District heating and cooling (DHC) is a system that centrally produces and distributes thermal energy—as either hot water/steam or chilled water—to multiple buildings through a network of insulated underground pipes. This replaces the need for individual boilers or air conditioning units in the buildings it serves and these can be any building; residential, commercial, and industrial properties.

Key Takeaways on the Subject of “What is District Heating and Cooling”

- District Heating and Cooling (DHC) systems can achieve efficiency ratings of up to 80% by utilizing waste heat that would otherwise be lost in conventional power generation.

- Combined Heat and Power (CHP) plants form the backbone of many DHC systems, dramatically reducing carbon emissions compared to separate heating and electricity production.

- Modern DHC networks are evolving to incorporate renewable energy sources like biomass, solar thermal, and geothermal, making them a crucial component in sustainable urban planning.

- There are over 6,000 DHC systems currently operating in Europe, demonstrating the proven viability of this technology for reducing fossil fuel dependence.

- Fifth-generation district energy networks represent the cutting edge of the technology, operating at near-ambient temperatures and enabling two-way energy sharing between buildings.

District heating and cooling systems are revolutionizing urban energy infrastructure, yet remain unfamiliar to many outside of Europe and parts of North America. These centralized systems deliver thermal energy through a network of insulated pipes to multiple buildings, eliminating the need for individual boilers and air conditioning units in each structure. When paired with combined heat and power technology, DHC networks represent one of the most efficient and environmentally friendly approaches to meeting our heating and cooling demands.

We've observed that communities transitioning to district energy systems typically reduce their carbon footprint by 30-50% while providing more reliable thermal comfort to residents. The beauty of these systems lies in their ability to capture and utilize energy that would otherwise be wasted, creating a more circular and sustainable approach to keeping our buildings comfortable year-round.

While DHC systems have been around for over a century, they're experiencing a renaissance as cities worldwide seek practical solutions to reduce emissions and energy costs. Let's explore how these remarkable systems work and why they represent such a promising pathway toward sustainable urban development.

District Heating and Cooling: A Smart Urban Energy Solution

District energy systems serve as the thermal backbone of energy-efficient cities, providing heating and cooling to clusters of buildings from centralized plants through a network of insulated pipes. Unlike traditional individual building systems, DHC networks aggregate thermal demand across diverse buildings with different usage patterns, significantly improving overall efficiency. This approach replaces hundreds or even thousands of individual heating and cooling units with a single, highly optimized system that can be more effectively maintained and upgraded over time. For more on sustainable practices, explore waste management best practices.

The concept dates back to ancient Rome's use of hot water for public baths and under-floor heating systems. However, modern district energy emerged in the late 19th century, with the first commercial district heating system appearing in Lockport, New York in 1877. Today's systems have evolved dramatically, incorporating sophisticated technologies and renewable energy sources that their predecessors could never have imagined.

What makes district energy particularly valuable is its adaptability to local conditions and energy sources. Systems can be powered by virtually any heat source—from natural gas and biomass to geothermal energy, solar thermal collectors, and even recovered waste heat from industrial processes or data centers.

This flexibility creates resilience and allows communities to transition toward renewable energy sources over time without replacing the entire infrastructure. Soon, all of us will know what is District Heating and Cooling.

“District heating – Wikipedia” from en.wikipedia.org and used with no modifications.

How District Heating and Cooling Systems Work: The Core Technology Explained

District energy systems operate on a remarkably straightforward principle: centrally generate thermal energy, distribute it efficiently to multiple buildings, and recover it after use. This simple concept belies the sophisticated engineering that makes modern systems so effective at delivering comfortable indoor environments with minimal energy waste.

Central Energy Plants: The Heart of DHC

At the core of every district energy system sits the central plant—a facility housing the equipment that generates hot water, steam, or chilled water for distribution throughout the network. These plants typically utilize combined heat and power (CHP) technology, large-scale boilers, chillers, heat pumps, or a combination of these technologies. The centralized approach allows for equipment that is not only larger and more efficient than building-scale alternatives but also professionally maintained and operated for optimal performance.

Modern central plants often incorporate multiple generation technologies and energy sources, creating a diverse and resilient supply portfolio. This might include gas-fired CHP units providing baseload capacity, biomass boilers for renewable heat, electric heat pumps to utilize excess renewable electricity, and thermal storage to balance supply and demand. By optimizing this mix of technologies, system operators can minimize both operating costs and environmental impact throughout the year.

