This article is all about sustainable food waste recycling solutions which can be achieved by eliminating grit and plastics from the organic soup output of the Twister™ and Seditank™ depackaging machinery manufactured, supplied and serviced by the Drycake™ company. The sustainable solutions considered to be the aim of the recycling/ waste processing plant operators are:

- diversion of organic waste from landfills: to reduce the odour of landfilling, and in the long term reduce the greenhouse gas which they produce which contributes to global warming

- efficient organic pulp production for high biogas output in AD plants, from food and similar organic waste streams

- use of digestate as a beneficial fertiliser in products for sale.

In the realm of food waste recycling, these sustainable practices are key to minimizing environmental impact and maximizing resource efficiency.

One of the major challenges faced by depackaging equipment operators is the presence of grit and plastics in the organic waste stream. This can lead to maintenance issues and compromise the quality of the final digestate reducing its value as a biogas plant feedstock.

However, with the introduction of the Drycake Seditank system combined with their Plastifloat plastics removal technology, such concerns can now be effectively addressed.

Not only that, but a real opportunity for income generation also arises from:

- the added value of the biogas plant feed (pulp) which is clean from plastic and grit and delivered to the digester at optimum water content

- the potential for the sale of plastic bottles and other selected high-value recyclable plastic waste streams for recycled resin production.

In this article, we will explore the role of the Seditank in eliminating grit and plastics from the organic soup output of the Twister, or any other depackaging machine, and how it contributes to sustainable food waste recycling solutions.

The Problem of Grit and Plastics in Organic Waste

When it comes to food waste recycling, the presence of grit and plastics poses a problem.

Grit, which includes sand, soil, and other heavy inert materials, can cause abrasion and wear in biogas reactors, leading to increased maintenance costs. Moreover, the presence of plastics, including microplastics, not only hampers the efficiency of the digestion process but also raises concerns about:

- raised viscosity in the biogas reactor and

- contamination of the final digestate.

If the depackaging/separation system grinds up metals into tiny pieces, the metal contamination may also be a problem for fertiliser production and will need to be removed with the grit.

Addressing these issues is crucial for achieving sustainable and effective food waste recycling.

