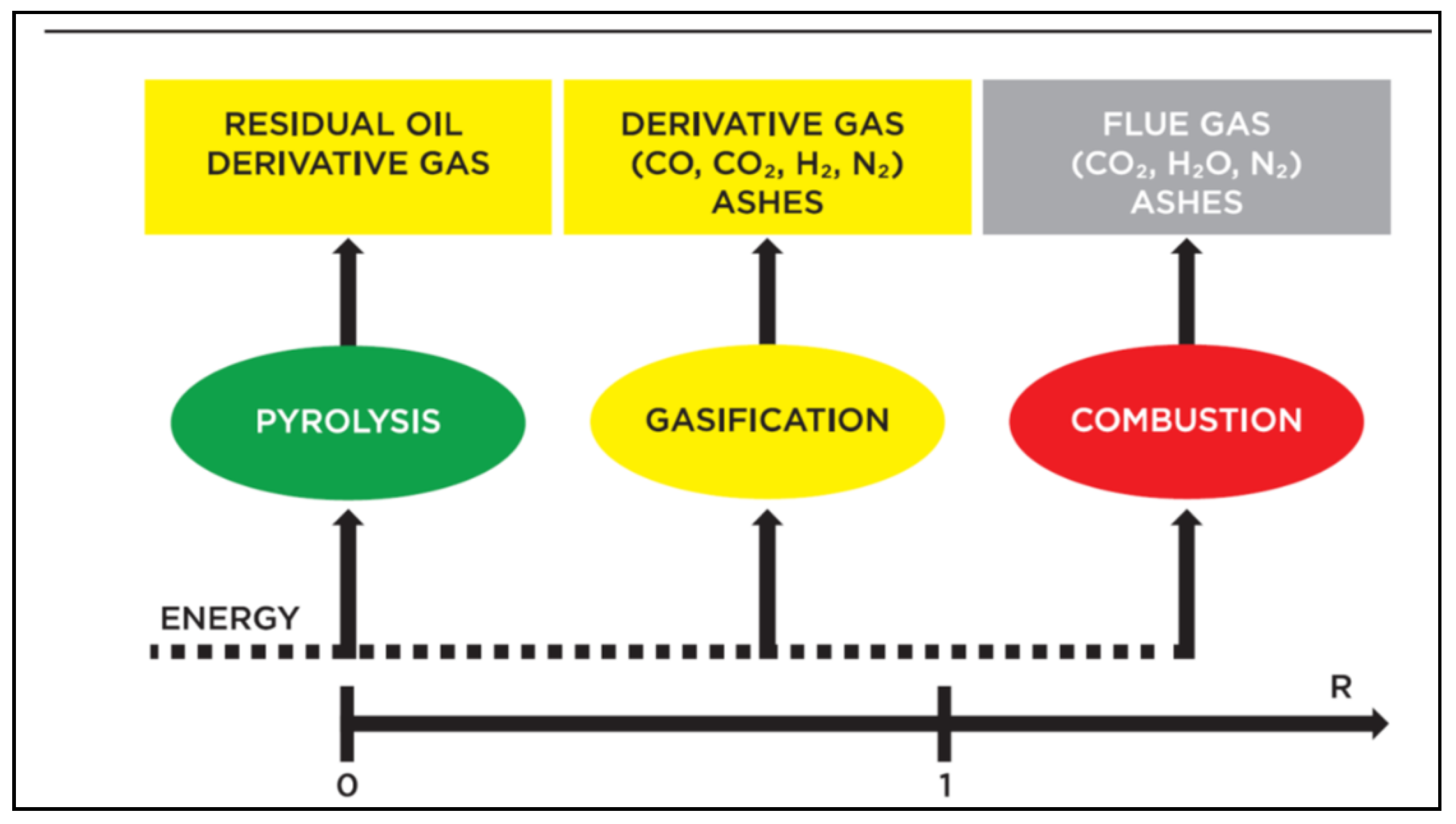

Beyond traditional combustion, newer WTE technologies include gasification, pyrolysis, and plasma arc gasification. These advanced thermal treatments break down waste at the molecular level under oxygen-controlled conditions, potentially offering improved efficiency and reduced emissions compared to conventional incineration. While less widespread than mass-burn facilities, these technologies represent the evolving future of the waste-to-energy landscape.

