Read about our list of five modern technologies that reduce dependence on landfills by improving waste collection, sorting, and processing. These innovations divert waste through increased recycling and energy recovery, advancing the transition toward a circular economy.

Technologies Reducing Landfill Dependence – The Key Takeaways

- Plasma gasification can convert nearly any waste material into clean energy while producing almost zero emissions compared to conventional waste management methods.

- AI-powered sorting systems have increased recycling recovery rates by up to 90% in some facilities, dramatically reducing landfill inputs.

- Chemical recycling technologies are now able to process previously “unrecyclable” plastics like food packaging and multilayer materials.

- Organic waste conversion through advanced composting and anaerobic digestion can divert up to 30% of landfill-bound waste.

- Innovative biodegradable packaging solutions are creating truly circular alternatives that leave zero waste.

Our landfills are reaching critical capacity. With over 2 billion tons of municipal solid waste generated annually worldwide, finding innovative alternatives isn't just smart—it's essential for our planet's future.

The good news? Revolutionary technologies are emerging that not only reduce landfill dependence but also transform waste into valuable resources. EcoTech Solutions has been at the forefront of developing these waste reduction technologies, helping communities transition to more sustainable waste management practices.

The Waste Crisis: Why We Need Landfill Alternatives Now

Traditional landfills pose serious environmental threats—greenhouse gas emissions, groundwater contamination, and the permanent loss of resources. What's worse, we're running out of space. In many regions, landfills are projected to reach capacity within the next decade, creating an urgent need for alternative solutions.

Beyond the environmental impact, the economic costs are staggering. Municipalities spend billions annually on waste management, while valuable resources literally get buried. The linear “take-make-dispose” model is proving unsustainable in both ecological and economic terms.

The good news is that technological innovation is accelerating rapidly. The five technologies explored below aren't just conceptual—they're being implemented today, creating pathways to dramatically reduce our landfill dependence while recovering energy and materials that would otherwise be lost.

1. Plasma Gasification: Turning Trash into Clean Energy

Plasma gasification represents one of the most promising alternatives to traditional landfills. Unlike conventional incineration, this technology uses extreme temperatures (up to 10,000°F) to convert waste into a synthetic gas that can generate electricity or be transformed into liquid fuels. The process breaks down virtually any waste—including hazardous materials—at the molecular level. For more on how this technology is transforming waste disposal, check out these cutting-edge innovations in the field.

“Plasma Gasification | netl.doe.gov” from netl.doe.gov and used with no modifications.

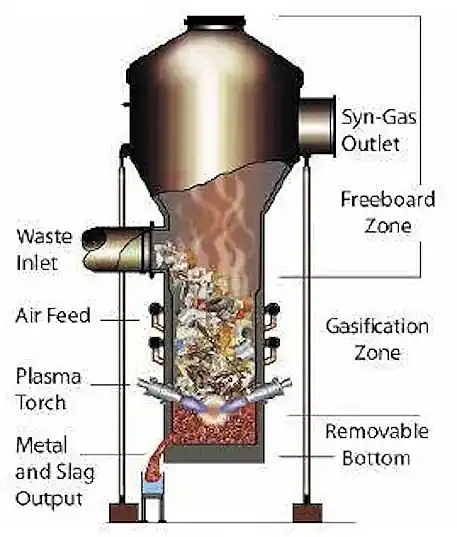

How Plasma Gasification Works

At the heart of plasma gasification are plasma torches that create an electrical arc, similar to lightning, that turns air into plasma—a state of matter where electrons separate from atoms. This intensely hot plasma field breaks down waste into its basic elements. The organic components are converted to syngas (primarily hydrogen and carbon monoxide), while inorganic materials melt into a glass-like substance called slag, which can be used in construction materials.

What makes this technology revolutionary is its ability to process mixed waste streams without extensive pre-sorting. Municipal solid waste, medical waste, and even hazardous materials can all be processed through the same system, eliminating the need for separate waste management streams.

“Landfill Waste: What Can We Do to …” from earth.org and used with no modifications.