Introducing the Seditank

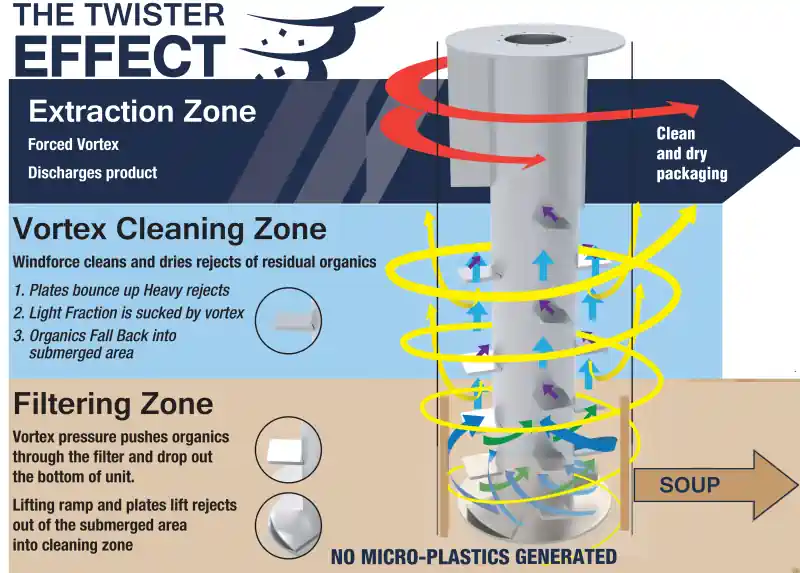

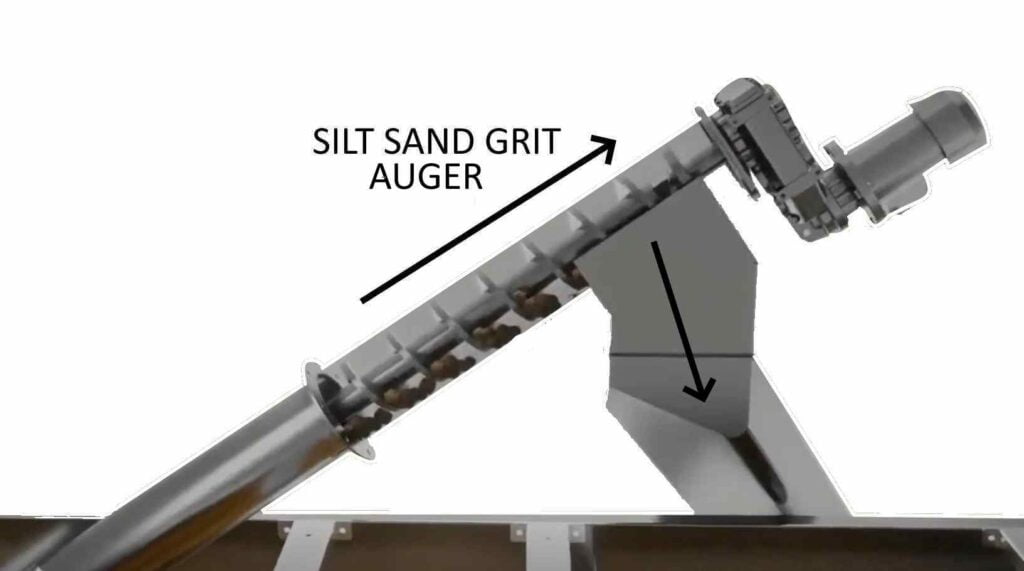

The Seditank is an innovative solution developed by Drycake™ to tackle the problem of grit and plastics in the organic waste stream. It is a piped-in and weir-out/auger-conveyed grit removal system that can be easily integrated with the Twister, or any other depackaging machine. Its function is to remove grit and plastics prior to entering the biogas reactor.

This innovative system eliminates the need for high-wear-resistance grit pumps and enables the efficient separation of organic material from unwanted contaminants.

Enhancing Biogas Yield/Efficiency with the Seditank

The integration of the Seditank with the Twister offers numerous benefits to food processing professionals involved in recycling.

Firstly, by removing grit and plastics, it helps to maintain the longevity and performance of biogas reactors, reducing maintenance costs associated with abrasion and wear.

Secondly, the almost total elimination of plastics from the organic soup output ensures a cleaner and higher-quality digestate, which can be utilized as a valuable resource in various applications.

Additionally, by preventing the entry of plastics into the anaerobic digester, the Seditank plays a crucial role in addressing the growing concern about visible plastics in solids or liquids used in crop and horticultural/garden applications.

The Process: Grit and Plastic Removal

The Seditank-Plastifloat system works in conjunction with the Twister or any other depackaging machine to efficiently remove grit and plastics from the organic soup output.

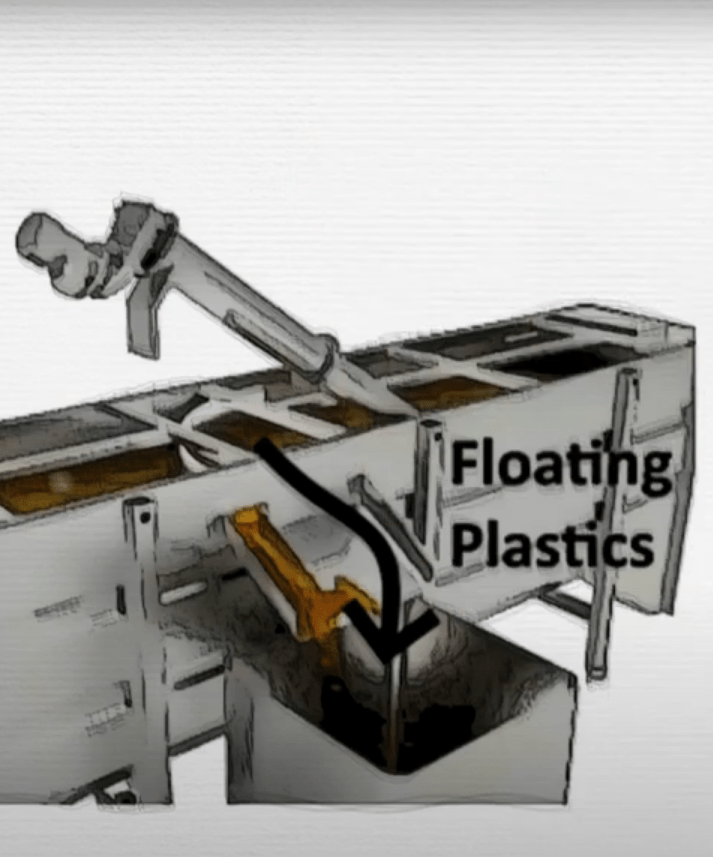

The innovative auto-opening weir outlet, combined with a submerged outlet for the clean pulp, and separate low-level grit/sand/silt outlet allows the 3way separation of light/floating plastics, from the heavy/inert fractions, including grit, from the organics. Only the clean organics then proceed to the biogas reactor.

On the other hand, the Plastifloat component effectively removes all types of plastics, including microplastics, through a specialized separation process. This ensures that the organic waste stream entering the biogas reactor is free from undesirable contaminants, resulting in enhanced system efficiency and a higher quality of digestate.

