A comprehensive guide to mastering a product's full life cycle analysis. In other words, why it makes sense for any business to prepare and use a life cycle analysis of a product, and how to set about doing it.

Struggling to understand how products impact the planet?

A Life Cycle Assessment (LCA) can reveal this. The following guide explains how you can master an LCA for any product, step by step. Get ready to become an expert!

Life Cycle Analysis Of A Product: Key Takeaways

- Life Cycle Assessments (LCAs) check the environmental cost of products from start to finish. They help stop greenwashing by showing if products are truly eco-friendly.

- Three types of LCAs—cradle to grave, cradle to cradle, and cradle to gate – each offer different insights into a product's impact on our planet. These follow strict ISO standards 14040 and 14044 for accuracy.

- LCAs play a big role in decision-making across industries, government, and NGOs. They use these assessments to choose greener options and create policies that protect the environment.

- Environmental Product Declarations (EPDs) share clear details about a product’s whole life cycle impact. This helps businesses show they are serious about reducing harm to the environment.

- Practicing LCAs can lead companies toward better sustainability strategies by highlighting areas for improvement, like using cleaner energy or making less waste.

The Importance of Life Cycle Assessments (LCAs)

Life Cycle Assessments (LCAs) shine a light on the environmental cost of products from start to finish.

They push us to think about green choices early on in product design, fighting off greenwashing that tricks people into thinking they're buying eco-friendly goods when they're not.

They are important because, without applying them society may end up acting in ways that damage the planet despite having the best of intentions.

Environmental impact assessment from extraction to disposal

Assessing the environmental impact of a product covers its entire journey. This starts from pulling raw materials out of the earth to tossing the final product away. Every step matters, from mining, manufacturing, and using, to finally disposing or recycling.

This whole process of studying and writing the life cycle analysis of a product helps us see how much we harm our world. It's like putting everything on a scale to measure its true cost to nature.

To do this well, we use something called Life Cycle Assessments (LCAs). These studies follow strict rules set by ISO standards 14040 and 14044 to make sure they're done right. They tell us about things like carbon footprints and how much energy a product uses throughout its life.

Knowing all this influences big decisions in industry, government, and even non-government organisations about what products are okay for our planet.

Next up is why early planning with LCAs can save time and our environment. Starting to assess the life cycle analysis of a product can never start too soon!

Early consideration in project development

Understanding the environmental effects from start to finish is only the beginning. Thinking about life cycle analyses (LCAs) early in project creation is vital. It helps teams spot potential impacts and areas for improvement right away.

This approach isn't just smart—it's necessary for creating projects that truly stand up to green scrutiny.

Starting with an LCA to analyse the life cycle analysis of a product early gives planners, builders, and thinkers the tools they need to make informed choices. These choices shape not just the product but also its journey through the manufacturing, use, and disposal stages.

Whether you're a waste management expert or a policymaker, this knowledge guides your decisions toward more sustainable outcomes.

Rise in attention due to greenwashing

As we consider the early stages of project development, it's vital to address how greenwashing has shifted focus towards the need for life cycle assessments (LCAs) conducted in accordance with international standards.

Companies often make eco-friendly claims about their products. Yet, without thorough LCAs, these statements may not hold up. This issue has caught the eye of both the public and the media. They demand more transparency in environmental impact reports.

Misleading advertising about sustainability can confuse consumers and harm trust in green initiatives. That's why accurate LCAs are crucial. They offer a detailed evaluation from product creation to disposal, ensuring companies back up their eco-friendly claims with solid data.

This shift leads to better-informed decisions by businesses and consumers alike, pushing for genuine sustainable practices across industries. Unless using the results of a life cycle analysis of a product even a sustainability expert is just giving an opinion on a complex matter.

