Did you know that up to 40% of all food produced globally ends up as waste—much of it still wrapped in packaging? This shocking statistic is driving a quiet revolution in recycling. Depackaging machines, though little known, are rapidly becoming the unsung heroes of the waste management world by tackling these mountains of packaged food waste head-on.

Startling Truths About What Is Depackaging: How Depackaging Machines Are Reshaping Food Waste and Waste Depackaging

“Up to 40% of all food produced globally ends up as waste—much of which is packaged. Depackaging machines are emerging as recycling’s unsung heroes.”

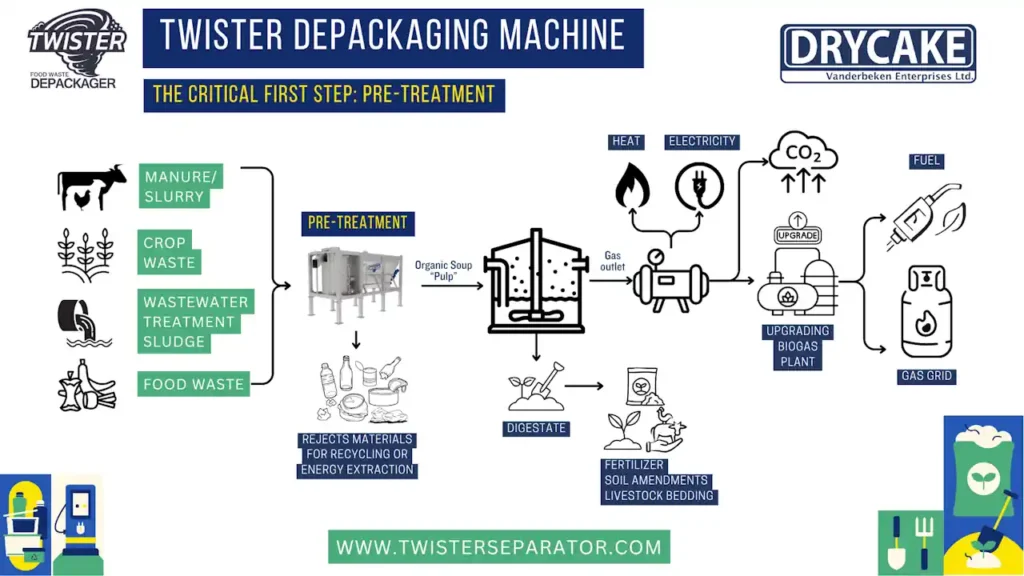

When we consider what is depackaging, most people never imagine the crucial role it plays in reshaping our environmental future. The process, and the modern machines driving it, are not merely a footnote in recycling—they are rapidly becoming the backbone of food waste depackaging and organic waste management. Depackaging separates food from its packaging, allowing the organic waste to be recycled, transformed into compost, or converted into renewable energy through anaerobic digestion—all while giving the packaging a new recycling or fuel destiny. This step is essential in building a circular economy, keeping both food and packaging out of landfills, and drastically reducing greenhouse gas emissions connected with food waste and waste streams.

In recent years, new-age depackaging equipment has stepped up to handle a wide variety of packaged food streams—from supermarket returns to food and beverage manufacturing overruns and even catering leftovers. However, older depackaging systems weren't designed with today's sustainability goals in mind. Many still chop and mill packaging into fine pieces, which contaminate the organic waste with microplastics and hinder downstream waste management efforts. As the industry shifts, the question of upgrading to modern technology looms large—unfortunately, few incentives exist to accelerate this change.

What You'll Learn in This Guide About What Is Depackaging and Food Waste Depackaging