Distribution Networks: How Heat and Cold Travel

The distribution network consists of insulated underground pipes that carry thermal energy in the form of hot water, steam, or chilled water from the central plant to connected buildings. These sophisticated pipeline systems are designed to minimize heat loss and maintain precise temperature control over long distances. The most advanced networks employ pre-insulated pipes with built-in leak detection systems and can span many kilometers across urban areas. Learn more about district heating systems and their benefits.

Distribution pipelines typically form a closed loop, with supply pipes delivering thermal energy to buildings and return pipes carrying the cooled water (for heating systems) or warmed water (for cooling systems) back to the central plant for reconditioning. This continuous circulation ensures reliable service while maximizing energy efficiency. In northern European cities like Copenhagen, these underground thermal networks have become as fundamental to urban infrastructure as electrical grids or water systems.

Building Connections: Transfer Stations and Interfaces

Where the district energy network meets individual buildings, specialized equipment called substations or energy transfer stations manages the handoff of thermal energy. These stations contain heat exchangers that transfer heat between the district network and the building's internal systems without mixing the water. Modern substations are compact units that replace conventional boilers and chillers while providing precise control over energy delivery.

Smart substations now incorporate advanced controls that optimize energy delivery based on building demand, weather forecasts, and network conditions. This intelligence at the edge of the network helps balance the entire system and reduces wasted energy. Some newer systems even allow buildings with excess thermal energy (perhaps from solar thermal systems or process heat) to feed energy back into the district network, creating truly bidirectional thermal grids.

- Hydraulic interfaces separate building systems from district networks, preventing cross-contamination

- Temperature sensors and control valves regulate energy flow based on building demands

- Smart meters track energy consumption for accurate billing and system optimization

- Compact designs allow retrofitting in existing mechanical rooms

- Bidirectional capabilities in advanced systems enable buildings to both consume and contribute thermal energy

These building connections represent the critical interface between the district system and end users, ensuring that the efficiency benefits of the centralized approach translate into comfortable, reliable indoor environments. As DHC networks evolve, these connection points are becoming increasingly sophisticated, enabling not just energy delivery but true energy sharing between buildings with complementary thermal needs.

“District heating – Wikipedia” from en.wikipedia.org and used with no modifications.

Combined Heat and Power: The Perfect Partner for DHC

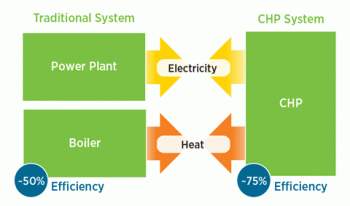

Combined Heat and Power (CHP), also known as cogeneration, forms the backbone of efficient district energy systems worldwide. Unlike conventional power plants that release waste heat into the atmosphere or nearby water bodies, CHP systems capture this thermal energy and put it to productive use. This fundamental difference transforms power generation from a process that typically wastes 50-60% of fuel energy into one that can utilize up to 80-90% of the primary energy input.

When integrated with district energy networks, CHP creates a powerful synergy. The district network provides a ready destination for the recovered heat, while the electrical output powers pumps, chillers, and other equipment needed to operate the thermal distribution system. This integration delivers substantial carbon reductions compared to separate heat and power production, making CHP-powered district energy one of the most cost-effective decarbonization strategies available today.

What Makes CHP Different from Regular Power Plants

Conventional power plants generate electricity by burning fuel to produce high-temperature steam that drives turbines, then discard the remaining low-temperature heat as waste. This fundamental inefficiency means that even the most advanced combined-cycle gas plants achieve only about 60% fuel efficiency. CHP systems, by contrast, are designed from the ground up to capture and utilize this otherwise wasted heat energy, dramatically improving overall energy efficiency. To further understand how innovative technologies are reducing waste, you can explore 5 innovative technologies reducing landfill dependence.

The key innovation in CHP is the strategic positioning of heat recovery equipment within the power generation process. Heat exchangers capture thermal energy from exhaust gases, cooling systems, and other sources within the plant. This recovered heat, which would otherwise be wasted, is then transferred to water or steam for distribution through the district energy network. The result is a system that extracts far more usable energy from each unit of fuel consumed.

Modern CHP plants come in various configurations depending on the primary purpose and available fuels. Some are designed as “power-focused” with electricity as the main product and heat as a valuable byproduct, while others are “heat-focused” with electricity generation secondary to meeting thermal demands. This flexibility allows system designers to optimize for local conditions and priorities while maintaining the core efficiency advantage.

The Efficiency Advantage: Capturing Waste Heat

The efficiency gains from CHP systems are truly remarkable. While conventional separate generation of electricity and heat typically achieves combined efficiencies of 45-55%, well-designed CHP plants regularly achieve total system efficiencies of 75-85%. This dramatic improvement means that for every unit of fuel consumed, CHP systems deliver significantly more usable energy to end users, reducing both costs and environmental impact.

