Seafood shell waste, which is generally a by-product of the seafood industry, can be recycled into an expanding range of useful products and applications, instead of being discarded as waste. In addition to using shells for construction, this now includes: a soil amendment, or extracting valuable compounds like chitin for biodegradable packaging, medical, and other uses.

Seafood Shell Waste Recycling: Key Takeaways

- The seafood industry generates approximately 7 million tons of shell waste annually, creating both environmental challenges and business opportunities in the circular economy.

- Seafood shells contain valuable compounds like calcium carbonate and chitin that can be transformed into products for agriculture, construction, pharmaceuticals, and more.

- Companies like Shellworks and Blue Circle Foods are already profiting from shell waste recycling while reducing landfill waste and environmental impact.

- Starting a shell recycling business requires identifying reliable waste sources, selecting appropriate processing technology, and understanding market demands.

- Regulatory pressures on food waste management are increasing globally, creating urgency for innovative shell waste solutions and opening doors for sustainable entrepreneurs.

The $7 Million Ton Problem: Why Seafood Shell Waste Matters Now

Every year, the global seafood industry discards approximately 7 million tons of shell waste (2022 figures). That's roughly the weight of 700 Eiffel Towers tossed into landfills or dumped into oceans annually and it seems a low estimate compared with the 31.6 Million Tons of seafood consumed globally each year. For entrepreneurs with vision, this massive waste stream represents not just an environmental challenge, but an untapped goldmine of opportunity in the circular economy.

The timing couldn't be better for innovative business solutions in seafood shell waste recycling. As seafood consumption continues to rise globally—with annual per capita consumption now exceeding 20kg—so does the mountain of discarded shells from processing plants, restaurants, and food service operations. What many see as garbage, forward-thinking entrepreneurs recognize as valuable raw materials waiting to be transformed.

Shell waste recycling sits at the intersection of multiple business trends: sustainable materials innovation, waste-to-value processing, circular economy models, and increasing regulatory pressure on food waste. Companies that can efficiently collect, process, and transform these materials stand to benefit from both the economic value of their products and the sustainability credentials increasingly demanded by consumers and investors alike.

“The Perfect Seafood Platter Recipe …” from bellyrumbles.com and used with no modifications to illustrate just how much ends up as seafood shell waste.

Environmental Impact of Discarded Shells in Landfills

When seafood shells decompose in landfills, they generate methane—a greenhouse gas 25 times more potent than carbon dioxide. Beyond the climate impact, this waste of valuable biological materials represents a missed opportunity for carbon sequestration. Shells naturally contain calcium carbonate that took years to form and could continue serving valuable purposes rather than creating environmental problems. Additionally, the transportation and disposal of these heavy materials consume significant energy and landfill space, creating unnecessary carbon emissions and infrastructure burdens in waste management systems.

Untapped Value: Calcium Carbonate and Chitin Resources

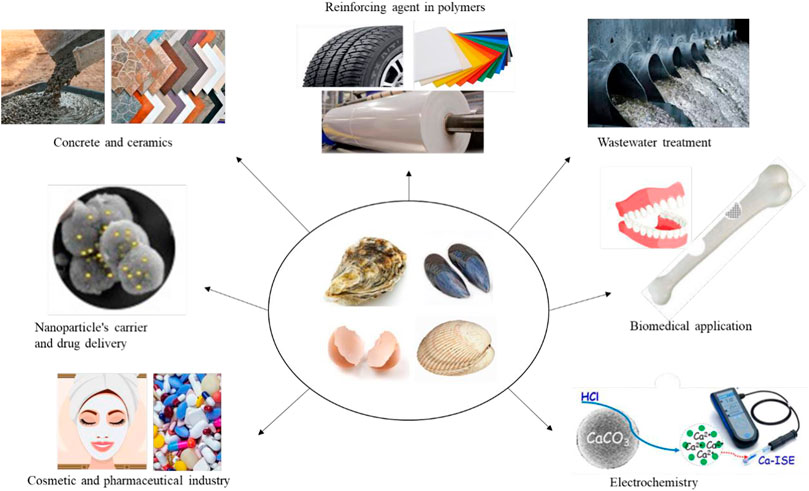

Seafood shells are treasure troves of valuable compounds. Crab, lobster, and shrimp shells contain chitin—a versatile biopolymer used in everything from surgical sutures to agricultural pesticides. Meanwhile, mollusc shells like oysters and mussels are approximately 95% calcium carbonate, a compound with applications ranging from soil amendments to pharmaceuticals.

