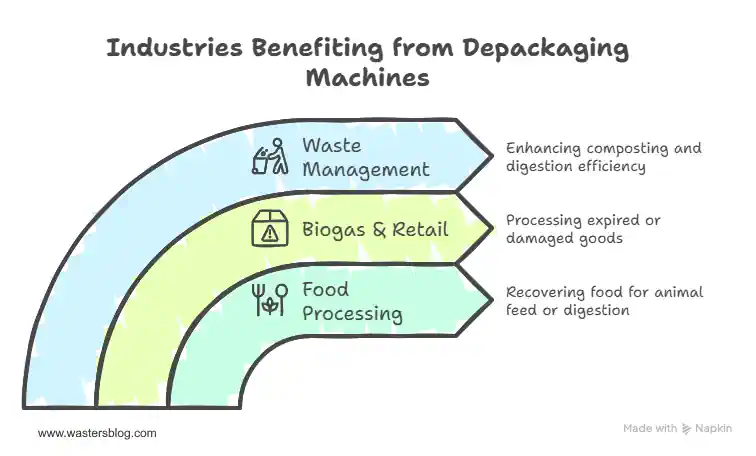

A growing number of food waste depackaging methods are also suited for non-source-separated biodegradable municipal garbage (BMW). Increases in organic waste recycling are becoming increasingly common as a means of preventing this material from ending up in landfills and complying with the COP26 obligations made by so many countries to decarbonize their economy, according to the latest research.

It is inevitable that the purity of source-separated organics (SSO) will be less than 100%, and in certain cases, substantially less, regardless of how well-trained the employees involved in the source separation of food waste are.

Food Waste Depackaging Systems

These systems separate packaging from biological trash by the use of mechanical separation. The packaging is gathered and fed into a compactor, after which it is either disposed of or recycled, if that is possible. Organic waste is either collected in tankers or is immediately fed into a biogas digester or composting facility, depending on the type of waste.

The best Food Waste Depackaging Systems reliably and swiftly separate organic packing materials from non-organic packaging materials, including packaging materials such as plastics and paper, without compromising quality.

Food waste from the food processing industry, grocery store and restaurant waste streams, as well as any other food items that are suitable for recycling, can all be recycled to create an economically viable and valuable value-added product.

Machines for depackaging and sorting materials

The first and most important responsibility for de-packaging machines and the associated separation equipment is to do the following:

Obtain an organic output with the consistency of pulp or thick soup, as well as a reject stream that is as clean and free of water content as possible.

There will be a wide range of packaging types in the reject stream, but for the vast majority of food waste and mechanically separated organic content (also known as OFMSW), a significant proportion will be plastic in some form.

It is critical to avoid the presence of moisture in the reject stream because moisture-laden content invariably contains calorific organic material, which every biogas plant or compost facility operator will want to see in the pulp, where it will be converted into biogas, which will be a source of profit for the plant operator.

Packaged Food Waste

Depackaging Machines remove the contents of food boxes, packets, tins, drums, sachets, and other containers from the outside containers (wrappings), making it feasible to recover or recycle organic waste rather than having it end up in landfills as waste.

In recent years, the subject of the need to reduce food waste has been increasingly popular among corporations and local governments around the world.

It is not possible to directly feed source-separated food waste into the biogas production process/biogas digester due to the large amount of plastic present in the waste stream. Whatever the source of garbage, whether it is from residents or catering establishments, there is always plastic packaging present, which has a negative impact on digestion if left in place.

It is necessary to open all packaging containers before they are placed in a digester tank, and the water content in both the pulp and rejects (plastics and other materials) outputs must be kept to a bare minimum. All of these conditions must be met in order for appropriate food waste material to be fed into the digester tanks of an anaerobic digestion plant.

Waste Depackaging Machine Equipment Suppliers

There are several different types of food waste depackaging systems available: some utilise a hammermill, while others use a shredding machine to break down the trash. Others employ paddles, while still others employ a squashing and squeezing action. The depackaging situation reminds me a lot of the early days of the automobile industry.

To begin with, each brand of automobile was vastly different. Motor vehicles got increasingly similar over time until we reached the point where each vehicle is powered by a combustion engine, and the foot pedals, steering wheel, and clutch are all identical across the board. Although the repackaging sector may eventually follow suit, the systems currently in use in this area are extremely diverse.