Environmental Benefits Over Traditional Incineration

- Near-zero emissions of dioxins, furans, and other harmful pollutants

- 95-99% reduction in waste volume compared to landfilling

- Production of clean energy that can offset fossil fuel consumption

- Elimination of methane emissions associated with landfills

- Recovery of metals and minerals that would otherwise be buried

Real-World Gasification Success Stories

In Utashinai, Japan, a commercial-scale plasma gasification facility has been processing municipal solid waste and auto shredder residue since 2002. The facility processes up to 300 tons of waste daily while generating enough electricity to power thousands of homes. Similar facilities are now operating or under construction in China, the UK, and Canada, demonstrating the commercial viability of this technology at scale.

2. AI-Powered Sorting Systems: Making Recycling Smarter

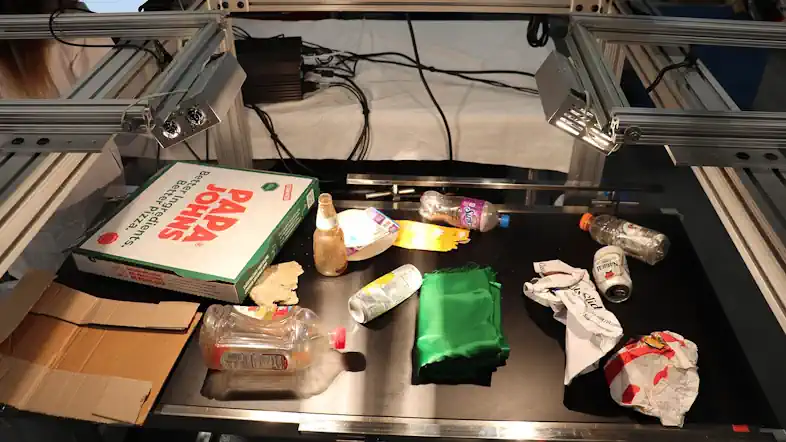

Conventional recycling facilities face a fundamental challenge: contamination. When non-recyclable items enter the recycling stream, they can render entire batches unusable. This is where artificial intelligence is revolutionizing the industry, with smart sorting systems that can identify and separate materials with unprecedented accuracy and speed. Learn more about the risks and solutions of waste management.

Machine Learning for Material Recognition

Modern AI-powered sorting systems combine high-resolution cameras, infrared sensors, and sophisticated machine learning algorithms to identify materials based on their visual and physical properties. These systems can distinguish between different types of plastics, metals, paper, and contaminants at speeds far exceeding human capacity. As these systems process more materials, they continuously improve through machine learning, adapting to new packaging types and material combinations.

The technology has advanced to the point where AI sorters can now recognize subtle differences between similar-looking materials – like PET and PVC plastics – that would be nearly impossible for human sorters to differentiate at high speeds. Some systems can even identify food residue or other contaminants on otherwise recyclable materials.

“AI-Powered Waste Management System to …” from sustainability.ncsu.edu and used with no modifications.

Increased Recovery Rates vs. Manual Sorting

The impact of AI-powered sorting on recycling efficiency is dramatic. Traditional manual sorting typically achieves recovery rates of 30-70%, with significant human error and limited throughput. In contrast, advanced AI systems consistently achieve 90-95% accuracy while processing materials at rates up to 3,000 items per minute – roughly ten times faster than manual sorting. Discover more about innovative technologies driving zero waste initiatives.

Beyond speed and accuracy, these systems can operate 24/7 without fatigue, dramatically increasing the total volume of materials that can be recovered. Facilities that have implemented AI sorting report 25-50% increases in overall material recovery and substantial reductions in the amount of recyclable material erroneously sent to landfills.

Cost Benefits for Municipalities and Businesses

- Reduced labor costs and improved worker safety by automating dangerous sorting tasks

- Higher-value recycled materials due to improved purity of sorted streams

- Lower contamination rates leading to fewer rejected loads

- Decreased landfill tipping fees through improved diversion rates

- Adaptability to changing waste streams without major system redesigns

Real-World AI-Powered Sorting Success Stories

Denver, Colorado's recycling facility, implemented an AI-powered sorting system in 2019 that increased their recovery rate by 35% while reducing operating costs by nearly $1 million annually. The system uses optical sorters and robotic arms guided by machine learning algorithms to identify and separate recyclables at high speed. Similar systems in Barcelona, Spain, and Melbourne, Australia, have demonstrated comparable results, confirming that this technology delivers consistent benefits across different waste streams and regional contexts.