These natural materials, when properly processed, can replace synthetic alternatives in numerous industrial applications. “Reusing shell waste is a perfect example of a circular economy, particularly as shells are a valuable biomaterial,” notes James Morris, a researcher with Calcium in a Changing Environment.

“discarded seashells …” from designwanted.com and used with no modifications.

Growing Regulatory Pressure on Food Processing Waste

Seafood shell waste recycling is a form of food processing waste. Regulatory frameworks around food processing waste are tightening globally. The European Union's Circular Economy Action Plan explicitly targets food waste streams for recovery and valorization, while municipalities across North America and the EU nations are increasingly restricting organic waste in landfills.

In Asia, countries like Japan have pioneered shell waste recycling to reduce landfill pressures. These regulatory shifts create both urgency and opportunity for businesses that can offer compliant, cost-effective shell waste management solutions.

Early movers in the seafood shell waste space gain advantages in developing infrastructure, expertise, and market positioning before compliance becomes mandatory. Learn more about the top reasons for recycling and how it impacts regulatory policies.

Proven Circular Economy Solutions for Shell Waste

The circular economy offers a framework for rethinking how we utilize resources, designing waste out of our systems, and keeping materials in productive use. Seafood shells represent a perfect candidate for circular thinking—they're abundant, consistent in composition, and can be transformed into multiple value streams through different processing methods.

Entrepreneurs exploring this space should consider the full spectrum of potential applications, as different shell types and processing methods yield diverse end products with varying market values and investment requirements.

From low-tech crushing operations producing agricultural lime to sophisticated extraction facilities isolating pharmaceutical-grade chitin using techniques such as fermentation, the options span a wide range of technical complexity and capital requirements. For those interested in recycling initiatives, understanding the top reasons for recycling can provide valuable insights into market potential and sustainability benefits.

Shell-to-Soil: Agricultural Applications

Perhaps the most accessible entry point into shell recycling is in agricultural applications of seafood shell waste. Crushed oysters, mussels, and clam shells provide an excellent source of calcium for soil amendment, particularly in acidic soils where they help neutralize pH while slowly releasing nutrients. The natural, slow-release profile of shell-derived calcium makes it particularly valuable for organic farming operations seeking alternatives to synthetic fertilizers.

Shell meal can also be incorporated into poultry feed as a calcium supplement for egg-laying hens, replacing mined limestone with a renewable alternative. This application requires minimal processing—typically just cleaning, drying, and grinding—making it accessible for entrepreneurs with limited capital.

Several regional operations in coastal areas have built profitable businesses supplying local farms with shell-derived soil amendments and animal feed supplements.

![]()

“oyster shell derived biochar …” from www.sciencedirect.com and used with no modifications, is just one example of seafood shell waste recycling.

Construction Materials and Building Products

The construction industry's growing interest in sustainable materials has opened new avenues for shell waste valorization. Crushed shells can replace traditional aggregates in concrete formulations, reducing the need for mining while creating a carbon-sequestering building material. Innovative companies like Green Blue Building Materials have developed shell-based alternatives to conventional cement products, claiming up to 40% reduction in carbon footprint compared to traditional options.

Shell-based construction materials offer more than just environmental benefits—they also provide superior performance characteristics in certain applications. Oyster shell concrete, for instance, demonstrates excellent compressive strength and durability in marine environments due to its natural resistance to saltwater degradation. This value-added performance allows sustainable entrepreneurs to command premium pricing in specialised construction markets rather than competing solely on cost.

