Pre-consumer biscuit and bakery waste depackaging for animal feed is certainly a highly technical title to start this article on depackaging unsold and spoiled biscuits and bakery products for use as animal feed.

Are you grappling with the problem of how to effectively manage pre-consumer food waste? Did you know that an astonishing 70% of kitchen waste in the hospitality sector is pre-consumer food waste? This article provides innovative solutions involving anaerobic digestion and depackaging, turning time-expired biscuit and bakery waste into valuable animal feed.

Sounds interesting? Let's get started!

Key Takeaways

- Pre-consumer food waste refers to discarded or unused food materials that occur before reaching the consumer, and it can make up 70% of kitchen waste in the hospitality sector.

- Waste avoidance and reuse of waste score more highly than anaerobic digestion of waste within the waste hierarchy, and compliance with best UK practice must be the choice for these wastes over the choice of anaerobic digestion.

- Although anaerobic digestion is recognized as a highly effective method for managing pre-consumer food waste, transforming it into compost and renewable methane gas that can be used for power and heat. But, for pre-consumer waste repurposing it as an animal feed is preferred.

- Innovative depackaging machines are revolutionizing the process by separating packaging from pre-consumer biscuits and bakery waste while minimizing environmental impact. These machines help avoid microplastics in food waste recycling.

- The repurposing of pre-consumer biscuit factory and bakery waste into animal feed helps reduce waste, provides high-energy content feed for animals like pigs, and contributes to a circular economy where resources are efficiently utilized.

Definition

Pre-consumer food waste refers to the discarded or unused food materials that occur before they reach the consumer, such as in manufacturing, processing, or distribution.

Understanding Pre-consumer Food Waste

Pre-consumer food waste is food that gets thrown out before we can buy it. This waste can come from many places. It could be food that fails a quality test before it has even left a food processing factory. It could be consumable goods that get damaged or go bad after a truck's air conditioning fails to work.

It might be due to the overproduction of barbecue food unsold due to bad weather. It is frequently items from grocery stores that don't sell before they expire. Work is being done to fix this problem. People are trying to make the path from farm to store better. They want factories to use less and stores not to have too much stock on hand. But for now, something has to be done, and the preferred option for this type of food waste is repurposing it as animal feed.

The Role of Anaerobic Digestion in Managing Pre-Consumer Food Waste

Anaerobic digestion plays a big role in managing pre-consumer food waste, that is spoilt in some way and cannot be handed out for human consumption. It changes this waste into compost and methane gas.

This process only takes weeks to finish. If we separate the organic content from the rest, this method can be very good for our earth.

The methane gas that we get is renewable energy. We can use it for power and heat without negatively impacting our world. The process also doesn't make greenhouse gases to anywhere near the level that occurs when we burn or bury food waste in landfills!

Plus, after the anaerobic digestion process ends, there's more than just methane left over! The leftover material is called digestate and makes great plant food.

Pre-treatment and Management of Food Industry Waste

Food factories produce waste. That is normal. The waste is often ready for sale and inside wrappers or packages. We need to clean this off before we use the waste for other things. This is called food waste pre-treatment and is achieved using machines known as depackaging machines and separators.

Pre-treatment means we remove the organic matter from non-organic content. Organic matter includes food, plants and animal matter. Non-organic are things like plastic, metal and glass that do not come from nature.

The waste recycling industry has machines and the most advanced can do this job well. They can open packages without making small pieces known as microplastic.

In fact, 70% of our kitchen trash comes from businesses like hotels and restaurants before they serve us our meals! That's a lot of packaging!

What happens after pre-treatment? Now the food industry waste can go into an AD Digester Tank (AD stands for Anaerobic Digestion). Inside these tanks, tiny bugs eat up all the organic bits in just weeks! By eating it all up they also make compost-ready matter ready for farming use.

Even better, during their meal time these tiny bugs also fart out methane gas! And guess what? Methane gas is renewable energy which gives us clean power and heat!

So how cool is that? The food industry sends its pre-treated waste to feed microorganisms inside an AD Digester Tank and gets back compost-ready matter plus renewable methane gas!

Innovations in Food Waste Depackaging Machines

Newer generations of food waste depackaging machines, such as low-impact paddle and turbo “depackagers,” are revolutionizing the process by improving efficiency and reducing environmental impact.

Generation 1: Shredding and Milling Machines

The first-generation food waste machines were all about shredding and milling. They took big pieces of waste and made them smaller. But there was a problem. These methods led to the creation of microplastics in food waste.

Microplastics may harm our health and the environment. The process used size-reduction equipment like shredders to break down the waste. The outcome was not perfect as it mixed organic matter with tiny bits of plastic.