“AMP Robotics' new AI-enabled compact …” from www.recyclingproductnews.com and used with no modifications.

3. Chemical Recycling: Breaking Down Plastics That Traditional Methods Can't

For decades, certain types of plastics have been considered practically unrecyclable through conventional mechanical methods. Multi-layer films, colored plastics, and contaminated materials typically end up in landfills despite their inherent value. Chemical recycling is changing this paradigm by breaking polymers down to their molecular building blocks, enabling truly circular plastics economy.

The Science Behind Depolymerization

“Circular Plastics System …” from pubs.acs.org and used with no modifications.

Chemical recycling encompasses several technologies that break down polymer chains into their original monomers or other valuable hydrocarbon products. The most promising approaches include pyrolysis, which uses heat in the absence of oxygen to convert plastics into oils and gases; solvolysis, which uses solvents to dissolve specific polymers; and enzymatic processes that employ engineered enzymes to break specific chemical bonds in plastics. Unlike mechanical recycling, which merely reshapes materials, chemical recycling actually transforms them at the molecular level, eliminating accumulated contaminants and additives.

These processes effectively “reset” the plastic to its virgin state, allowing for infinite recycling without the quality degradation typically seen in conventional recycling. This breakthrough addresses one of the most significant barriers to plastic circularity – the fact that most plastics can only be mechanically recycled a few times before becoming unusable. For more insights on waste management, check out this waste management guide.

Types of Plastics Now Recyclable

Chemical recycling has dramatically expanded the range of plastics that can enter the circular economy. Food-contaminated packaging, multi-layer films used for food preservation, colored plastics, and composite materials containing multiple polymer types can now be processed effectively. Even expanded polystyrene (Styrofoam), previously considered a recycling nightmare, can be broken down into its styrene components and remanufactured into new products.

From Waste to Raw Materials: The Circular Loop

Perhaps the most exciting aspect of chemical recycling is its potential to create true circularity in the plastics industry. Rather than downcycling plastic into lower-value products, these technologies can produce feedstocks identical to those derived from virgin petroleum. Major chemical companies like BASF, Dow, and LyondellBasell are already incorporating chemically recycled content into their production of new plastics, creating products that are indistinguishable from those made with conventional feedstocks.

This closed-loop system is rapidly scaling up. In Europe alone, chemical recycling capacity is projected to increase from approximately 500,000 tons in 2022 to over 3 million tons by 2030. As these technologies mature and economies of scale develop, the cost of chemically recycled materials is expected to become competitive with virgin plastics, especially as carbon taxes and extended producer responsibility regulations come into effect globally.

4. Organic Waste Conversion Technologies

Organic waste—food scraps, yard trimmings, and agricultural residues—constitutes roughly 30-40% of municipal solid waste in most countries. When sent to landfills, these materials decompose anaerobically, producing methane, a greenhouse gas 25 times more potent than carbon dioxide. Innovative organic waste conversion technologies are now providing sustainable alternatives while producing valuable byproducts.

Advanced Composting Systems

Traditional composting has evolved dramatically with the introduction of in-vessel systems that accelerate decomposition while controlling odors and emissions. These enclosed systems precisely manage temperature, moisture, and aeration, reducing the composting process from months to weeks while producing a consistent, high-quality soil amendment. Advanced sensors and automation allow these systems to operate with minimal human intervention while maximizing the conversion of organic waste into usable compost.

For urban environments, modular composting systems now enable on-site processing at restaurants, grocery stores, and apartment complexes, eliminating transportation emissions and creating hyperlocal nutrient recycling. Some innovative systems even incorporate heat recovery, capturing the thermal energy generated during composting for space heating or hot water production. Learn more about how to recycle organic waste effectively.