From decorative terrazzo flooring featuring visible shell fragments to structural building panels incorporating shell powder, the applications for seafood shell waste continue to expand as research advances. The construction sector represents a high-volume potential market that could absorb significant quantities of processed shell waste, making it attractive for scaling operations.

Water Filtration and Purification Systems

Calcium-rich shells demonstrate remarkable properties for water filtration and purification applications. Crushed oyster and mussel shells effectively remove phosphates, heavy metals, and certain organic contaminants from wastewater streams. These natural filtration media can replace manufactured alternatives in both municipal and industrial water treatment systems, often with comparable or superior performance.

Several wastewater treatment facilities have implemented shell-based filtration systems that not only improve water quality but reduce operational costs compared to synthetic media. The material's natural porosity and surface chemistry create ideal conditions for beneficial bacterial growth, enhancing biological filtration processes in constructed wetlands and biofiltration units. Additionally, spent shell media can often be repurposed as agricultural lime after its filtration lifecycle, creating a truly circular material flow.

“We've found that properly processed oyster shell media outperforms conventional limestone in phosphorus removal by approximately 35%, while simultaneously buffering pH and supporting beneficial microbial communities in our filtration systems.” – Water Treatment Facility Manager, Pacific Northwest

![]()

“Water purification by oyster shell bio …” from www.sciencedirect.com and used with no modifications, as an example of seafood shell waste recycling.