“Waste-to-energy (MSW) in depth – U.S …” from www.eia.gov and used with no modifications.

The Growing Global Waste Crisis

Our planet faces an unprecedented waste management challenge. According to the World Bank, global waste generation is expected to increase by 70% by 2050, reaching a staggering 3.40 billion tons annually. This waste tsunami threatens ecosystems, contaminates water supplies, and releases potent greenhouse gases as organic materials decompose in landfills. Effective solutions, such as using geomembranes and liners, can help prevent environmental disasters by containing waste and protecting natural resources.

Mountains of Trash: Our Current Disposal Problem

In the United States alone, each person generates approximately 4.9 pounds of municipal solid waste daily—that's nearly 1,800 pounds per person annually. Despite recycling efforts, the EPA reports that about 50% of this waste still ends up in landfills. These sprawling disposal sites consume valuable land, leak contaminants into groundwater, and release methane—a greenhouse gas 28 times more potent than carbon dioxide in trapping heat in the atmosphere.

The situation is particularly dire in developing nations where waste management infrastructure struggles to keep pace with rapid urbanization and population growth. Open dumping and uncontrolled burning remain common practices, creating severe public health hazards and environmental degradation. The need for sustainable waste management solutions has never been more urgent.

Why Traditional Landfills Are No Longer Enough

Landfills face mounting challenges that limit their viability as a long-term waste solution. Land availability near population centers is shrinking while transportation costs and emissions from hauling waste increase. Even modern, well-engineered landfills eventually reach capacity and require ongoing monitoring for decades after closure to prevent environmental contamination.

Perhaps most concerning is that landfills waste the energy potential contained in discarded materials. When organic waste decomposes in these oxygen-poor environments, it produces methane that typically escapes into the atmosphere unless captured by specialized systems. This represents both a climate impact and a missed opportunity to harness valuable energy resources.