Different Types and Scopes of LCAs

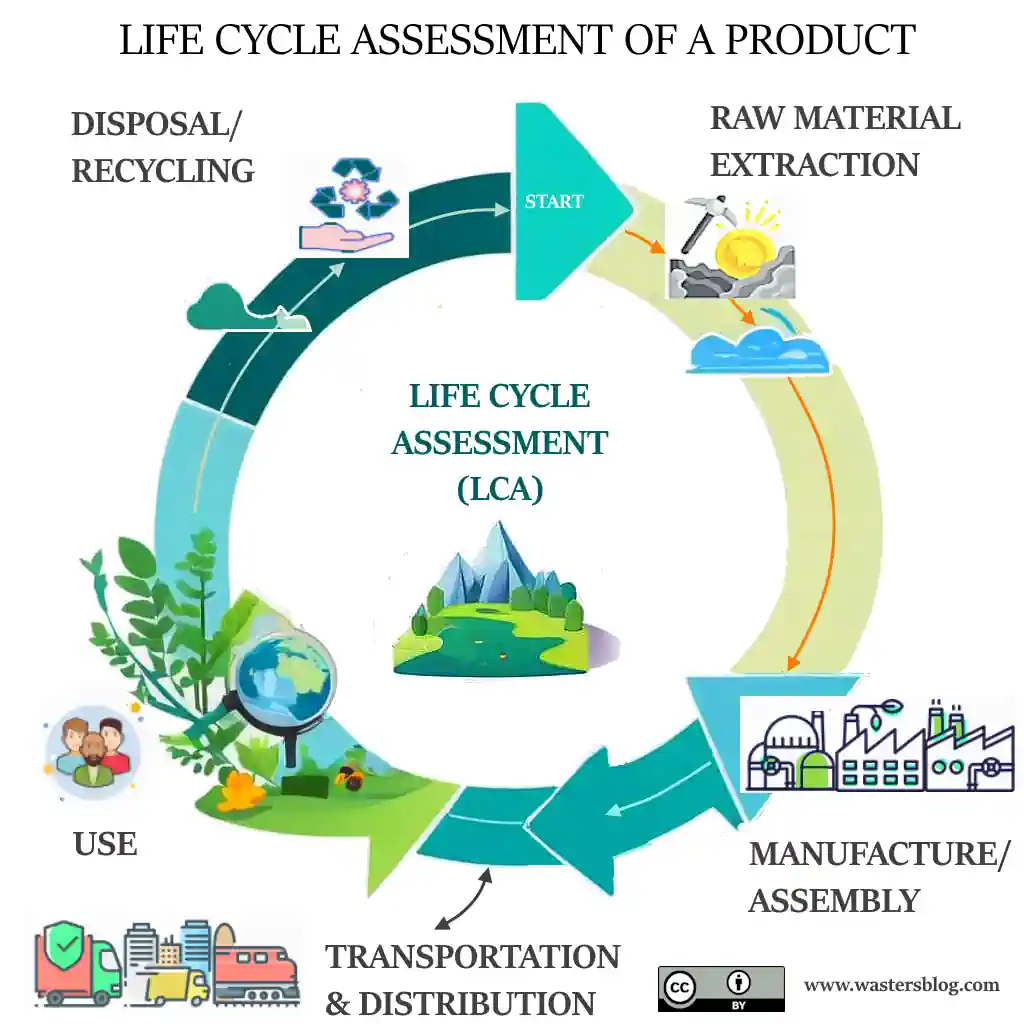

Exploring LCAs reveals a world where every product's journey is scrutinised. From cradle to grave, cradle to gate, and even cradle to cradle. Each path offers unique insights into how the things we make and use impact our planet.

These assessments should always stick closely to standards set by ISO 14040 and 14044, ensuring every study is up to the mark.

Cradle to grave, cradle to cradle, cradle to gate

Life Cycle Assessments (LCAs) shine a light on how products impact our planet. They help us understand everything from creation to disposal. Here's a closer look at three common types: cradle to grave, cradle to cradle, and cradle to gate.

- Cradle to Grave: This type covers a product's journey from raw materials to its end as waste. It gives us a full picture of environmental footprints through all stages—making, using, and throwing away. For instance, when we think about a plastic bottle, cradle to grave assesses the impact from producing the plastic, filling it with water, shipping it across miles, and finally disposing of it.

