In this article, we describe what we believe makes a good depackaging machine right now.

Machines of this type have been in use for about 40 years, but most are first-generation machines that produce an unacceptable microplastic burden.

We discuss why this needs to stop while also taking a general view of the design of these machines in an era where efficiency and sustainability are paramount, and the role of depackaging machines in recycling and waste management processes has become increasingly critical.

The latest of these are sophisticated devices designed to separate materials from their packaging cleanly without smashing everything into tiny pieces, enabling the recycling of resources, including plastics, for the first time and drastically reducing the volume of organic waste sent to landfills.

As we venture into 2024, understanding the characteristics and features that define a good depackaging machine is essential for industries aiming to enhance their operational efficiency and environmental footprint.

Introduction

Definition of Depackaging Machines

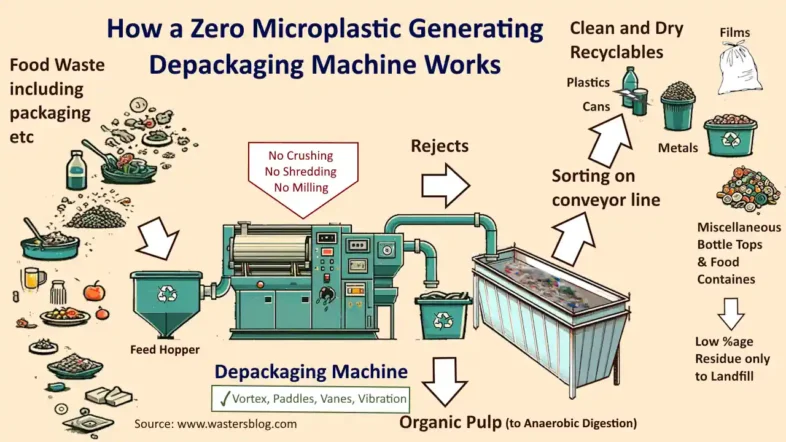

Once packaging removal has been performed, the current generation of these machines goes on to separate:

- the organic content that is generally sent to a biogas plant (often called the “pulp” or “soup”)

- from the other materials (known as “rejects”).

At the biogas plant, it is digested for energy extraction in the form of methane gas, and increasingly, purified to become “biomethane,” a renewable fuel for transport use and a natural gas substitute.

The challenge is to produce a clean and dry reject stream/output that can avoid the ignominious classification of waste, and, after further sorting, be sold as products for their value as recyclable materials.

The Microplastic Pollution Problem

The original depackaging and separation machines were modified shredding and milling machines, and most of those are still in use in the recycling centres of the developed nations of Europe.

But that has become a major problem.

It has only recently been appreciated that the large quantities of tiny plastic particles (microplastics) that these “particle size reduction” processes use are contributing to the worrying plastic pollution of land and the oceans.

Therefore, any good depackaging machine in 2024 will operate an alternative process that avoids “particle size reduction.” As it turns out, that necessity has resulted in an asset.

“Particle size reduction, with the little pieces it produces, was never going to be suitable for modern smart sorting technologies.”

An infographic showing – How a Depackaging Machine Works.

Ballistic Separation of Valuable Resins

The larger particle size makes recycling much easier when rags and bottles are plucked out whole, or in large pieces when seen by the conveyor-belt mounted cameras used to distinguish valuable plastic resins (HDPE, PET, etc.) and spit them out ballistically into separate bins, segregating profitable plastics from the less readily recyclable.

Equally, metal pieces are sorted from the latest minimum impact depackaging machines using magnets and induction techniques, which are simply not amicable to the much smaller particles from the original design of “shredding and milling” depackagers.

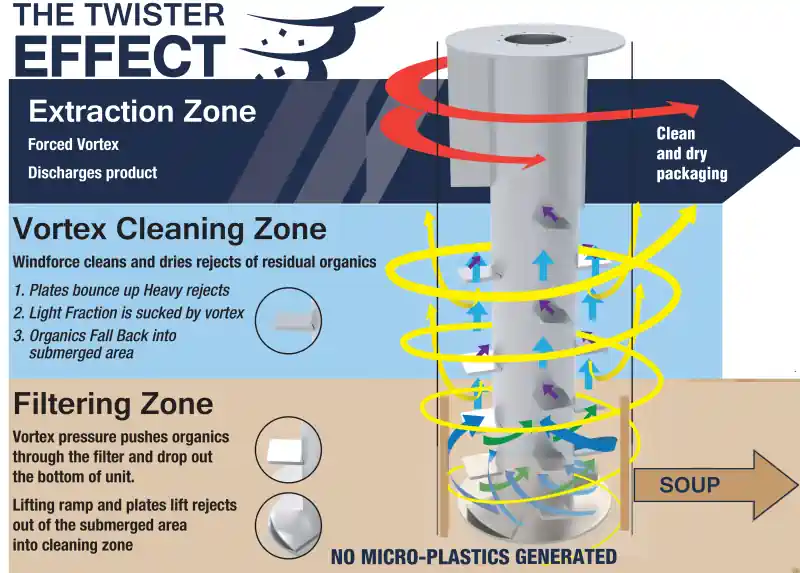

An example of a depackaging machine that is reputed to add zero microplastic fragments while producing an optimum organic pulp output, is the Twister™ Depackager illustrated below.

Importance of Depackaging Machines in Various Industries

These machines play a crucial role across numerous sectors, including food and beverage, pharmaceuticals, and, above all, food waste recycling businesses.

By efficiently separating products from their packaging, they not only streamline recycling processes but also contribute to the reduction of landfill waste, underpinning efforts towards diverting food waste from landfills, and more sustainable waste management practices.