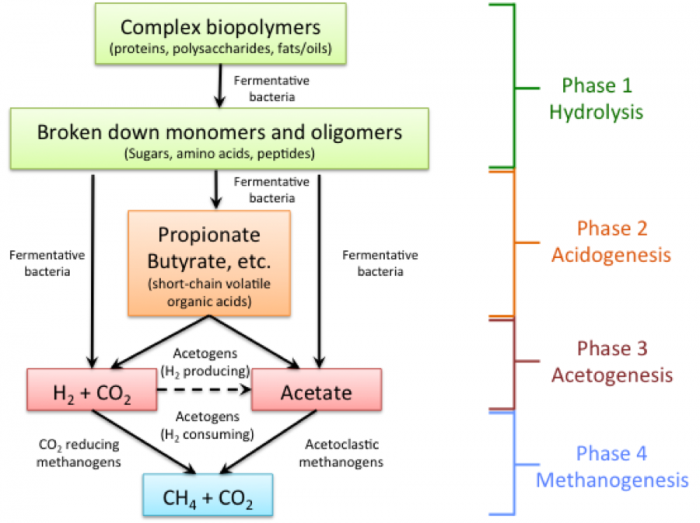

Anaerobic Digestion for Biogas Production

Anaerobic digestion harnesses microorganisms to break down organic materials in oxygen-free environments, producing biogas (a mixture of methane and carbon dioxide) that can be used for electricity generation, heating, or as renewable natural gas for vehicles. Modern digesters can process mixed organic waste streams, including food waste, agricultural residues, and even certain types of paper products, making them incredibly versatile waste management solutions.

The technology has seen significant advancements in recent years, with new pre-treatment methods that increase biogas yields and sophisticated purification systems that produce biomethane indistinguishable from conventional natural gas. In Sweden, purified biogas now fuels much of the public transportation system, demonstrating the potential for waste-derived energy to replace fossil fuels in real-world applications.

“11.1 Anaerobic Digestion | EGEE 439 …” from courses.ems.psu.edu and used with no modifications.

Black Soldier Fly Larvae: Nature's Waste Processors

One of the most intriguing developments in organic waste management is the commercial-scale use of black soldier fly larvae (BSFL) to process food waste. These remarkable insects can consume twice their body weight daily in almost any type of food waste, converting it into valuable protein (themselves) and a nutrient-rich soil amendment (their excrement). The larvae can then be harvested and processed into high-quality animal feed or even human food ingredients, creating a direct pathway from waste to nutrition.

BSFL processing facilities require minimal energy input compared to other waste management technologies and can operate effectively at various scales, from household systems to industrial facilities. Companies in North America, Europe, and Asia are now operating commercial BSFL facilities that can process tons of food waste daily while producing protein meal that sells for premium prices in animal feed markets.

From Food Waste to Sustainable Products

- Bioplastics derived from food waste are now being used for packaging and disposable items

- Citrus peels are being transformed into cleaning products and textile dyes

- Coffee grounds are finding new life as mushroom growing substrate and biofuels

- Brewery waste is being converted into animal feed, bread products, and energy

- Nutshells and fruit pits are becoming activated carbon for water filtration

Community-Scale Implementation

What makes organic waste conversion particularly promising is its scalability. While large centralized facilities offer efficiency advantages, smaller community-scale systems have proven effective in diverse settings from urban neighborhoods to rural villages. In Seoul, South Korea, neighborhood-level anaerobic digesters process food waste from surrounding households, generating biogas that powers local facilities while producing liquid fertilizer distributed back to residents for urban gardening.

Similar community-scale implementations in Milan, Italy, and Portland, Oregon, have demonstrated that decentralized organic waste management can achieve high participation rates while creating local jobs and reducing transportation emissions. These systems often become community focal points, raising awareness about waste issues and inspiring broader sustainability initiatives.

5. Biodegradable Packaging Innovations

Packaging waste constitutes approximately one-third of municipal solid waste and poses particular challenges for recycling due to contamination, multi-material construction, and small format items. Revolutionary biodegradable packaging innovations are addressing these challenges by creating materials designed to safely return to natural cycles rather than persisting in the environment.

“6 ECO-FRIENDLY ALTERNATIVES TO PLASTIC …” from www.packmile.com and used with no modifications.

Plant-Based Alternatives to Plastic

Biopolymers derived from plant sources like cornstarch, sugarcane, and cellulose are now being engineered to match the performance characteristics of conventional plastics while biodegrading completely in composting environments. These materials have advanced significantly in recent years, with improved moisture barriers, temperature resistance, and mechanical properties that make them suitable for food packaging and other demanding applications. Unlike many early bioplastics that required industrial composting facilities, newer materials can break down in home composting systems or even in marine environments, providing end-of-life options even where formal waste management infrastructure is limited.