Generation 2: Low Impact Paddle and Turbo “Depackagers”

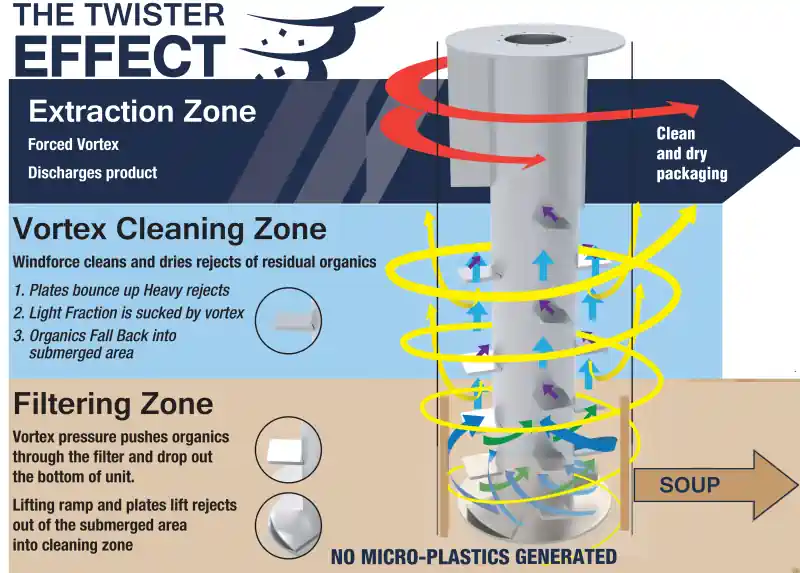

Generation 2 machines, such as the Low Impact Paddle and Turbo “Depackagers,” have been developed to effectively separate packaging from pre-consumer biscuits and bakery waste. These machines use mechanical processes such as a vortex airflow to open packaging while keeping containers like bottles and cans almost intact.

One example is the Twister food separator, which helps reduce the production of harmful microplastics in food waste. With these innovative depackaging machines, we can efficiently recover valuable organic materials for animal feed while minimizing environmental impact.

Generation 3: Advanced Food Waste Depackaging and Separation Equipment

Generation 3 food waste depackaging and separation equipment is an innovative solution for managing pre-consumer biscuit and bakery waste. This advanced equipment, such as the Twister food separator, can tear open packaging while keeping bottles and cans intact, reducing the production of microplastics.

With these machines, we can efficiently separate the food from its packaging, ensuring that the organic materials can be properly processed through anaerobic digestion or composting.

By implementing Generation 3 equipment, we can effectively reduce waste and create valuable resources like renewable methane gas and compost-ready matter in a sustainable manner.

Avoiding Microplastics in Food Waste Depackaging

To avoid microplastics in food waste depackaging, it is crucial to ensure that the organic pulp fed into the digester is free from plastic contamination. Microplastics are tiny pieces of plastic that can be harmful when ingested by animals and humans.

Therefore, careful separation and removal of any plastic packaging residues from the food waste are necessary.

One innovative machine that helps create clean, plastic-free organic pulp is the Twister machine. This machine efficiently removes packaging materials while preserving the organic matter needed for biogas production.

By using the Twister machine, we can significantly reduce the risk of microplastic pollution in our food waste management processes.

Avoiding microplastics in food waste depackaging is essential not only for protecting animal health but also for promoting environmental sustainability. It allows us to utilize food waste as a valuable resource without introducing harmful contaminants into our ecosystems.

With proper attention to this issue, we can ensure a safer and more sustainable approach to managing pre-consumer food waste.

The Future of Pre-Consumer Food Waste Management

The future of pre-consumer food waste management looks promising. Efforts are being made to optimize supply chain management and improve food processing efficiency, which can help reduce the amount of pre-consumer waste produced.

Additionally, anaerobic digestion combined with effective organics separation is seen as the most sustainable solution for managing this type of waste. This process not only converts food waste into compost-ready matter but also produces renewable methane gas that can be used for clean power and heat.

Furthermore, using food waste to produce animal feed is gaining traction as a way to reduce the need for additional grain planting for feed production. These innovative approaches show great potential in reducing environmental impact and promoting a circular economy where resources are utilized efficiently.

The Journey from Food to Animal Feed

The depackaging process separates the food waste from its packaging, allowing it to be transformed into animal feed.

Source of Raw Materials

The source of raw materials for animal feed includes pre-consumer biscuit and bakery waste. These are the leftover ingredients from making biscuits, pastries, cookies, and other baked goods.

The food industry often has excess or unused products that can't be sold to consumers but are still safe for animals to eat. Instead of throwing them away, these former foodstuffs can be repurposed into feed for pigs and cattle.

This helps reduce waste and provides a high-energy content that benefits the EU piglet market, especially during weaning. In fact, the former foodstuffs industry was valued at around €1 billion in 2014.

The Depackaging Process

The depackaging process separates organic and non-organic matter in pre-consumer biscuit and bakery waste for animal feed. Here's how it works:

- Biscuit and bakery waste, such as out-of-date bread, dough, cookies, and cakes, is collected from a single biscuit factory or from a number of food industry sources.