- The definition and core purpose of depackaging

- The technology and systems that drive modern waste depackaging

- Benefits to food waste management, organic waste recycling, and sustainability

- Challenges facing outdated depackaging equipment and technology

- How the future of waste management relies on better depackaging solutions

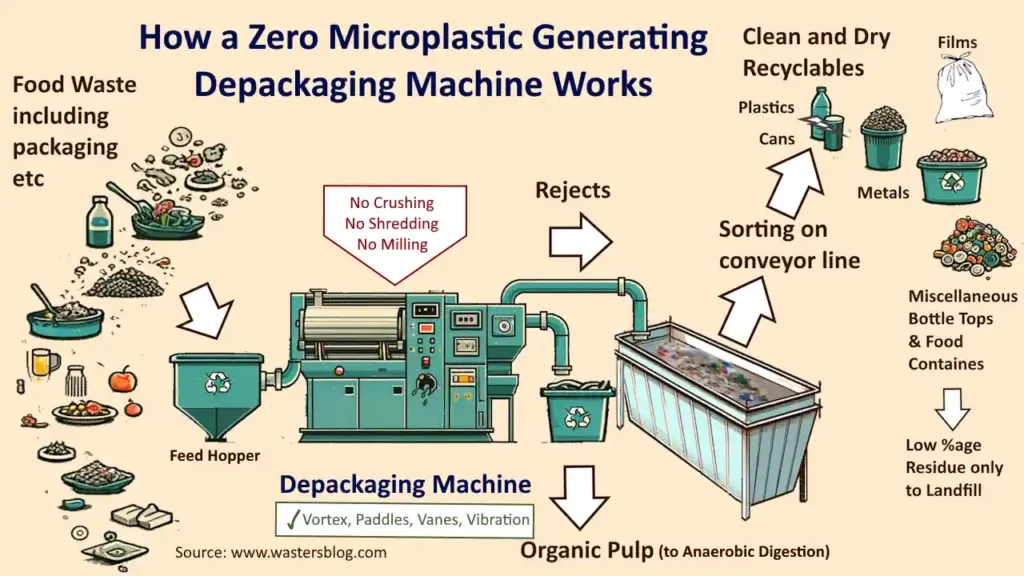

An infographic showing – How a Depackaging Machine Works.

An infographic showing – How a Depackaging Machine Works.

Table: Comparing Old vs Modern Depackaging Systems for Managing Food Waste and Organic Waste

| System Type | Efficiency | Output Quality | Maintenance | Suitability for Anaerobic Digestion | Suitability for Recycling | Environmental Impact |

|---|---|---|---|---|---|---|

| Old Mechanical Depackaging | Moderate; struggles with mixed and wet wastes | Low; higher levels of contaminated organic waste and shredded plastics | High; frequent downtime, abrasion issues | Poor; microplastic contamination limits biogas yields | Limited; shredded packaging hard to recover/recycle | Negative; creates microplastics, undermines sustainability |

| Modern Gentle-Action Depackaging | High; handles a wide variety and moisture contents | Excellent; produces clean, separated organics and packaging | Low; robust, designed for easy cleaning | Excellent; enables effective, high-yield anaerobic digestion | High; recovered packaging suitable for recycling or RDF/SRF | Positive; reduces landfill, microplastics, and greenhouse gases |

What Is Depackaging? A Comprehensive Definition in Waste Management Systems

At its core, depackaging is the automated (or sometimes manual) removal of packaging materials from their contents—typically food or other organic substances. This process is crucial for waste management systems and recycling industries worldwide. It enables industries and municipalities to separate food and organic waste from their wrappers, plastic, cans, cartons, or glass, ensuring each component follows its most environmentally responsible path. Without waste depackaging, much of the food and packaging waste generated in homes, supermarkets, and factories would end up in landfill. This increases greenhouse gas emissions and frustrates composting or biogas production efforts.

The depackaging process underpins a successful waste stream or organic waste management system. Clean, separated organics can be processed for composting, animal feed, or renewable energy. Meanwhile, packaging materials—if intact—can be recycled or even repurposed as fuel. By embracing advanced depackaging technology, businesses and governments play a vital role in the circular economy and sustainability goals. However, the real-world effectiveness of this solution depends greatly on the generation of cleaner, uncontaminated material streams—a challenge met only by the most modern depackaging equipment.

How Depackaging Works: Separating Food from Its Packaging

Depackaging systems are engineered to efficiently separate food from its packaging using a blend of mechanical, pneumatic, or sometimes hydraulic forces. When packaged food waste enters a depackaging machine, it's conveyed through a series of mechanisms designed to gently remove and isolate the organic contents. Typically, rotating paddles, augers, or adjustable beaters break the seal of wrappers and containers, releasing the food inside without severely shredding the packaging.

This separation is crucial for two reasons: first, clean organic material is vital for effective composting or producing biogas via anaerobic digestion; second, intact or chunky packaging material is easier to recover for recycling or conversion to fuel. Modern depackaging equipment often features smart sensors and adjustable controls to tune the process for various waste types, ensuring both streams are as pure as possible.