Pharmaceutical and Cosmetic Ingredients

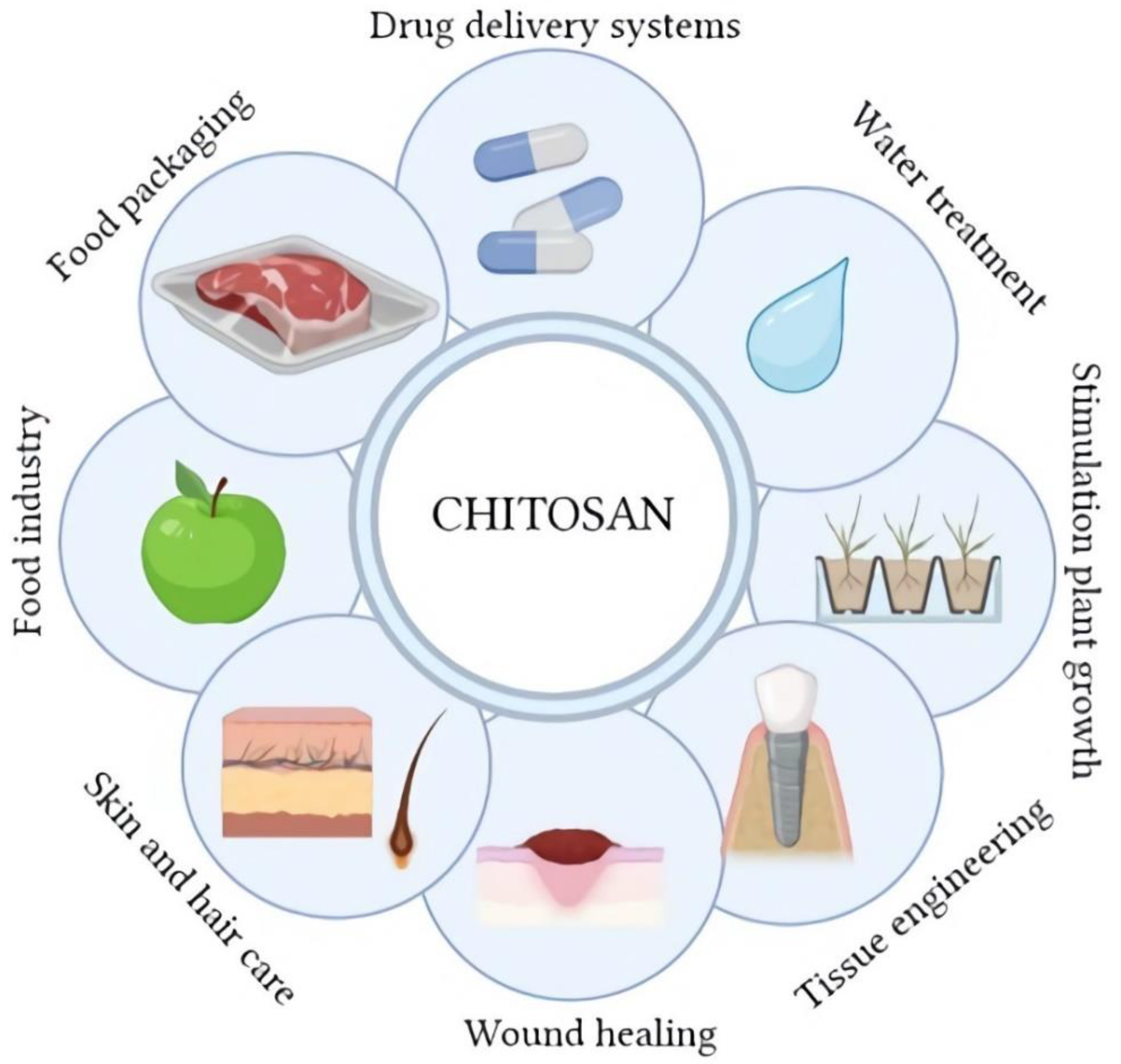

The highest value-added applications for shell waste may lie in pharmaceutical and cosmetic ingredients derived from chitin. This natural polymer, abundant in crustacean shells, can be processed into chitosan—a versatile compound used in everything from wound dressings and surgical sutures to anti-aging skincare products. The global chitosan market exceeds $1.7 billion annually and continues to grow as new applications emerge in medicine, cosmetics, and food technology.

While extraction of pharmaceutical-grade chitin requires more sophisticated processing technology than simpler applications, the potential returns justify the investment for ventures with access to appropriate funding and expertise. Several biotechnology start-ups have successfully commercialized proprietary extraction processes that yield high-purity chitin derivatives from seafood processing waste, commanding premium prices from pharmaceutical and cosmetic manufacturers.

“Chitosan Based Materials in Cosmetic …” from www.mdpi.com and used with no modifications. Tgis shows the versatility of

Biodegradable Packaging Alternatives

As plastic pollution concerns drive demand for sustainable packaging, shell-derived materials offer promising alternatives. UK-based Shellworks has developed a proprietary process for transforming discarded shellfish shells into biodegradable packaging materials that perform similarly to conventional plastics but decompose naturally after use. Their innovation addresses dual environmental challenges—reducing both plastic pollution and shell waste—while creating premium products for eco-conscious brands.

The biodegradable packaging market is projected to grow at 17% CAGR through 2026, creating expanding opportunities for shell-based alternatives. From food service containers to protective packaging materials, applications continue to diversify as material science advances. For entrepreneurs with backgrounds in materials engineering or polymer science, this high-growth sector offers particularly attractive entry points into the shell waste circular economy.

Success Stories: Companies Transforming Shell Waste

The theoretical potential of shell recycling is being proven through successful commercial implementations across multiple sectors. These pioneers demonstrate viable business models that combine environmental benefits with financial sustainability, providing valuable blueprints for new entrants in the space.

Shellworks: From Shells to Sustainable Packaging

Shellworks exemplifies the innovative potential in high-value applications for shell waste. This London-based startup transforms crustacean shells into a versatile bioplastic material through their proprietary extraction and formulation process. Their products include biodegradable cosmetic packaging, food service items, and protective mailers that decompose naturally at end-of-life, leaving no microplastic residues.

What distinguishes Shellworks' approach to seafood shell waste is their focus on premium markets willing to pay for truly sustainable solutions. By partnering with luxury brands concerned about plastic packaging's environmental impact, they've positioned their shell-derived materials as premium alternatives rather than competing directly with commodity plastics on price. This strategy has allowed them to scale gradually while maintaining healthy margins, attracting investment from sustainability-focused venture funds.