Overview of the Best Features of Depackaging Machines

A top-tier depackaging machine in 2024 will be characterized by several key features: efficiency, versatility, zero microplastic creation, safety, durability, and user-friendliness. These attributes ensure that the machine can meet the diverse needs of the organic waste processing sector while promoting a safe and sustainable working environment.

Efficiency

High Processing Speed

The ability to process materials quickly without compromising the quality of separation is a hallmark of a superior depackaging machine. High-speed operations are essential for meeting the demands of large-scale industrial applications.

Ability to Handle a Wide Range of Packaging Types

From rigid containers to flexible wrappers, a good depackaging machine can accommodate a broad spectrum of packaging materials, thereby enhancing its utility across different sectors.

Depackaging Brands that Offer Zero Microplastic Creation

- exclusively use rotating, paddles, air vortex separation, and other non-microplastic producing methods,

- while also not employing shredding or milling in their processes,

during our research for this article.

This has led us to conclude that specific information for each brand and model is not currently readily available in searches.

For many brands, detailed information about their operational mechanisms is only available directly from their manufacturers or may possibly be found in expensive specialized industry reports.

For accurate and up-to-date information on such specific equipment, it is recommended to contact manufacturers directly.

Some manufacturers have begun to offer equipment to remove microplastics and other foreign particles after particle size reduction but they continue to offer outdated machines that still create these particles.

As far as we are aware only Drycake Twister offers zero microplastic creation in their products.

Minimal Downtime for Maintenance and Cleaning

Downtime can significantly affect operational efficiency. Thus, machines designed for easy maintenance and quick cleaning without extensive shutdowns are highly valued.

Versatility

Ability to Process Different Types of Materials

A versatile depackaging machine can handle various materials, such as plastic, glass, and metal, making it indispensable in a multi-material recycling process.

Flexibility to Adjust Settings for Various Packaging Sizes

The capability to adapt to different packaging sizes without requiring extensive manual adjustments is another critical feature, ensuring seamless operation across a range of products.

Compatibility with Different Industries and Applications

The best depackaging machines are those that can be integrated into various industrial processes, from waste management to product recovery, demonstrating their adaptability and broad application scope.

Low Cost of Ownership

Low Energy Consumption

This is particularly important with current high energy prices.

Few Moving Parts

Keeping the number of moving parts to a minimum keeps maintenance costs low. Bearings need to be few in number and quick to replace.

Long Servicing Interval

Always an important cost factor.

Low Footprint

Space is always at a premium, with the smallest model footprint preferred.

Easy Access for Cleaning

The simpler the unit construction, the better, with rapid removal of all parts to enable access to all components for maintenance

Safety

Implementation of Safety Sensors and Alarms

Incorporating advanced safety features, such as sensors and alarms, minimizes the risk of accidents, protecting both operators and machinery.

Enclosed Design to Prevent Accidents

An enclosed design not only safeguards the operators but also ensures the integrity of the materials being processed, preventing contamination and spillage.

Compliance with Industry Standards and Regulations

Adherence to safety and environmental regulations is non-negotiable, with the best machines meeting or exceeding these standards to ensure safe and compliant operations.

Potential Health Risk from Atmospheric Microplastic in Plastic Recycling Facilities

Some researchers have highlighted concern for workers inhaling microplastic in the workplace.

It is recommended that air quality monitoring regulations include observation of atmospheric MP [microplastic] in PRFs [plastic recycling facilities] in the future (Enyoh et al., 2022; Kabir et al., 2021; Lithner et al., 2021). Following the precautionary principle, it is also recommended that any workers present in these PRF conditions wear masks to protect against the high likelihood of inhalation of such MPs. N95 respirators could provide protection against MPs down to sizes of approximately 0.1-0.3?m (Qian et al., 1998).

Source: Brown, E., MacDonald, A., Allen, S., & Allen, D. (2023). The potential for a plastic recycling facility to release microplastic pollution and possible filtration remediation effectiveness. Journal of Hazardous Materials Advances, 1(1). Elsevier. Available from ScienceDirect.com

Durability

Constructed with High-Quality Materials

Durability is a function of construction quality. Machines built with high-grade materials can withstand the rigors of continuous use, reducing the need for frequent replacements.

Resistant to Wear and Tear from Continuous Use

Resistance to wear and tear extends the machine's lifespan and ensures consistent performance, a critical consideration for businesses aiming for long-term operational efficiency.

Long Lifespan with Minimal Need for Repairs

A machine that requires minimal repairs over its lifespan represents a sound investment, reducing operational costs and downtime.

User-friendly

Intuitive Interface for Easy Operation

An intuitive user interface simplifies the learning curve for operators, allowing for more efficient control and monitoring of the depackaging process.

Minimal Training Required for Operators

Machines that are simple and easy to operate reduce the need for extensive training, enabling a more flexible and adaptable workforce.

Easily Accessible Components for Maintenance

Ease of access to components for routine maintenance or unexpected repairs ensures that the machine can be quickly returned to full operational status, minimizing downtime.

Depackaging Machine Basics – Conclusion

As we look to the future, the importance of depackaging machines in achieving sustainable industrial processes cannot be overstated.

The characteristics and features highlighted above, including efficiency, versatility, safety, durability, and user-friendliness—and now also minimum microplastic output-define the benchmarks for top-performing machines in 2024.

By prioritizing these features, industries can not only enhance their operational efficiency but also contribute significantly to environmental conservation efforts. As technology continues to evolve, the ongoing innovation in depackaging machines will undoubtedly play a pivotal role in shaping the future of recycling and waste management.