- Cradle to Cradle: Rather than ending in disposal, this approach focuses on recycling or reusing materials indefinitely. It champions sustainable development by thinking beyond the bin. Imagine that plastic bottle being recycled into new bottles or even clothing. This model pushes for materials that can live on in new forms.

- Cradle to Gate: This zooms in on production up until the product leaves the factory gate but doesn't cover its use or disposal by consumers. It's heavily used in eco-design and sustainable manufacturing, ensuring products are green from the start. If we consider an electronic device like a smartphone, cradle to gate evaluates environmental impacts up until it's packaged and shipped off.

Each LCA technique has its place depending on project goals and industry standards such as ISO 14040/44. They guide decisions in business strategies, regulatory compliance, and marketing campaigns related to sustainability.

Through these assessments, companies can reduce negative impacts on climate change and ecosystems while improving energy efficiency and reliability.

When to Use Cradle to Grave versus Cradle to Gate

The scope of the LCA is different for each study because it is tailored to the client's goals.

One option is to take a “cradle to grave approach,” which looks at all the steps, from the raw materials to the final disposal.

‘Cradle to cradle' is the most thorough method because it looks at all steps of a product's life, from its creation to its reuse. This shows the full environmental impact of the product.

If you want a simpler and cheaper way to do things, you should take a “cradle to gate” view. This looks at the effects from the time the raw materials are extracted to the time they are sent to the maker.

Adherence to ISO standards 14040 and 14044

Following ISO standards 14040 and 14044 is key for doing life cycle assessments (LCAs) right. These rules make sure LCAs can be trusted, especially when shared outside the organisation.

They cover everything from setting goals to interpreting results. This makes them a solid base for any LCA study aiming to measure a product's real impact on the environment.

For studies meant for others to see, sticking to these standards is a must. They help avoid confusion by providing clear methods for gathering and analysing data about energy use, waste management, carbon management, and more.

By keeping these practices in check, organisations can communicate their sustainability efforts more clearly and effectively.

Applications of LCAs (Life Cycle Analysis of a Product)

Life Cycle Assessments have big roles in making choices across various fields. They guide industries, governments, and groups with a cause to pick greener paths.

Decision-making in industry, government, and non-government bodies

In industry, leaders use life cycle assessments (LCAs) to make smart choices. They look at the whole journey of a product, from start to finish. This helps them find ways to be more eco-friendly and cut costs.

LCAs guide companies in picking materials that do less harm to our planet. They also help figure out if a new product is truly better for the environment.

Governments and NGOs rely on LCA results too. These findings shape policies that aim for sustainability and reduce waste. By understanding a product's full impact, these bodies can set standards that encourage greener practices across various sectors.

This leads to rules that support our world's health and future generations' well-being.

Comparative claims and sustainability communication

Clients often use life cycle assessment (LCA) results to make comparative claims. They tell customers about the benefits of their goods. This method helps them show their dedication to keeping our planet healthy.

It's a clear way of saying, “We care about the environment.” Using transparent and credible comparisons can highlight a product's green advantages. This approach puts brands in the spotlight as sustainability champions.

Life cycle analysis (LCA) also lets companies share how they are working towards better environmental practices. Environmental Product Declarations (EPDs) play a big role here. They give honest and checked information on how products impact nature from start to finish.

This transparency is key for everyone involved – from makers to users.

Next up, let's explore how LCAs help with following rules and offering support.

Regulatory compliance and support

Moving from how companies use life cycle assessments (LCAs) to communicate their sustainability efforts, we see that LCAs are vital for meeting legal requirements too.

Many industries across the globe find themselves in a position where they must comply with strict environmental regulations.

An LCA provides them with a detailed review of their products’ ecological footprints—from raw material extraction to disposal. This helps businesses ensure they're not just claiming to be eco-friendly but are actually making strides towards reducing adverse environmental effects.

Environmental Product Declarations (EPDs)—certificates showing data on a product’s environmental impact throughout its journey—play a crucial role here. They serve as proof that an enterprise has done its homework, understanding and minimising the potential harm its offerings could cause our planet.