“Transforming Sustainable Packaging with …” from www.materialfuture.com and used with no modifications. Shows how this biodegradable plastic, made from seafood shell waste, degrades over just a few weeks in a commercial composting plant.

Blue Circle Foods: Oyster Shell Calcium Supplements

Blue Circle Foods demonstrates how established seafood companies can integrate shell recycling into existing operations to create additional revenue streams. This US-based seafood supplier has developed a vertical integration model that transforms their oyster shell waste into calcium supplements for agricultural applications. By processing shells that would otherwise incur disposal costs, they've converted a liability into a profitable product line while strengthening their sustainability credentials with consumers and retail partners.

Their success highlights the advantage of starting with guaranteed waste streams from internal operations. By controlling both supply and processing, Blue Circle has achieved consistent product quality and reliable production volumes—key factors in building trust with agricultural customers who depend on consistent inputs for their operations. For those interested in sustainable practices, exploring zero waste disposal methods can provide additional insights into maintaining consistent and environmentally friendly operations.

“Major Oyster Shell Calcium 500 mg …” from www.amazon.com and used with no modifications.

Royal Belgian Institute's Innovative Shell Processing

The Royal Belgian Institute of Natural Sciences has pioneered a comprehensive shell waste valorization system that processes mussel shells from Belgium's substantial seafood industry. Their approach is notable for its multi-product strategy, extracting multiple value streams from a single waste source. The primary process separates calcium carbonate for agricultural applications while secondary processes extract organic compounds for specialized industrial uses.

What makes their model particularly interesting is the public-private partnership structure that funded the initial infrastructure development. By combining government research funding with industry investment from seafood processors, they created a financially sustainable operation that serves both environmental and economic objectives. This collaborative approach reduced capital requirements for all stakeholders while ensuring sufficient scale for operational efficiency.

Technical Challenges in Shell Recycling

While the business opportunities in shell recycling are compelling, entrepreneurs must navigate several technical challenges to build viable operations. Understanding these challenges early in the planning process helps avoid costly mistakes and unrealistic expectations about timelines and capital requirements. Most successful ventures start with simpler processing methods and lower-value products before gradually advancing to more complex, higher-value applications as they build expertise and capital.

Processing and Sanitizing Requirements

Raw seafood shells contain organic residues that can decompose and create odour, contamination, and quality control issues. Effective sanitization processes are essential before shells can be transformed into value-added products. Most operations employ a combination of washing, heat treatment, and drying to prepare shells for further processing. The energy requirements for these steps can significantly impact operational costs, making energy-efficient equipment and potentially renewable energy sources important considerations in facility design.

Different end products require different levels of processing purity. Agricultural applications may tolerate minor organic residues, while pharmaceutical-grade inputs require exceptionally clean, consistent raw materials. Your target market will determine the level of processing sophistication needed, which directly impacts both capital and operational expenses.

Logistics and Collection Infrastructure

Perhaps the most challenging aspect of shell recycling is establishing an efficient collection infrastructure. Shells are heavy, bulky, and distributed across many generation points—from seafood processors to restaurants and food service operations. Creating cost-effective reverse logistics systems to aggregate sufficient volumes is critical to achieving operational scale.

Successful collection models typically involve strategic partnerships with waste management companies, seafood processors, or restaurant associations. Some ventures have implemented collection fees that offset transportation costs, while others provide incentives like reduced waste disposal costs to encourage participation. The most effective systems often incorporate shell collection into existing waste management routes to minimize dedicated transportation costs.

Scale-Up Barriers to New Technologies

Innovative processing technologies often work beautifully in laboratory settings but encounter unforeseen challenges when scaled to commercial volumes. Issues like equipment fouling, inconsistent product quality, and unexpected energy requirements can derail otherwise promising ventures. Pilot testing at intermediate scales is essential before committing to full commercial implementation.

Many successful shell recycling ventures have followed a phased approach to technology deployment—starting with simple mechanical processing before adding more sophisticated chemical or biological processes as volumes and revenues increase. This approach manages both technical and financial risks while allowing the organization to develop expertise progressively. For more insights on sustainable practices, explore the best zero-waste disposal methods.