Companies like Footprint and Notpla are commercializing plant-based packaging that performs like plastic but decomposes like food waste. Major brands including Nestlé, Unilever, and PepsiCo have begun transitioning product lines to these materials, signaling a fundamental shift in how packaging is designed and managed after use.

Mushroom Packaging: Growing Your Own Containers

Perhaps the most radical packaging innovation comes from companies using mycelium—the root structure of mushrooms—to grow custom packaging materials. This process combines agricultural waste like corn husks or hemp stalks with mycelium in molds where the fungal network grows to bind the material together. After a few days, the resulting structure is dried to stop growth, creating a packaging material that provides excellent cushioning and insulation while being fully home compostable. Discover more ideas for reducing your own waste and saving money.

Unlike conventional foam packaging that persists for centuries, mycelium packaging breaks down in backyard compost piles within 45-90 days, returning nutrients to soil. IKEA, Dell, and Moet Hennessy are among the major companies now using mycelium packaging for shipping products, demonstrating its commercial viability as a replacement for styrofoam and other difficult-to-recycle materials.

Water-Soluble Films and Wrappers

For applications where complete dissolvability is advantageous, water-soluble polymers like polyvinyl alcohol (PVA) are enabling innovative packaging solutions. These materials completely dissolve in water, leaving no microplastics behind. While PVA has been used for laundry pods and dishwasher tablets for years, newer applications include food packaging, agricultural films, and even textiles that can be safely disposed of in wastewater systems. These materials are particularly promising for single-dose products and applications where recycling would be impractical due to contamination or small format.

Taking Action: How You Can Support These Technologies

The transition away from landfill-dependent waste management requires action at multiple levels. While these technologies represent promising solutions, their widespread adoption depends on supportive policies, informed consumer choices, and community engagement. Individuals have significant power to accelerate this transition through their daily decisions and civic participation. Learn more about what happens to rubbish in landfill to understand the importance of these actions.

By making conscious consumption choices and advocating for systemic change, individuals can create the market conditions and policy environment needed for these technologies to scale rapidly. The actions outlined below represent practical steps anyone can take to support landfill reduction innovations.

Consumer Choices That Drive Change

Every purchase decision sends signals to manufacturers and retailers about consumer preferences. Prioritizing products with minimal packaging, selecting items in recyclable or compostable materials, and supporting brands that incorporate recycled content all help create demand for circular solutions. Equally important is participating in proper waste sorting at home—contamination in recycling and compost streams remains one of the biggest barriers to effective resource recovery. Taking the time to learn local recycling guidelines and properly preparing materials for collection directly impacts the viability of advanced recycling technologies.

Community Advocacy for Better Waste Systems

Local waste management decisions have enormous impact on landfill diversion rates. Attending city council meetings, participating in waste management planning processes, and organizing neighborhood education campaigns can all help accelerate the adoption of innovative technologies. Many communities have successfully implemented pilot programs for food waste collection, advanced recycling, or even community-scale biogas generation after sustained advocacy from residents.

Collective action is particularly effective in this space—forming or joining local sustainability groups multiplies individual impact and creates visible community support for waste reduction initiatives. These groups can organize collection events for hard-to-recycle items, coordinate with local businesses on waste reduction efforts, and build political will for infrastructure investments in advanced waste technologies.

Supporting Policies That Promote Innovation

Policy frameworks profoundly influence waste management outcomes. Extended producer responsibility (EPR) regulations, landfill taxes, organic waste bans, and procurement requirements for recycled content all create economic incentives for landfill alternatives. Contacting elected representatives, supporting environmental organizations focused on waste policy, and voting for candidates who prioritize sustainable materials management all help create the regulatory environment needed for these technologies to thrive. In many regions, the policy landscape is currently undergoing significant reform, making this an especially impactful time for citizen engagement on waste issues.

Public-private partnerships have proven particularly effective for scaling new waste technologies. Supporting bond measures or tax initiatives that fund innovative waste infrastructure represents a direct way to accelerate the transition to more sustainable waste management systems in your community.

Frequently Asked Questions

As these technologies continue to develop and scale, many questions arise about their implementation, effectiveness, and accessibility. The following addresses some of the most common inquiries about innovative landfill reduction technologies.

How much waste do we currently send to landfills globally?