Governments and regulatory bodies often require such documentation before allowing goods into the market or granting tax benefits. Hence, implementing LCAs can smooth out this process, acting as both a shield and support against non-compliance issues while fostering trust among consumers and stakeholders alike.

Benefits of LCAs

LCA results shine a light on how companies can be more open and honest with us. They give out Environmental Product Declarations (EPDs) that tell you exactly what impact a product has on our planet.

This makes it easier for everyone to spot the good guys from the not-so-good ones in business. Plus, by using LCAs, firms can keep getting better at being green. It opens up new ways for them to think about and act on sustainability, like finding cleaner energy sources or cutting down waste.

These steps are big wins for both the earth and businesses wanting to stay ahead in a world that cares more about being kind to our environment every day. Keep reading to see how diving into the details of LCAs could help make a greener future happen!

List of LCA Benefits

At a more detailed level, Life Cycle Analysis (LCA) offers numerous benefits for businesses, governments, and society at large, especially in terms of environmental sustainability and strategic decision-making.

Here are some of the key benefits:

- Environmental Impact Reduction: LCA helps identify the stages of a product’s life where environmental impact is most significant, guiding efforts to reduce carbon footprints, resource use, and waste generation.

- Informed Decision-Making: By understanding the full environmental cost of products from cradle to grave, companies and policymakers can make more informed choices about design, production, and policy that align with sustainability goals.

- Enhanced Product Design: LCA provides insights that can lead to designing more efficient, sustainable products that use fewer resources, generate less waste, and are easier to recycle or dispose of responsibly.

- Regulatory Compliance and Risk Management: As regulations around environmental impact tighten, LCA can help companies stay ahead of legal requirements and manage risks associated with environmental liabilities.

- Market Differentiation and Competitive Advantage: Businesses using LCA can differentiate their products on the basis of sustainability, appealing to consumers and clients who prioritize environmental responsibility.

- Cost Reduction: Identifying inefficient use of resources and energy throughout a product’s lifecycle can lead to cost savings through improved processes, reduced waste, and more efficient use of materials.

- Stakeholder Communication and Transparency: LCA results can be used to communicate a company’s commitment to sustainability, enhance brand reputation and build trust with customers, investors, and regulators.

- Supply Chain Optimization: By analyzing the life cycle of products, companies can identify opportunities to improve supply chain logistics, reduce energy use, and minimize environmental impacts in transportation and production.

- Supports Circular Economy Initiatives: LCA is integral to developing circular economy strategies, where the goal is to minimize waste and make the most of resources by recycling, reusing, and refurbishing products at the end of their lives.

- Global Sustainability Contributions: On a larger scale, widespread use of LCA can contribute to global sustainability efforts, such as reducing greenhouse gas emissions, conserving biodiversity, and protecting ecosystems.

LCA is a powerful tool that can guide more sustainable business practices and product development, reflecting an organization's commitment to minimizing its environmental footprint and contributing positively to the world.

Transparency and accountability for stakeholders

LCAs shine a light on the environmental actions of companies. They offer clear, verified details about how products affect our planet from start to finish. This open information lets investors, customers, and local groups see how businesses are doing their part for the environment.

With a life cycle analysis of a product, It's all about being upfront and taking responsibility.

With Environmental Product Declarations (EPDs), firms can show everyone just how green they are. Think of EPDs as report cards for sustainability — showing off good grades in being kind to our world.

This way, making greener choices becomes easier for everyone involved.

Moving on, let's talk about the role of LCAs in shaping sustainable technology strategies.

Environmental Product Declarations (EPDs)

Moving from the idea of transparency and accountability, let us now look in more detail at Environmental Product Declarations (EPDs).

Increasingly, they will serve as a vital tool.

They offer clear, verified details about how products affect the environment over their whole life cycle.

Think of EPDs as report cards that spell out everything from greenhouse gas emissions to energy use.

Companies around the world use EPDs to show they're serious about reducing environmental harm. These documents follow ISO standards 14040 and 14044, making sure every detail meets strict guidelines.

Authors Euan Munro and Becca Shaikh of SLR Consulting have shared insights into how EPDs guide industries towards greener choices. This approach helps everyone understand a product's true impact on our planet – from creation to disposal.