- The waste undergoes pre-treatment in which specialized depackaging machines are used to remove any packaging residues as described above and ensure the suitability of the organic fraction (pulp) for animal feed.

- Pelletizing machines may then be used to create pellets of the depacked biscuits and bread.

- The separated organic matter may then then processed further to create feed mixtures by adding cereals, sugars, oils, starch, dairy pelleting agents, vitamins, minerals, and other ingredients as needed.

- The resulting compound feed is a high-energy content food suitable for animals like pigs.

- This depackaged animal feed helps reduce food waste by utilizing raw material leftovers from the foodstuffs sector.

Addressing Concerns and Risks

To address concerns and risks associated with pre-consumer food waste depackaging for animal feed, measures must be taken to avoid the presence of microplastics in feed and fraudulent practices such as replacing high-quality ingredients.

Risk from Microplastics in Feed

Microplastics in animal feed can be harmful if consumed. During the depackaging process, there is a risk of microplastics being present in the feed. These tiny plastic particles can enter the mammalian gut barrier and even make their way into the bloodstream, posing a chemical burden and potential health impacts.

Microplastics may contain substances like arsenic, lead, and dioxins, which can be harmful to animals if ingested in high quantities. Although research is ongoing into just how big a problem this is, the first efforts are being made by the Waste Management industry to improve depackaging methods and technologies to minimize the presence of microplastics in animal feed.

It is crucial for environmental researchers, waste management professionals, and government officials to address this risk and work towards sustainable solutions that prioritize animal nutrition and are microplastic-free while reducing our reliance on plastics.

Avoiding Fraudulent Practice

To ensure the integrity and safety of pre-consumer biscuit and bakery waste depackaging for animal feed, it is important to take measures to avoid fraudulent practices. This includes implementing strict quality control measures, conducting regular audits, and enforcing regulations that prevent the adulteration or substitution of ingredients.

Additionally, collaborations between food manufacturers, waste management professionals, and government agencies can help create a transparent supply chain that minimizes the risk of fraudulent activity.

By maintaining high standards and promoting accountability within the industry, we can ensure that the process of repurposing food waste into animal feed remains trustworthy and sustainable.

The Role of Sorting Technology in Depackaging

Sorting technology plays a crucial role in the depackaging process of pre-consumer biscuit and bakery waste for animal feed purposes. This technology helps separate organic matter, such as food scraps, from non-organic materials, like packaging residues.

By using sorting technology, the depackaged organic waste can be efficiently processed through anaerobic digestion, where it is broken down by microorganisms to produce renewable gas and nutrient-rich digestate.

With effective sorting, the quality of the organic feedstock can be ensured by removing contaminants and unwanted materials. This not only reduces the risk of microplastics in animal feed but also contributes to sustainable waste management practices by diverting food waste from landfills or incineration.

Overall, innovative sorting technology is essential in optimizing the depackaging process and improving the efficiency of converting pre-consumer food waste into valuable resources for animal feed production.

Conclusion

In conclusion, pre-consumer biscuit and bakery waste depackaging for animal feed is a sustainable solution to reduce food waste and benefit the environment. Through innovative depackaging machines and anaerobic digestion, we can convert this waste into valuable resources like organic pulp, recycled metals and plastics, and when upgraded renewable biomethane gas is produced of the same quality as natural gas from a gas main anywhere.

By implementing these practices, we can improve waste management, minimize greenhouse gas emissions, and contribute to a more circular economy.

FAQs

1. What is the purpose of depackaging biscuit and bakery waste for animal feed?

Depackaging food waste like bread, dough, and biscuits can help in food sustainability. It reduces greenhouse gas emissions by turning food waste into piglet feed instead of it going to biogas plants.

2. How does the process work?

Food industry source separated organic feedstock gets put through a piece of 3rd generation equipment called a twister depackaging and separation machine. This tool removes packaging from off-spec products before they are made into high-quality feed.

3. Where do these actions take place?

These activities happen at places like Granico's ‘food for feed' plant in Veulen, Netherlands, among other locations in Europe including Belgium and France.

4. Who uses this type of service?

Industrial bakeries that create sweets, cakes, cookies or snacks might use such services to handle their surplus items which did not meet their strict quality requirements due to optical reasons.

5. Are there any rules related to this practice?

Yes! The EU has set maximum-permitted levels (MPLs) for plastic in animal feed as part of its circular economy strategies aimed at reducing carbon footprint and meeting Sustainability Development Goal 12.3 on food waste reduction.

6. Is this method safe for animals who eat the recycled foodstuffs?

Experts test all recyclates to ensure they're safe for consumption before becoming animal feeds ensuring low mycotoxin counts while also checking if health impact caused by compounds such as arsenic lead or dioxins aren't present.