Starting Your Shell Recycling Business

Turning the concept of shell waste recycling into a viable business requires methodical planning and execution. The following five-step framework provides a roadmap for entrepreneurs entering this space, based on the experiences of successful ventures in various shell recycling segments.

Step 1: Identify Your Shell Source and Supply Chain

Before investing in processing equipment or facility space, secure reliable sources of shell waste. The ideal source provides consistent volume, quality, and composition while minimizing transportation costs. Large seafood processors offer concentrated volumes but may already have existing relationships with recyclers. Restaurant clusters in urban areas provide diverse shell types but require more complex collection logistics. Conducting a detailed supply mapping exercise within your target region will reveal the most promising opportunities and potential constraints.

Consider seasonal fluctuations in supply, particularly if targeting specific shell types like oysters or blue crabs that have distinct harvesting seasons. Your business model must accommodate these natural cycles through inventory management, diversified sourcing, or complementary processing activities during low-volume periods.

Step 2: Select Appropriate Processing Technology

Processing technology selection should balance capital investment against product value and market opportunity. Basic crushing and grinding equipment for agricultural applications might require $50,000-$200,000 in initial investment, while sophisticated chitin extraction facilities can exceed $2 million. Start with technology matched to both your capital resources and identified market opportunities, with plans for incremental upgrades as the business grows. For more insights, explore various food waste depackaging methods that can complement your processing technology.

Consider equipment versatility when making investment decisions. Some processing systems can handle multiple shell types with minor adjustments, while others are optimized for specific materials. Flexibility typically costs more initially but reduces risk by allowing adaptation to changing supply conditions or market demands.

Step 3: Determine Your Target Market

Successful shell recycling ventures focus on specific markets rather than trying to serve all potential applications simultaneously. Agricultural markets offer accessible entry points with simpler processing requirements but lower margins. Construction materials provide higher volumes but require stringent quality control and regulatory approvals. Specialty markets like cosmetics or pharmaceuticals offer premium pricing but demand sophisticated processing and quality assurance systems. For more insights, explore the top reasons for recycling in various industries.

Your market selection should align with your technical capabilities, capital resources, and regional opportunities. Many successful ventures begin with simpler products for local markets before expanding into more technically demanding applications as they build expertise and capital.

Step 4: Navigate Regulations and Compliance

Regulatory frameworks affecting shell recycling vary significantly by region and end-use application. Operations producing agricultural inputs typically face different requirements than those manufacturing construction materials or extracting compounds for human consumption. At a minimum, most jurisdictions require permits for waste handling, processing facility operation, and product safety certification for specific applications.

Engage early with regulatory authorities to understand requirements and build compliance into your operational planning. Proactive regulatory engagement often reveals potential obstacles before significant investments are made, while also identifying supportive programs like tax incentives or grant funding for waste reduction initiatives.

Step 5: Calculate Start-up Costs and ROI Timeline

Realistic financial modelling is essential for securing investment and setting appropriate expectations. Collection infrastructure typically represents 30-40% of operational costs for shell recycling ventures, with processing equipment, facility costs, and labor comprising the remainder. Revenue projections should consider both initial low-volume operations and future economies of scale, with conservative assumptions about market penetration rates and pricing. For additional insights, explore the top reasons for recycling and how they can impact your business model.

Most successful shell recycling operations achieve positive cash flow within 18-36 months, though higher-value applications may require longer development timelines before generating significant revenue. A phased approach—starting with simpler products while developing more sophisticated offerings—can accelerate initial cash flow while building toward higher-margin opportunities.

Market Opportunities Across Industries

The versatility of shell-derived materials creates opportunities across multiple industries, each with distinct characteristics, requirements, and potential returns. Understanding these market segments helps entrepreneurs identify the most promising applications for their specific circumstances and capabilities.

Agricultural Sector: Soil Amendments and Feed Additives

Agriculture represents the largest potential volume market for processed shells, particularly in regions with acidic soils where calcium amendments improve productivity. Shell-derived calcium carbonate releases more slowly than synthetic alternatives, providing extended benefits while improving soil structure. The organic certification of shell-derived products allows premium pricing in specialized market segments, particularly for operations serving organic growers.