Adaptation and evolution of sustainability strategies

Life Cycle Assessments (LCAs) are key for companies to shape and change their green plans over time. They respond to what people want — clear proof of a firm's eco-friendly actions.

With this tool, firms can show they are serious about cutting down harm to our planet. It guides them in using resources wisely and reducing risks.

Using LCAs, businesses can keep up with the shift towards a circular economy by always looking for ways to improve. They take on new approaches like cleaner production methods or recycling rather than binning goods.

Each step is backed by solid facts from life cycle inventory data, making sure every move is aimed at lessening environmental harm. Next, let's explore how practical experience plays a role in delivering impactful LCA studies.

Case Study: SLR's LCA Expertise

SLR knows a lot about life cycle assessments (LCAs). They use smart practices and tools to study how products affect the environment from start to finish.

Practical experience in delivering LCA studies

SLR's team brings a wealth of know-how to Life Cycle Assessments (LCAs), handling projects across various goods, technologies, and services. They've worked on fascinating cases like evaluating the environmental impacts of different end-of-life options for junk car tyres, with a focus on pyrolysis treatments.

Pulling data both from the tech supplier and their own extensive databases, they built detailed inventories for each scenario.

They didn't stop there — SLR also used characterisation factors across 21 environmental indicators to give a clear view of each disposal method's effects. This thorough analysis highlighted how pyrolysis stacks up against other options and pinpointed the critical areas affecting outcomes.

Such insights are invaluable for making informed decisions in waste management, showing just how crucial hands-on experience is in delivering impactful LCA studies.

Examples of LCA applications and impact assessment

Life Cycle Assessments (LCAs) play a big role in environmental research and management. They help us understand the full impact of products from start to finish. Here are some ways LCAs get used:

- Deciding Between Materials: Companies use LCAs to choose materials that cause the least harm to the environment. For example, an LCA can show whether a paper bag or a plastic one has a lower carbon footprint over its lifetime.

- Improving Product Designs: Designers look at LCA data to make products more sustainable. If an LCA shows that a product uses too much water, designers might change the product to use less.

- Energy Use Analysis: LCAs help figure out how much energy products need during their life span. This can lead to finding ways to reduce energy use, like using renewable energy sources.

- Waste Management Solutions: Government bodies rely on LCAs for better waste management strategies. An LCA can reveal if it's better for the environment to recycle a product or incinerate it – to extract the energy from it.

- Setting Environmental Policies: Governments use LCA findings to set rules that protect our planet. These policies might encourage recycling or ban certain harmful materials.

- Comparing Products: Before buying, companies and consumers can look at LCAs to pick the most eco-friendly option—like choosing between two brands of light bulbs based on their environmental impact.

- Identifying ‘Hot Spots': The SLR case study showed how LCAs pinpoint parts of a product's life that hurt the environment most, known as ‘hot spots'. For scrap vehicle tires, they found pyrolysis treatment could be greener than other disposal methods.

- Marketing Eco-Friendly Products: Companies with good LCA results use this data in marketing, showing customers how green their products are.

- Supporting New Technologies: When inventing new ways to make or recycle products, innovators use LCAs to prove their technology is environmentally sound.

- Exercises in Carbon Accounting: Through assessing carbon footprints using LCAs, businesses can work towards reducing greenhouse gas emissions across all stages of their products' lives.

LCAs (Life Cycle Analysis of products) offer fresh insights into how we can live and work without harming our planet so much. From making smarter design choices to supporting greener laws, these assessments guide important decisions every day.

Authors and recent topics by Euan Munro and Becca Shaikh

Moving from the practical examples of LCA applications and their impact, we spotlight Euan Munro and Becca Shaikh. They bring a fresh perspective to sustainability efforts in the industry.

Euan leads in Energy Transition in Europe, focusing on shifting towards more sustainable energy sources. Becca works as a Process Engineer, diving into the specifics of how products are created and their environmental footprints.

They joined forces on an article titled “Inherent Sustainability: The Value of Life Cycle Assessments.” Their work shines a light on environmental evaluation across all stages of a product's life—from creation to disposal.