Avoid Microplastics Produced by Highly Destructive Depackaging

Everything is broken and smashed into small pieces by a hammermill, which consumes a lot of energy in the process. Because of the rotation of the hammers, the packaging of food waste is opened, and all materials are broken apart, leaving just the organic material to be strained out of the trash.

Everything is broken and smashed into small pieces by a hammermill, which consumes a lot of energy in the process. Because of the rotation of the hammers, the packaging of food waste is opened, and all materials are broken apart, leaving just the organic material to be strained out of the trash.

The only concern is that because everything has been broken down to such a small size, there is a lot of microplastic in the final mash. That is the most difficult type of plastic to sort and reprocess, as well as the most harmful type of plastic to the environment and species in general.

Machines for the Depackaging of Food Waste

We believe that one of the most significant characteristics of depackaging machines is that they should not be reliant on the method employed by the earliest equipment.

Because of the environmentally dangerous action of increasing microplastic content, which is likely to wind up in the environment at least in part, it should no longer be considered acceptable to use size reduction as an acceptable practice.

Food Waste Pre-treatment Systems

Food waste depackaging equipment should be designed to perform the polar opposite of breaking things up small: break things up large. It should make use of a variety of qualities and less severe pressures in order to open packages more effectively. Breaking open the containers with the centrifuge's alternate tensile and compressive forces, as well as vortex action, are two of the methods employed to break open the containers in the most recent types of this equipment.

These forces can be employed in conjunction with one another to separate solid and liquid substances (for example, restaurant waste). Additionally, the process of utilising these various qualities and switches in a food waste depackaging machine can improve the efficiency of the following AD plants and IVC (In-vessel Composting) activities.

Packaging that is less fragmented

The current generation of purpose-built multi-action food waste depackaging machines is intended to reduce the quantity of fragmented packaging in the food waste stream. The revolving paddles and flails aid in the dismantling of the boxes. The flails and paddles transport the empty packages along the upper side of the processing chamber, and the rejects can be discharged from the output point using either water or air as a cleaning agent.

The current generation of purpose-built multi-action food waste depackaging machines is intended to reduce the quantity of fragmented packaging in the food waste stream. The revolving paddles and flails aid in the dismantling of the boxes. The flails and paddles transport the empty packages along the upper side of the processing chamber, and the rejects can be discharged from the output point using either water or air as a cleaning agent.

For composting facilities that handle similar waste streams, these machines may be well worth the investment because they can reduce contamination removal costs while also opening up new tipping fee prospects for industrial food product depackaging and recycling operations.

The better machines will completely depackage more resilient packaging, such as jars of peanut butter in plastic containers packed within a cardboard box, as the horizontal processing chamber proceeds further down the length of the machine. It is not necessary to add water to a turbo Separator when depackaging food waste because the food waste is already liquefied.

What is the definition of Energy Recovery from SSO?

Energy recovery from municipal waste is the process of converting non-recyclable waste materials and packaging into useable energy in the form of heat, electricity, or fuel, rather than a waste product. There are a multitude of procedures that can be used to do this, including combustion, gasification, pyrolysis, anaerobic digestion, and landfill gas recovery.

An all-in-one depackaging solution

The Cleanaway Separator is a device that separates waste from the environment.

Cleanaway's innovative food waste depackaging method separates liquid from organic material, preparing it for anaerobic digestion. The system is currently in development.

The rotating cylinder at the centre of the machine's operation employs paddles to open and move the packages along the chamber's length and out the top of the chamber. If the packaging is long-lasting, it will be depackaged by splitting, and vibration in some machines aids in the removal of stubborn stuck-on food residue.

A wonderful solution for processing big volumes of packaged food, including restaurant garbage, this is a great option. Despite their modest size and need for maintenance, the depackaging machines have a wide range of capabilities. The method aids in the recovery of precious organic materials that would otherwise be lost.

Source-Separated Organics

An hourly processing capacity of 10 tonnes of packaged food waste is achieved at the Cleanaway facility in Victoria. When fully operational, the device has the capability of collecting up to 99% of the material discarded. The equipment does not process glass in any way whatsoever. During the process, the packaging is squeezed, which causes it to break.