Within animal agriculture, shell-derived calcium supplements for poultry feed command premium prices over mined limestone alternatives due to superior bioavailability and natural origin. The U.S. organic poultry sector alone uses approximately 80,000 tons of calcium supplements annually, creating substantial opportunities for shell-derived alternatives. Regional feed manufacturers represent ideal initial customers, as they purchase in manageable volumes while providing consistent, predictable demand.

“Biogenic calcium carbonate derived from …” from www.frontiersin.org and used with no modifications. Showing the versatility of seafood shell waste recycling.

Construction Industry: Sustainable Building Materials

The construction sector's growing emphasis on sustainable materials creates significant opportunities for shell-derived products. Applications range from simple aggregate replacement in concrete to specialized products like shell-based insulation materials and acoustic panels. The carbon sequestration benefits of shell-incorporated building materials appeal to developers pursuing green building certifications, creating premium pricing opportunities in this rapidly growing segment.

Regulatory support for sustainable construction is accelerating market development, with several jurisdictions now offering incentives for carbon-sequestering building materials. In markets with established green building certification programs like LEED or BREEAM, shell-based materials can help projects earn critical points toward certification thresholds, creating value beyond the materials themselves.

Water Treatment: Natural Filtration Media

The water treatment sector increasingly seeks sustainable alternatives to manufactured filtration media, creating opportunities for shell-based solutions. Municipal wastewater facilities, aquaculture operations, and industrial water treatment systems all represent potential markets for shell-derived filtration media. Performance benefits include improved phosphorus removal, natural pH buffering, and support for beneficial microbial communities that enhance biological filtration processes.

The recurring nature of this market is particularly attractive—filtration media requires periodic replacement, creating ongoing demand rather than one-time purchases. Additionally, spent media often retains value for agricultural applications after its filtration lifecycle, creating secondary revenue opportunities or disposal cost savings.

Healthcare and Cosmetics: Chitin-Based Products

While requiring more sophisticated processing, healthcare and cosmetic applications offer the highest margins for shell-derived materials. Chitosan from crustacean shells has proven applications in wound care, drug delivery systems, and anti-ageing skincare formulations. The natural origin of these materials appeals to consumers increasingly concerned about synthetic ingredients, while their functional properties often outperform petroleum-derived alternatives.

Market entry typically requires partnerships with established players or significant R&D investment to develop proprietary formulations. However, the potential returns justify the investment for ventures with appropriate technical capabilities and patient capital. Several biotech start-ups focused on shell-derived pharmaceutical ingredients have achieved successful exits through acquisition by larger healthcare companies seeking sustainable material innovations.

Frequently Asked Questions

As you explore opportunities in seafood shell recycling, you'll likely encounter common questions from potential investors, partners, and customers. The following responses address these frequently asked questions with practical insights based on industry experience.

What types of seafood shells are most valuable for recycling?

Different shell types offer different value propositions based on their composition and structure. Crustacean shells (crab, shrimp, lobster) contain valuable chitin that can be processed into high-value chitosan for pharmaceutical and cosmetic applications. Bivalve shells (oysters, mussels, clams) consist primarily of calcium carbonate in crystalline structures ideal for agricultural lime, construction materials, and water filtration media.

The most valuable shells for your specific operation will depend on your processing capabilities, target markets, and regional availability. Many successful operations process multiple shell types through parallel or sequential systems to maximize the utilization of available resources while serving diverse markets.

How much does it cost to start a shell recycling business?

Startup costs vary dramatically based on your business model, processing technology, and scale of operations. Small-scale operations focused on agricultural applications can begin with as little as $100,000-$250,000 for basic collection, cleaning, and crushing equipment plus initial working capital.

Mid-scale operations producing multiple product streams typically require $500,000-$1.5 million for more sophisticated processing equipment, facility improvements, and operating capital through the revenue development phase.