Through analysing scrap vehicle tyres' end-of-life options with pyrolysis treatment as an example, they provided crucial insights. This study was not just another report; it highlighted where improvements can significantly reduce environmental harm.

Through gathering data from both technology providers and SLR’s own resources, they mapped out the entire life cycle inventory for different scenarios. This approach allowed them to compare pyrolysis technology against other methods clearly showing which areas mattered most for reducing negative impacts.

Conclusion

Mastering the full life cycle assessment of a product opens up paths to smarter, greener choices. With tools like ISO standards 14040 and 14044 in your arsenal, making these assessments becomes clear-cut.

From cradle to grave—or better yet, from cradle to cradle—the journey of a product tells us how we can lessen our footprint on Earth. Through examples set by SLR's depth of experience in this field, it's obvious that sustainable strategies aren't just good for the planet; they boost stakeholder confidence too.

So here's to taking those steps towards more transparent, accountable actions—with every product's life cycle shining light on the road ahead.

Life Cycle Analysis Of A Product – FAQs

1. What exactly is a life cycle analysis of a product?

A life cycle analysis, or LCA for short, looks at every stage of a product's journey—from creation (cradle) to disposal (grave). It examines energy consumption, environmental impact, and even how it affects human health. Think of it as the story of a product's complete life.

2. Why should companies do a life cycle analysis?

Well, doing an LCA helps businesses understand their products' environmental footprint and find ways to make things more sustainable. It’s like being an eco-detective—finding clues on how to reduce global warming and be kinder to our planet.

3. Can you give me an example of what might be included in an LCA?

Sure! Let's say we're looking at a water bottle. An LCA would explore everything from the materials used (are they environmentally friendly?), the energy needed to make it (how much does that contribute to global warming?), transportation (how far does it travel?), right down to its end-of-life (can it be recycled?). Every step counts.

4. How does strategic management fit into all this?

Good question! In strategic management, using tools like the BCG matrix alongside LCA data can help companies decide where best to invest their resources—for both profit and planet. It’s about making smart choices today that won’t harm us tomorrow.

5. Is there any standard way to conduct an LCA?

Yes—there are guidelines set by ISO 14044 that offer a standardised approach for conducting LCAs. This means everyone plays by the same rules, ensuring comparisons between products are fair… like having referees in sports!

6. What’s one common myth about LCAs you’d bust if you could?

Ah, I'd tackle the belief that LCAs are only about counting carbon emissions or saving trees—it goes beyond that! They consider everything from water use and pollution risk management to how products affect people's health across their entire lifecycle…not just bits and pieces.

7. What is the scope of an LCA?

The scope of a Life Cycle Assessment (LCA) varies with each study, being tailored specifically to meet the client's objectives. This customization allows for a detailed examination of the product's environmental impact through different stages of its life.

8. What are the different approaches to conducting an LCA?

There are several approaches to conducting an LCA, each offering a different level of detail and focus. The “cradle to grave” approach encompasses all stages, from raw material extraction to final disposal.

The “cradle to cradle” method is the most thorough, examining the product's lifecycle from creation to reuse, highlighting the complete environmental impact.

For a simpler and more cost-effective analysis, the “cradle to gate” approach focuses on the product's journey from raw material extraction to the point it leaves the factory.

9. Why choose a “cradle to cradle” approach for LCA?

The “cradle to cradle” approach is chosen for its comprehensive analysis of a product's lifecycle. This method not only examines the environmental impact from the product's creation to its end of life but also considers its potential for reuse.

This approach provides a full picture of the product's environmental footprint, making it ideal for those seeking to understand and mitigate their product's impact comprehensively.

10. What are the benefits of a “cradle to gate” LCA approach?

A “cradle to gate” LCA approach offers a simpler and more cost-effective way to assess a product's environmental impact.

By focusing on the product's journey from raw material extraction to the point it leaves the factory, this method allows for a focused examination of the most controllable parts of the product's lifecycle.

It is particularly beneficial for manufacturers and designers looking to improve the sustainability of their production processes.