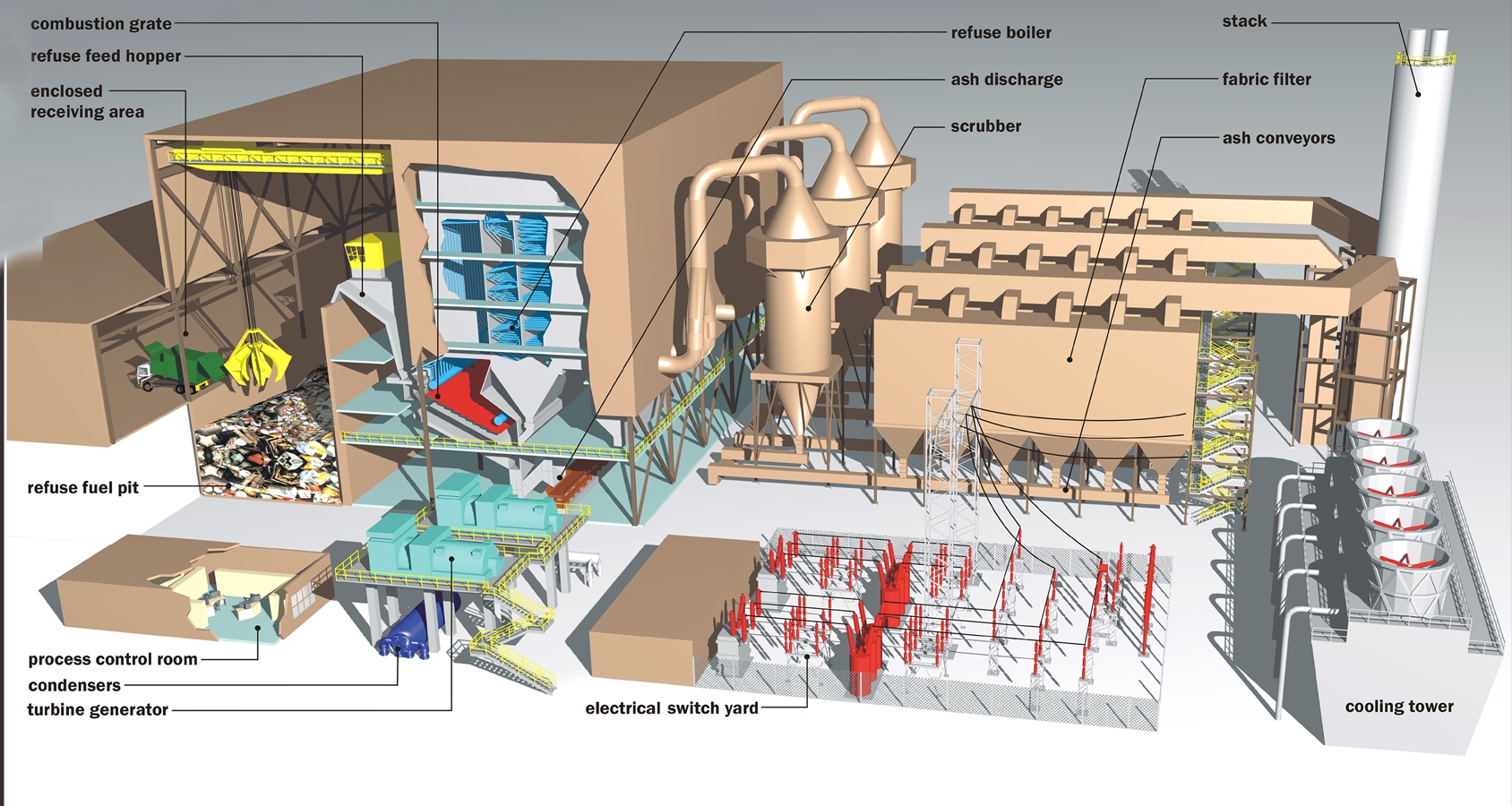

“Waste-to-Energy Facility – Pinellas County” from pinellas.gov and used with no modifications.

How Waste-to-Energy Plants Actually Work

Modern waste-to-energy facilities operate as highly engineered power plants that transform trash into electricity and heat while minimizing environmental impact. Understanding the core processes helps reveal both the benefits and limitations of this technology. For instance, exploring the biological recycling process can provide insights into alternative waste management techniques.

The Combustion Process

The journey begins when waste collection trucks deliver municipal solid waste to the facility's receiving area. After initial inspection, the waste enters a storage bunker where overhead cranes mix it to ensure relatively consistent combustion properties. The cranes then feed this mixed waste into combustion chambers where it burns at temperatures exceeding 1,800°F (982°C).

This intense heat converts water in boiler tubes to steam, which drives turbine generators to produce electricity. A typical 1,500 ton-per-day WTE plant can generate enough electricity to power approximately 25,000-30,000 homes. Some facilities also capture excess heat for district heating systems, further improving overall energy efficiency through combined heat and power (CHP) arrangements.

Modern Incineration vs.

Traditional mass-burn incineration has evolved significantly from early waste combustion methods. Today's facilities employ moving grate systems that continuously agitate waste to ensure complete combustion while computer-controlled systems monitor and adjust burning conditions in real-time. This dramatically improves efficiency while reducing problematic emissions compared to older incineration methods.

Advanced thermal technologies represent the next generation of waste-to-energy processing. Gasification converts waste into synthesis gas (syngas) by heating it with limited oxygen, while pyrolysis breaks down waste in the complete absence of oxygen. Plasma arc gasification uses electrically charged gas to reach temperatures of up to 10,000°F, completely breaking down waste molecules. These technologies potentially offer cleaner emissions profiles and greater flexibility in handling different waste streams compared to conventional incineration. For those interested in sustainable practices, exploring zero waste initiatives can provide additional insights into minimizing environmental impact.

“Thermal Treatment Emissions …” from www.mdpi.com and used with no modifications.

Emissions Control Systems

Modern WTE facilities employ multiple layers of sophisticated emissions control systems to capture pollutants before they can enter the atmosphere. Flue gas passes through selective catalytic reduction systems to remove nitrogen oxides, activated carbon injection to capture mercury and dioxins, scrubbers to neutralize acid gases, and baghouse filters to trap particulate matter as small as 10 microns—finer than a human hair. Learn more about how geomembranes and liners prevent environmental disasters in waste management.

These pollution control systems typically account for about one-third of a new facility's construction cost but are essential to meeting stringent environmental regulations. The result is dramatically cleaner operation compared to waste incinerators of previous generations, with some modern facilities achieving emission levels comparable to natural gas power plants for certain pollutants.