The Role of Depackaging in Food Waste and Food Waste Depackaging

Industries and municipalities face daunting volumes of food waste and expired packaged food every day. Depackaging acts as a vital intermediary, enabling the responsible diversion of these streams away from landfill while maximizing the value of organic waste. By separating edible components from their wrappers, waste depackaging not only unlocks the potential for anaerobic digestion and composting, but helps meet legislative requirements for organic and food waste management.

The impact is transformative: with clean, uncontaminated waste streams, facilities can achieve higher biogas yields, improved compost quality, and lower greenhouse gas emissions—directly supporting local and global sustainability goals. The ongoing wave of food waste depackaging enables everything from animal feed production to renewable fuel generation, closing multiple loops in the circular economy.

Applications: From Food and Beverage to Organic Waste Management

The scope of depackaging technology extends well beyond supermarket returns. Today, advanced depackaging systems are a cornerstone for food and beverage manufacturers, logistics centers, and municipal composting operations—anywhere significant amounts of packaged food or mixed organic waste are produced.

For example, beverage plants may have batches of expired soda, all in cans or bottles; a depackaging solution is deployed to separate the liquid contents (recoverable for energy, composting, or even as ingredients for animal feed) from recyclable packaging. Similarly, organic materials from food retailers—think bakery returns, dairy overruns, or fresh produce past its date—are handled efficiently by depackaging equipment, maximizing both waste diversion and resource recovery.

The Depackaging Process: From Packaged Food to Clean Organic Waste

Steps in the Depackaging Process for Waste Streams

The depackaging process can be summarized in a series of critical stages that transform mixed waste streams into valuable separated organics and recyclable packaging. First, the bulk packaged food waste is loaded into an intake hopper, where initial size-reduction or sorting may occur. Next, the mixed waste enters the main separation chamber—home to the heart of the depackaging system—which uses a combination of agitation, pressure, and screening to gently release food from wrappers, containers, or bottles without excessive shredding.

The organic material, now free from packaging, moves through conveyors or augers to storage tanks or bins, ready for composting, anaerobic digestion, or animal feed production. Meanwhile, non-organic packaging materials are conveyed to separate bins or balers for recycling, RDF (Refuse Derived Fuel), or further sorting. Modern systems utilize automated detection to minimize manual labor and maximize the quality of both waste streams, ensuring compliance with strict environmental regulations and boosting the overall efficiency of waste management systems.

Key Technologies and Depackaging Equipment Used

Today’s top-performing depackaging systems showcase an array of advanced features—ranging from heavy-duty augers, paddle feeders, gravity separation, and even pressurized washing. The most critical element of depackaging equipment is its ability to separate food from its packaging while preserving both streams’ purity, which is especially vital in food waste depackaging and organic recycling. Adjustable components allow for precise handling of different waste textures—wet, dry, fibrous, or even sticky items—while robust construction minimizes wear and ongoing maintenance.

State-of-the-art machines sometimes include optical or density-based sorters to automatically identify and further purify streams after primary depackaging. Their modular design also facilitates easier upgrades as technology evolves. Ultimately, the type of depackaging solution selected depends on input material, desired output purity, and downstream application—such as direct composting, anaerobic digestion, or packaging recycling.

See workers overseeing highly automated lines as food waste is gently separated from plastic and cans, with final outputs sorted into bins for biogas and recycling. (Video coming soon!)

Benefits of Depackaging Technology: Reducing Greenhouse Gas and Improving Waste Management

- Resource recovery from food waste depackaging

- Reducing landfill and greenhouse gas emissions

- Supporting anaerobic digestion and renewable fuel creation

- Enabling recycling and composting of organic waste

Modern depackaging technology provides a bridge from linear, landfill-heavy waste systems to circular, sustainable waste management solutions. By efficiently separating food and organic waste from packaging, depackaging enables businesses and cities to send the clean organic stream toward composting or anaerobic digestion. This not only diverts mountains of waste from landfill—where it would produce harmful methane, a potent greenhouse gas—but also generates valuable outputs like nutrient-rich compost or biogas for power and heat.

The packaging fraction, kept in larger, discrete pieces instead of being shredded, can be more easily recycled or repurposed as Refuse Derived Fuel (RDF) or Solid Recovered Fuel (SRF), further reducing the environmental impact. Altogether, the adoption of state-of-the-art depackaging systems bolsters our progress towards closed-loop resource recovery, sustainability, and lower fossil fuel reliance.