This is done in an entirely separate chamber. The anaerobic digestion process is used to dispose of the residual components once they have been separated.

This technology conserves landfill area while also lowering carbon dioxide and methane emissions from landfills. A depackaging unit will be the most efficient way to recycle your packaging if you already have one installed.

Food waste

Scott Equipment is a company that manufactures and distributes a variety of products.

Scott Equipment's food waste depackaging machines have a horizontally structured chamber with rotating paddles and flails, and they are made of stainless steel. At 400 rpm, these revolving blades begin to break down the packing.

The SSO Model is a horizontally configured machine that employs a hammer to open the empty packages that have been placed in front of it. Units with two different capacities are available for purchase. Each of the two units has a 40-ton capacity, with the smaller unit having a lower flow rate and being able to treat source-separated organics and BMW.

The Dominator is yet another brand that is in charge of depackaging garbage and separating plastic containers and plastic bottles from the contents of the containers and bottles they are contained within.

Various more machines for depackaging and separation are also available

The mission of keeping food products out of landfills can be a challenging one, particularly considering the fact that many meals are wrapped neatly and that some pots and punnets are extremely small in size.

A number of food waste depackaging devices use a hammer and subsequently a screw press to separate the pulp from the solids in packaged foods, and this equipment is available online.

In addition to the use of a hammer, a depackaging machine may employ a mix of physical materials characteristics to pick and classify the incoming objects for sorting and packaging. Using a horizontal or vertical-pressure screw press, a hammermill could be supplied with a counter-rotating dual-auger mixing/feeding hopper, and the liquid could be separated from the solid material (fibres) using a horizontal or vertical-pressure screw press.

One characteristic can be used to break the package, while another set of selectors can be used to empty the packages in a different way.

Drycake's Twister Depackager is a twist on the Traditional Depackager

Drycake's Twister, which combines numerous features to separate the recyclable organic fraction from the non-recyclable organic fraction, is another example. While this may appear to be a difficult process, it is absolutely necessary for proper recycling.

When it comes to depackaging all the different types of food packaging, the most versatile machines use a number of different combinations of these variables.

Waste packaging that has been separated can subsequently be delivered to a recycling facility or sold as recycled construction waste (RDF), resulting in even greater waste reduction while also giving the opportunity to generate additional revenue streams.

A wide range of wet and dry waste products, including food, pharmaceuticals, and municipal rubbish, can be depackaged with this equipment. It is also capable of depackaging tetra packs, tin cans, and plastic bottles.

Tiger Machine

Among the main food waste depackaging machines, the Tiger machine is one of the best. It may serve at the beginning of the AD process. Numerous reference sites use the Tiger in the United Kingdom, and the Tiger is supported by its local distributor, Blue Group. Parts for the Tiger machine are in stock and may be shipped out the same day or the next day for rapid delivery.

In addition, there are no long periods of time between the need for maintenance or repair for the machine, and it may be operated by a group of people, with training available in any language.

Depackaging Systems for Food Waste – A Concluding Statement

Food waste depackaging equipment is used to separate the solid organic material from the packaging used to transport the food waste. Separation of BMW and OFMSW can also be accomplished with the appropriate equipment.

There has been a shift away from a strategy of reducing the particle size of incoming food waste and toward less destructive methods that aim to avoid the production of microplastics, which are becoming more prevalent.

The most up-to-date machinery makes every effort to retain film bags and individual packets as close to entire and intact as possible. While things evacuated are frequently not in their entirety, they are frequently in various fragments rather than being pulverised into unidentifiable shreds and flakes.

Various sorts of selection qualities and characteristics are used in modern equipment to separate the organic fraction from the inorganic fraction. The organic substance cannot be removed unless proper depackaging and separation are performed.

Plastic packaging cannot be recycled without the use of these devices, which is why food waste depackaging machines are essential for the plastic recycling sector. Not only are these units beneficial to the AD process, but the latest generation of this equipment also assists IVC composting plants in accepting packaged foods.

Modern technology allows for a more streamlined operation, which requires less labour to manage the equipment and is more efficient overall. At the same time, the new machinery is beneficial to the environment.

For a complete list of food waste depackaging and separation equipment manufacturers and suppliers, here: www.anaerobic-digestion.com-list

[First published 26 March 2022. Updated June 2025.]