5 Major Benefits of Waste-to-Energy

Waste-to-energy technology offers several significant advantages when integrated properly into comprehensive waste management systems. Understanding these benefits helps explain why many developed nations continue investing in this technology despite its challenges.

1. Significant Reduction in Waste Volume

Perhaps the most immediate benefit of WTE facilities is their ability to reduce waste volume by approximately 85-90%. This dramatic reduction means that for every 100 trucks of waste entering a WTE facility, only 10-15 trucks of ash require final disposal. This volume reduction significantly extends the lifespan of existing landfills while reducing the need for new disposal sites.

The space-saving aspect is particularly valuable in densely populated regions where land availability is limited and expensive. Nations like Japan and several European countries with high population densities have embraced WTE technology partly for this reason, allowing them to manage waste streams effectively despite geographic constraints.

2. Energy Generation from Previously Unused Resources

WTE facilities transform what would otherwise be buried waste into valuable electricity and heat. A typical facility processing 1,000 tons of municipal solid waste daily can generate approximately 20-25 megawatts of electricity—enough to power thousands of homes. This energy recovery displaces fossil fuel consumption that would otherwise be needed to generate equivalent power.

The energy produced is relatively constant and predictable, unlike some renewable sources like wind and solar that fluctuate with weather conditions. This baseload characteristic makes WTE-generated electricity valuable for grid stability. Additionally, facilities that incorporate combined heat and power (CHP) can achieve efficiency rates of 80% or higher by utilizing waste heat for district heating or industrial processes.

3. Recovery of Metals and Other Materials

Modern WTE facilities recover significant quantities of metals from the waste stream both before and after combustion. Ferrous metals like steel are typically removed using magnets, while non-ferrous metals like aluminum and copper are separated using eddy current separators. A single large-scale facility can recover thousands of tons of metals annually that would otherwise remain buried in landfills.

These recovered metals enter recycling streams where they require significantly less energy to process than virgin materials. For example, recycling aluminum uses approximately 95% less energy than producing it from bauxite ore. This metal recovery represents a secondary resource stream that conventional landfilling cannot provide, further enhancing the resource recovery value of WTE facilities.

4. Less Methane Production Than Landfills

When organic waste decomposes in landfills, it produces methane—a greenhouse gas approximately 28-36 times more potent than carbon dioxide over a 100-year period. While modern landfills attempt to capture this gas, collection systems rarely exceed 75% efficiency, meaning significant methane emissions still reach the atmosphere. WTE facilities eliminate this methane production by completely combusting organic materials.

Though WTE facilities do produce carbon dioxide during combustion, the net climate impact can be lower than landfilling when accounting for avoided methane emissions. The EPA estimates that WTE facilities reduce greenhouse gas emissions by approximately 1 ton of carbon dioxide equivalent for every ton of waste processed compared to landfilling, making them potentially valuable tools in climate change mitigation strategies.

5. Job Creation and Economic Development

The waste-to-energy industry creates significant employment opportunities across multiple sectors. A typical 1,500 ton-per-day facility employs 40-60 full-time staff with diverse skills including engineers, environmental specialists, equipment operators, and maintenance technicians. These positions typically offer above-average wages and cannot be outsourced. Construction of new facilities creates hundreds of temporary jobs over 2-3 year building periods, while supporting industries like equipment manufacturing and materials handling provide additional employment.

6 Serious Drawbacks to Consider

Despite its benefits, waste-to-energy technology faces significant challenges and limitations that must be carefully evaluated. Understanding these drawbacks is essential for making informed decisions about where and how WTE fits within integrated waste management systems.

1. High Carbon Dioxide Emissions

While WTE facilities avoid methane emissions associated with landfills, they do produce significant carbon dioxide during the combustion process. For every ton of waste burned, approximately 0.7-1.2 tons of CO2 are released into the atmosphere. Though some of this carbon is biogenic (from plant-based materials that would have decomposed and released CO2 anyway), a substantial portion comes from plastics and other fossil-derived materials.

When compared to other electricity generation methods, WTE produces more carbon dioxide per kilowatt-hour than natural gas and significantly more than true renewable sources like wind and solar. This carbon intensity raises legitimate concerns about WTE's compatibility with increasingly ambitious climate goals and decarbonization targets. Learn how geomembranes and liners can play a role in preventing environmental disasters related to waste management.