Ventures targeting high-value applications like pharmaceutical-grade chitosan extraction typically require $2-5 million in initial capital to fund specialized equipment, laboratory facilities, regulatory compliance, and extended product development timelines. Many successful operations begin with simpler processing for immediate revenue while incrementally adding capabilities for higher-value products as capital and expertise accumulate.

“Our shell recycling operation began with a $175,000 investment in basic processing equipment serving agricultural markets. Five years later, we've invested an additional $800,000 in expanded capabilities but now generate over $1.2 million in annual revenue across three distinct product lines.” – Founder, Northeast Shell Recovery

What regulations apply to processing seafood waste?

Regulatory frameworks vary by location but typically include permits for waste handling, facility operation, and product safety certification. In the United States, state environmental agencies generally oversee waste processing facilities, while the FDA may regulate products intended for animal feed or human-related applications. In the European Union, waste processing falls under national implementations of the EU Waste Framework Directive, with additional requirements for specific end products.

Beyond permits, many jurisdictions impose specific requirements for odour control, wastewater management, and transportation of biological materials. Engaging environmental consultants familiar with local regulations during your planning phase can prevent costly compliance issues later.

Many successful ventures have found that proactive engagement with regulatory authorities often reveals supportive programs like expedited permitting for waste reduction initiatives or technical assistance for compliance planning.

Can small restaurants participate in shell recycling programs?

Small restaurants can absolutely participate in shell recycling programs, particularly through collective models that aggregate volumes across multiple establishments.

Restaurant districts or food service clusters create sufficient density to make collection economically viable, especially when integrated with existing waste management services.

Several successful models operate in coastal regions where seafood restaurants naturally concentrate, using shared collection points or coordinated pickup schedules to achieve efficient logistics.

For restaurants, participation typically involves minimal operational changes—simply separating shells into designated containers and following basic cleanliness guidelines. The primary motivation often combines waste disposal cost savings with sustainability credentials that appeal to environmentally conscious customers.

Some programs provide participating restaurants with promotional materials highlighting their contribution to circular economy initiatives, creating marketing value beyond the direct economic benefits.

Restaurant association partnerships have proven particularly effective for launching collection programs, as they provide established communication channels and collective bargaining power for service arrangements. In several regions, restaurant associations have helped establish shell collection as a standard industry practice, creating reliable, continuous feedstock for processing operations.

How does shell recycling reduce carbon footprint compared to landfill disposal?

Shell recycling delivers carbon benefits through multiple mechanisms compared to conventional disposal. First, diverting shells from landfills prevents methane emissions that occur during the anaerobic decomposition of attached organic materials.

Second, applications like construction materials and soil amendments effectively sequester the calcium carbonate in shells, which contains carbon that would otherwise eventually be released during natural decomposition processes.

Quantitative analyses show that one ton of oyster shells recycled into construction materials can sequester approximately 440 pounds of CO? equivalent, while also avoiding methane emissions equivalent to approximately 113 pounds of CO?. Additional benefits accrue when shell-derived products replace carbon-intensive alternatives—for example when shell-based calcium supplements replace mined limestone that requires energy-intensive extraction and processing.

These carbon benefits create additional value through carbon credit programs in some jurisdictions, potentially generating supplementary revenue streams for recycling operations. Several pioneering ventures have successfully registered their processes under voluntary carbon offset protocols, creating verified carbon credits that can be sold to companies seeking to offset their emissions.

Our Opinion of Seafood Shell Waste Recycling as a Business Opportunity

Shellfish waste recycling represents one of those rare business opportunities where environmental benefits align perfectly with economic potential. As regulations tighten and consumers increasingly demand sustainable practices, entrepreneurs who develop efficient systems for transforming this “waste” into valuable products will find themselves at the forefront of the circular economy revolution.

Companies can start small with a relatively low initial investment in simple shell collection plus cleaning and grinding machinery, and progress to developing higher value products as the company matures.

To learn more about implementing shell recycling programs or investing in this growing sector, visit xxxxxx for a more in-depth review of industry insights and partnership opportunities.