“Solid Waste Depackaging | Tecnofer …” from www.youtube.com and used with no modifications.

Challenges with Outdated Depackaging Systems: The Plastic Pollution Dilemma

“Older depackaging equipment often chops plastics into pieces too small to recover, worsening microplastic pollution risks.”

“Food Depackaging: The Systems | BioCycle” from www.biocycle.net and used with no modifications.

How Old Depackaging Equipment Fails Waste Management and Organic Waste Goals

Despite the clear environmental advantages, many waste depackaging facilities still rely on older-generation machines—systems that were not engineered for separating today's complex packaged food waste streams. Their blunt approach (chopping, crushing, and heavy milling) reduces labor costs but devastates the purity of both resulting streams. Plastics and packaging are shredded into fragments so small they escape recycling and pass through into the organic stream, contaminating potential compost or biogas substrate with microplastics or other pollutants. Not only does this undermine sustainability goals, but it can render the organic output unfit for land application, animal feed, or even aerobic digestion.

At the same time, the packaged waste fraction loses its calorific value, becoming less useful as RDF or SRF fuel and even more difficult and costly to manage. The labor and maintenance intensity due to increased abrasion and equipment wear further weakens the economic case for outdated systems. As plastics become ever more prevalent in modern food packaging, only new, gentle-action technologies equipped with smart sensors and precision controls can preserve the value—and sustainability—of both output streams.

Critically Assessing the Need for New Depackaging Technology

The limitations of legacy depackaging equipment highlight an urgent need for widespread adoption of advanced depackaging solutions. Industry experts warn that, in the absence of large-scale upgrades, the recycling sector could unintentionally exacerbate the global plastic pollution crisis rather than solve it. Forward-thinking waste managers and policy leaders increasingly recognize the essential role of next-generation machines—not only for compliance, but for true environmental stewardship.

Upgrading requires notable investment, but the long-term benefits—higher resource recovery, minimized microplastic release, and valuable organic outputs—more than justify the cost. However, misaligned or absent policy incentives mean that cash-strapped operators are slow to replace legacy machines, even as pressures from regulators, the public, and downstream agricultural users mount.

Incentives and Barriers: The Policy Gap in Upgrading Depackaging Systems

Why Are There So Few Incentives for Modern Depackaging Equipment?

Many governments and municipalities acknowledge the urgency of tackling food waste depackaging and plastic pollution. However, few offer targeted financial or regulatory incentives to spur the widespread adoption of modern depackaging technology. This gap means operators must often justify upgrades on narrow financial grounds alone—tricky when the upfront cost of new machines is high, and immediate returns are hard to quantify within typical municipal or industrial contracts. The lack of policy focus on contamination reduction, output quality, and downstream compatibility further slows progress, leaving much of the sector reliant on outdated, ineffective depackaging systems.

How Government Policy Can Support Sustainable Waste Depackaging

Effective policy could dramatically accelerate the transition to best-in-class depackaging equipment. By setting output purity standards, mandating contamination thresholds, or providing grants, low-interest loans, and accelerated depreciation for upgrades, lawmakers could create strong incentives for operators to invest in high-performing, low-waste solutions. For the circular economy to thrive, depackaging machines must be recognized—and incentivized—as the critical link in the resource recovery chain. Such actions not only benefit waste managers but protect the environment, support local agriculture, and fulfill community sustainability goals.

Watch an expert interview on the future of depackaging and the policy role in supporting sustainable waste management systems. (Video coming soon!)

People Also Ask: What Is Depackaging and Related Queries

What is the meaning of depackaging?

Depackaging refers to the automated or manual process of separating the contents (such as food or organic waste) from their packaging materials, enabling effective recycling, composting, or further treatment of both the separated packaging and the unpackaged waste.

What is an example of a biodegradable food?

A biodegradable food is one that naturally breaks down through microbial or enzymatic action, such as apple cores, eggshells, or bread. These foods can be separated from packaging and used for composting or biogas through depackaging processes.

What is depack?

‘Depack’ is shorthand for depackaging—the process of removing packaging from food or other consumable goods for the purpose of waste management or recycling.

Is depackaging a word?

Yes, ‘depackaging' is a technical term widely used in the waste management and recycling industries to describe the process of separating product contents from their packaging.

FAQs: What Is Depackaging in Waste Management Systems

What types of packaging can be processed using modern depackaging systems?