Finding the Right Place for WTE in Our Waste Management Strategy

Waste-to-energy technology should be viewed as one component of a comprehensive waste management approach rather than a standalone solution. When positioned properly within the waste hierarchy, WTE can complement recycling efforts while providing a more sustainable alternative to landfilling for materials that cannot be recycled or composted. The key lies in finding the right balance that maximizes resource recovery while minimizing environmental impact.

The Waste Hierarchy: Where WTE Fits

The waste hierarchy provides a useful framework for evaluating waste management options, with prevention and reduction at the top, followed by reuse, recycling, recovery (including WTE), and disposal as the least preferred option. WTE should never compete with higher-tier strategies like recycling but rather serve as a better alternative to landfilling for non-recyclable materials. When implemented with this perspective, WTE becomes a bridge technology that supports the transition toward a more circular economy while addressing immediate waste management needs.

![]()

“Waste To Energy • WTE-Waste To Energy s …” from www.wastetoenergy.it and used with no modifications.

Complementing Recycling Programs

Countries with the highest recycling rates often also have robust WTE infrastructure, challenging the notion that these approaches conflict. Denmark, Sweden, and Germany all achieve recycling rates above 50% while sending most of their remaining waste to WTE facilities, nearly eliminating landfilling altogether. The key to this success is designing policies that prioritize recycling through economic incentives and convenient collection systems while using WTE to manage the remaining waste stream. When implemented properly, WTE facilities can even support recycling by recovering metals from the waste stream that might otherwise be missed by conventional recycling programs.

The Future of Waste-to-Energy Technology

The waste-to-energy sector is evolving rapidly with innovations focused on improving efficiency, reducing emissions, and integrating with other waste management approaches. These advancements may address many of the current limitations of WTE technology, potentially making it a more environmentally sound option in the future. From enhanced emissions control to carbon capture technologies, the next generation of WTE facilities aims to significantly reduce environmental impacts while maximizing resource recovery.

Emerging Technologies to Reduce Emissions

Carbon capture and storage (CCS) technology is being piloted at several WTE facilities globally, with the potential to transform these plants from carbon emitters to carbon-neutral or even carbon-negative operations. By capturing CO2 from exhaust gases before they enter the atmosphere, these systems address one of the most significant environmental criticisms of WTE technology. The Amager Bakke facility in Copenhagen is exploring this technology as part of Denmark's ambitious climate goals, potentially establishing a model for future facilities worldwide.

Advanced air pollution control systems continue to improve as well, with new catalytic filtration technologies that can remove multiple pollutants simultaneously while operating at lower temperatures, reducing energy consumption. These systems can achieve near-zero emissions for many regulated pollutants, addressing community concerns about air quality impacts from WTE facilities.

Smaller, More Efficient Plant Designs

The traditional model of massive centralized WTE facilities is being challenged by newer modular designs that can be deployed at smaller scales. These compact systems can process 5-100 tons of waste daily compared to the 1,000+ tons handled by conventional plants, making them suitable for smaller communities or specific waste streams. By reducing transportation distances and enabling more tailored solutions, these distributed systems may offer improved environmental performance while requiring lower capital investment, potentially making WTE more accessible to regions that cannot support large-scale facilities.

“Waste-to-Energy Pathways | EcoMENA” from www.ecomena.org and used with no modifications.

Making Smart Choices About Waste-to-Energy

The decision to implement waste-to-energy technology should be based on careful analysis of local conditions, existing waste management infrastructure, and long-term sustainability goals. There is no one-size-fits-all answer, as the right approach depends heavily on factors including population density, land availability, existing recycling rates, and energy mix. Prioritizing waste reduction, reuse, and recycling should always come first, with WTE considered primarily as an alternative to landfilling for materials that cannot be managed through higher-tier approaches. By viewing WTE as one tool within a comprehensive waste management strategy rather than a complete solution, communities can make informed decisions that balance immediate practical needs with long-term environmental goals, such as preventing environmental disasters.

Frequently Asked Questions

As waste-to-energy technology becomes more prevalent, many questions arise about its implementation, impacts, and appropriate role in sustainable waste management. The following answers address some of the most common questions based on current scientific understanding and real-world experience with modern WTE facilities.