According to local regulations, the digestate will normally be low in metal contamination and contain minimal microplastic making it suitable for land spreading and use in fertiliser products.

Promoting Sustainable Food Waste Recycling

By incorporating the Seditank system into food waste recycling processes, recycling and food processing professionals can significantly contribute to sustainable practices.

The efficient removal of grit and plastics not only reduces maintenance costs but also safeguards the environment by minimizing the release of microplastics and ensuring a cleaner digestate. Furthermore, the separated plastics can be reprocessed, promoting a circular economy approach and reducing the overall environmental footprint.

The Seditank: A Conclusion

The Seditank system offers a sustainable and efficient solution to the challenges posed by grit and plastics in organic waste recycling.

By seamlessly integrating with the Twister or any other depackaging machine, it eliminates these contaminants from the organic soup output, ensuring the longevity and performance of biogas reactors while producing a higher-quality digestate. Recycling and food processing professionals can rely on the Seditank to promote sustainable practices, reduce maintenance costs, and contribute to a cleaner environment.

With its ability to remove grit and plastics effectively, the Seditank paves the way for a more efficient and eco-friendly food waste recycling process.

Overall, the Seditank system's impact goes beyond simply eliminating grit and plastics. It plays a crucial role in advancing the principles of circular economy and resource efficiency.

By reprocessing the separated plastics, the system promotes a closed-loop approach, reducing the demand for virgin materials and minimizing waste generation.

Through the adoption of the Seditank system, recycling and food processing professionals can lead the way in sustainable food waste recycling, creating a positive impact on both their operations and the environment.

Through the adoption of the Seditank system, recycling and food processing professionals can lead the way in sustainable food waste recycling, creating a positive impact on both their operations and the environment.

Investing in sustainable solutions like the Seditank demonstrates a commitment to responsible waste management and environmental stewardship.

As the demand for effective food waste recycling grows, the Seditank stands as a reliable and innovative tool, empowering professionals in the industry to overcome the challenges of both grit and plastics and contributing to a greener, more sustainable future.

FAQ: Sustainable Food Waste Recycling Solutions with the Seditank System

1. What is the main focus of this article?

This article primarily discusses sustainable food waste recycling solutions with the use of Twister™ and Seditank™ depackaging machinery provided by the Drycake™ company. It elaborates on the role of the Seditank in removing grit and plastics from the organic soup output of the Twister and contributes to sustainable practices.

2. What are the sustainable solutions aimed at by recycling/waste processing plant operators?

They focus on diverting organic waste from landfills, efficiently producing organic pulp for high biogas output, and using digestate as a beneficial fertilizer for sale.

3. Why is the presence of grit and plastics in the organic waste stream problematic?

Grit can cause abrasion in biogas reactors, leading to increased maintenance costs. Plastics, including microplastics, can hinder the efficiency of the digestion process and contaminate the final digestate.

4. How does the Drycake Seditank system help address these challenges?

The Seditank is designed to remove grit and plastics from the organic waste stream before it enters the biogas reactor. This minimizes abrasion, reduces contamination, and ensures a higher-quality digestate.

5. What are the additional benefits of using the Seditank system?

It promotes the longevity and performance of biogas reactors, offers a potential income stream from selling separated plastics for recycled resin production, and supports the principles of the circular economy.

6. Can the Seditank system work with machines other than the Twister?

Yes, the Seditank can be integrated with the Twister or any other depackaging machine.

7. How does the Seditank-Plastifloat system ensure the efficient removal of lightweight and plastic contaminants?

It utilizes an innovative auto-opening weir outlet combined with a submerged outlet for clean pulp. This system allows for the separation of plastics, heavy fractions (like grit), and organics. The Plastifloat component specifically removes all types of plastics, ensuring a contaminant-free organic waste stream.

8. How does the Seditank system contribute to environmental sustainability?

It reduces maintenance costs, minimizes the release of microplastics, ensures a cleaner digestate, promotes a circular economy approach by reprocessing separated plastics and reduces the overall environmental footprint.

9. What does the adoption of the Seditank system signify for recycling and food processing professionals?

It signifies a commitment to sustainable food waste recycling, responsible waste management, and environmental stewardship while overcoming challenges posed by grit and plastics.

10. In conclusion, why should professionals invest in the Seditank system?

It offers a sustainable solution to challenges in organic waste recycling.

By removing grit and plastics, it ensures efficient biogas reactor performance and high-quality digestate. The system promotes sustainable practices, reduces costs, and has a positive environmental impact, thereby signifying a commitment to a greener future.

I can take all your plastic and divert it from landfill and recycle every atom into a non plastic useful bi products. contact me please for further information.