Modern depackaging systems are engineered to handle a wide variety of packaging formats: plastic wrappers, cardboard cartons, cans, glass, Tetra Paks, and vacuum-sealed pouches. The most advanced machines automatically adjust for product type, moisture level, and packaging density, ensuring both the separated organic material and the packaging output meet the requirements for recycling, composting, or further treatment. This flexibility is essential for waste handlers working with variable waste streams from retailers, manufacturers, or municipal sources.

Can depackaging technology handle all types of organic waste and food waste?

While modern depackaging technology is versatile enough to process most forms of packaged food—frozen, liquid, canned, baked goods, and produce—not every type of waste stream is suitable. Certain sticky, fibrous, or highly mixed wastes may require pre-treatment or manual sorting. However, ongoing innovations continue to expand the range of input materials, boosting recovery rates and overall efficiency across the food and organic waste depackaging landscape.

What are the environmental impacts of advanced depackaging systems?

The environmental benefits of next-generation depackaging equipment are profound: by reliably delivering clean, uncontaminated organic streams, they enhance the efficiency of anaerobic digestion, composting, and recycling processes. This reduces landfill tonnage, curbs the release of methane and other greenhouse gases, and dramatically shrinks the risk of microplastic pollution. Additionally, maximizing packaging recovery helps meet recycling targets and reduces the carbon footprint associated with extracting and manufacturing virgin materials.

Is there a significant cost difference between outdated and new depackaging equipment?

While the initial investment in modern depackaging machines is higher, the long-term operational savings (from lower maintenance, better output value, and reduced contamination penalties) quickly bridge the gap. Moreover, future-proof depackaging solutions position operations to meet today’s—and tomorrow’s—environmental standards, potentially attracting grants, subsidies, or preferred contract status for forward-looking waste managers.

Key Takeaways: Why What Is Depackaging Is Essential for Food Waste and Organic Waste Solutions

- Depackaging is critical for effective food waste management.

- New depackaging technologies reduce environmental harm from packaging and support circular waste streams.

- There is an urgent need for policy-driven adoption of advanced depackaging systems.

Conclusion: Advancing Food Waste Depackaging Through Innovation

“Without investment in modern depackaging technology, recycling may worsen the plastic pollution crisis rather than fix it.” – Industry Expert

To unlock the full sustainability potential of waste depackaging and keep the circular economy moving, replacing outdated machines with state-of-the-art depackaging solutions is essential.

Call to Action

If you found this article interesting, consider visiting https://twisterseparator.com

Sources

- UNEP Food Waste Index Report 2021

- EPA Sustainable Management of Food

- Waste Advantage Magazine: The Importance of Depackaging Organics

- Zero Waste Europe: Biowaste Management

Depackaging is the process of separating organic materials, such as food waste, from their packaging to facilitate recycling, composting, or energy recovery. This method is crucial in waste management, enabling the efficient processing of unsalable or expired food items while minimizing environmental impact.

Modern depackaging systems employ advanced technologies to handle various packaged goods, including expired groceries, production rejects, and overstocked inventory. These machines utilize mechanical forces—such as grinding, shredding, or agitation—to break open packaging and release the contents. The organic material is then separated from the packaging through screening and filtration processes, resulting in clean, contaminant-free organic matter suitable for composting or anaerobic digestion. The remaining packaging materials are sorted for recycling or responsible disposal. (ecorichenv.com)

The benefits of depackaging are multifaceted. By diverting organic waste from landfills, depackaging reduces methane emissions—a potent greenhouse gas—and conserves landfill space. The recovered organic materials can be converted into biogas or biofuels through anaerobic digestion, contributing to renewable energy production. Additionally, depackaging enhances resource recovery by extracting valuable recyclates like plastic resins, supporting a circular economy where materials are reused rather than discarded. (depackagingequipment.com)

In the retail sector, companies like Walmart have implemented large-scale depackaging programs to improve sustainability efforts. By deploying depackaging technology across numerous stores, Walmart has increased its organics recycling rate, demonstrating the scalability and effectiveness of depackaging in reducing food waste and promoting environmental responsibility. (packworld.com)

In summary, depackaging plays a pivotal role in modern waste management by efficiently separating organic waste from packaging, thereby reducing landfill contributions, lowering greenhouse gas emissions, and facilitating the recovery of valuable resources.