Globally, approximately 2 billion tons of municipal solid waste is generated annually, with projections suggesting this will increase to 3.4 billion tons by 2050 if current trends continue. The percentage sent to landfills varies dramatically by region—from less than 10% in countries like Sweden, Germany, and Japan, to over 90% in many developing nations. In the United States, despite having only 4% of the global population, about 292 million tons of municipal waste is generated annually, with roughly 50% ending up in landfills.

The composition of landfilled waste also varies significantly, but organic materials (food waste and yard trimmings) typically constitute 30-40% of the total, with paper and cardboard (15-20%), plastics (10-15%), and various other materials making up the remainder. The World Bank estimates that at least 33% of all waste globally is not managed in an environmentally safe manner, highlighting the urgent need for improved waste management systems.

What's particularly concerning is that landfill space is rapidly diminishing in many regions, with major metropolitan areas facing severe capacity constraints within the next 5-10 years. This capacity crisis is driving both increased interest in landfill alternatives and, unfortunately, the export of waste to regions with weaker environmental regulations.

Are these technologies affordable for smaller communities?

While many advanced waste technologies benefit from economies of scale, modular versions of most systems are becoming increasingly available for smaller communities. Anaerobic digesters, for instance, now come in containerized units that can process as little as 1-5 tons of organic waste daily, making them suitable for small towns or even large institutional settings like universities or hospital complexes. Similarly, AI-assisted recycling systems are now available in various scales, with entry-level optical sorters becoming accessible for smaller material recovery facilities. The key for smaller communities is often regional cooperation—sharing infrastructure costs across multiple municipalities can make advanced technologies economically viable even in less populated areas.

How soon could these technologies replace traditional landfills?

The timeline for transitioning away from landfill dependence varies by technology, region, and waste stream. For organic waste, which constitutes 30-40% of municipal solid waste, alternatives like composting and anaerobic digestion are already commercially viable and rapidly scaling. Many regions have implemented organic waste bans that will eliminate food waste from landfills within 5-10 years. For recyclable materials, advanced sorting technologies are being deployed now, with widespread implementation expected within the next decade. The most challenging waste streams—including mixed plastics and certain complex materials—will likely take 15-20 years to fully divert from landfills, though significant progress is expected much sooner. Countries like Finland, Austria, and the Netherlands have already achieved landfill diversion rates exceeding 90%, demonstrating that near-zero landfill scenarios are achievable with current technology when supported by appropriate policy frameworks.

What can I do at home to reduce my landfill contribution?

Individual action remains powerful in reducing landfill impact. The most effective steps include composting food scraps (either at home or through municipal collection), properly sorting recyclables according to local guidelines, and most importantly, reducing consumption of single-use items. Purchasing durable goods, repairing rather than replacing products, and choosing items with minimal packaging all significantly reduce waste generation. Many communities now offer specialized collection programs for hard-to-recycle items like electronics, textiles, and household hazardous waste, which keep these problematic materials out of landfills. Apps like Recycle Coach and Earth911 can help identify local options for responsibly managing specific waste streams.

Beyond individual actions, encouraging workplace waste reduction, supporting package-free stores, and advocating for school composting programs helps create the cultural shift needed to support broader waste reduction efforts. Every pound of waste diverted or prevented represents resources conserved and pollution avoided.

Do these technologies create harmful emissions or byproducts?

Modern waste conversion technologies are engineered to minimize environmental impacts, with emissions typically far lower than both landfilling and older waste management approaches. Plasma gasification, for instance, operates at temperatures high enough to completely break down potential pollutants, with emissions generally cleaner than natural gas power plants. Advanced anaerobic digestion systems capture all generated biogas for beneficial use, preventing the methane emissions that would occur if the same materials decomposed in landfills. Chemical recycling technologies employ closed-loop systems that capture and reuse solvents and other process chemicals, minimizing releases to the environment.

That said, proper operation and monitoring remain essential. All waste conversion systems require appropriate emissions controls and regular testing to ensure performance meets or exceeds regulatory standards. The environmental benefits of these technologies are maximized when they're part of a comprehensive waste management strategy that prioritizes reduction and reuse before processing. When implemented correctly, these innovative approaches offer dramatic environmental improvements over landfill disposal while recovering valuable materials and energy.