Understanding these nuances helps communities and policymakers make informed decisions about whether and how to incorporate waste-to-energy into their waste management strategies.

Is waste-to-energy considered renewable energy?

Waste-to-energy occupies a unique position in the renewable energy spectrum. The biogenic portion of municipal solid waste—including food waste, paper, and yard trimmings—is generally classified as renewable because these materials are replenished naturally in a short timeframe. However, fossil-derived materials like plastics are not renewable. For regulatory purposes, many jurisdictions classify WTE as partially renewable, with the percentage based on the biogenic content of the waste stream (typically 50-60%). This distinction affects eligibility for renewable energy incentives and how WTE is counted toward renewable portfolio standards in different regions.

How much electricity can a waste-to-energy plant produce?

A typical waste-to-energy facility processing 1,000 tons of municipal solid waste daily can generate approximately 20-25 megawatts of electricity—enough to power about 20,000 homes. The exact output depends on several factors including waste composition, facility design, and whether the plant produces electricity alone or combined heat and power. Modern facilities achieve conversion efficiencies of 25-30% for electricity-only production, while combined heat and power systems can reach overall efficiencies of 80% or higher by utilizing waste heat for district heating or industrial processes. This energy recovery displaces fossil fuels that would otherwise be needed to generate equivalent power. To learn more about how these processes contribute to zero waste initiatives, you can explore further resources.

Are waste-to-energy plants safe for nearby communities?

Modern waste-to-energy facilities operate under some of the strictest emissions standards of any industrial sector and incorporate multiple layers of pollution control systems. These advanced controls have dramatically reduced emissions compared to older incineration plants, with many facilities operating well below permitted limits. Numerous health risk assessments conducted by independent researchers have found that properly operated modern WTE facilities do not pose significant health risks to surrounding communities. However, proper siting, rigorous maintenance, continuous emissions monitoring, and transparent reporting are essential to ensuring ongoing safety and maintaining community trust.

Why don't we have more waste-to-energy plants in the United States?

The limited growth of waste-to-energy in the United States stems from several factors, including economic challenges, public opposition, and policy environments. With relatively abundant and inexpensive landfill capacity in many regions, the higher costs of WTE facilities (often $100+ million) are difficult to justify on purely economic grounds without supportive policies. Strong “Not In My Backyard” sentiment, often based on experiences with older incineration technology, creates significant permitting hurdles. Additionally, inconsistent classification of WTE in renewable energy policies and varying waste management regulations across states create an uncertain investment environment. These barriers have limited new facility development despite the technology's wider adoption in Europe and Asia.

The last major wave of WTE construction in the US occurred in the 1980s and early 1990s, with few new facilities built since then. However, growing landfill constraints in some regions and increased interest in sustainable waste management may create new opportunities for appropriately scaled and designed WTE facilities in the future.

For communities considering waste-to-energy, extensive stakeholder engagement and transparent decision-making processes are essential to address concerns and build necessary public support.

Does burning waste in WTE plants contribute to climate change?

The climate impact of waste-to-energy is complex and depends on several factors including waste composition, energy displacement, and the alternative waste management option. WTE facilities do release carbon dioxide during combustion—approximately 0.7-1.2 tons per ton of waste processed. However, they also avoid methane emissions that would occur if the same waste decomposed in landfills. Since methane is a much more potent greenhouse gas (28-36 times more powerful than CO2), this avoidance can represent a significant climate benefit.

The EPA's Waste Reduction Model (WARM) indicates that WTE typically results in lower net greenhouse gas emissions than landfilling, even when accounting for landfill gas capture systems. Additionally, the electricity generated displaces other sources that might have higher carbon intensities, depending on the regional energy mix. For more information on sustainable practices, explore the concept of zero waste.

To further improve climate performance, some facilities are exploring carbon capture technologies that could dramatically reduce or even eliminate net carbon emissions. The climate impact of WTE should always be evaluated in comparison to realistic alternatives rather than in isolation.

For communities committed to climate action, WTE should be considered as part of a comprehensive approach that prioritizes waste reduction, reuse, and recycling while providing a better alternative to landfilling for materials that cannot be managed through higher-tier approaches.