These efficiency benefits translate directly into carbon reductions. Studies consistently show that district heating with CHP offers one of the lowest carbon footprints among all fossil-fuel-based generation options. For cities and communities looking to reduce emissions while maintaining reliable energy services, CHP-powered district energy represents a proven, immediately available solution that doesn't require waiting for future technological breakthroughs.

Fuel Flexibility: What Powers Modern CHP Systems

One of the greatest strengths of CHP technology is its adaptability to various fuel sources. Modern systems can operate on natural gas, biogas, biomass, hydrogen blends, and even municipal or industrial waste. This fuel flexibility provides energy security and allows communities to transition gradually toward renewable energy sources without replacing the entire infrastructure.

Natural gas currently powers the majority of CHP plants due to its relatively clean combustion, widespread availability, and competitive pricing. However, renewable fuels are gaining significant traction. Biomass-powered CHP plants have become common in forest-rich regions like Scandinavia, while biogas from waste treatment facilities and agricultural residues powers an increasing number of systems worldwide. Some pioneering facilities are even beginning to explore hydrogen blending as a pathway to zero-carbon operation.

Key Components of a CHP System

A typical CHP system consists of several core components working together to generate both electricity and usable heat. The prime mover—usually a gas turbine, reciprocating engine, or steam turbine—drives the electrical generator while producing waste heat. Heat recovery equipment then captures this thermal energy from exhaust gases, cooling systems, or steam extraction points. Control systems continuously optimize the balance between electrical and thermal outputs based on demand patterns and operating conditions.

- Prime mover (engine, turbine, fuel cell) that converts fuel to mechanical energy

- Electrical generator that converts mechanical energy to electricity

- Heat recovery system that captures waste heat for productive use

- Control systems that optimize overall performance

- Thermal storage systems that balance supply and demand fluctuations

The U.S. Capitol Building and surrounding congressional facilities demonstrate the practicality of CHP technology even in historically significant settings. These iconic structures are now powered and heated by a modern CHP plant that dramatically reduced both energy costs and environmental impact while improving reliability. This high-profile application highlights how CHP can be successfully integrated even in demanding and sensitive environments.

“District heating – Wikipedia” from en.wikipedia.org and used with no modifications.

Types of District Energy Networks

District energy systems have evolved dramatically over their long history, with each generation of technology offering improved efficiency, flexibility, and environmental performance. Today's systems range from traditional high-temperature steam networks to cutting-edge ambient temperature loops that enable buildings to share energy with each other. Understanding these different approaches helps communities select the most appropriate technology for their specific needs and conditions.

Traditional High-Temperature Steam Systems

The earliest district heating systems, many still operating in older North American cities, distribute energy as high-pressure steam at temperatures exceeding 180°C. These systems excel at delivering large amounts of thermal energy over reasonable distances and can directly supply industrial processes requiring high-temperature steam. Their robust capacity made them the technology of choice for dense urban areas throughout much of the 20th century, particularly in cities with significant industrial activity.

Despite their historical importance, steam systems face significant challenges in modern applications. High operating temperatures increase heat losses throughout the distribution network, reducing overall system efficiency. The high-pressure, high-temperature environment accelerates pipe deterioration and increases safety concerns, leading to higher maintenance requirements. Additionally, steam's poor turndown ratio makes these systems less adaptable to the variable heating demands of modern, well-insulated buildings with diverse usage patterns.

Modern Low-Temperature Hot Water Networks

Most district heating systems built in recent decades use pressurized hot water rather than steam as the distribution medium. These systems typically operate at significantly lower temperatures—generally between 70°C and 120°C—dramatically reducing heat losses and improving overall efficiency. The lower operating temperatures also extend infrastructure lifespan, improve safety, and allow greater integration of renewable and recovered heat sources that cannot achieve steam-level temperatures.

Modern hot water systems incorporate sophisticated pressure and temperature controls that optimize distribution based on outdoor temperatures and actual building demands. During mild weather, system temperatures can be reduced to minimize losses while still meeting heating requirements. The latest generation of these networks operates at even lower temperatures (below 70°C), enabling the efficient integration of heat pumps, solar thermal, and low-grade waste heat sources while still providing effective space heating and domestic hot water production.

District Cooling Systems

District cooling networks distribute chilled water (typically at 4-7°C) to provide air conditioning and process cooling to connected buildings. These systems replace individual chillers and cooling towers with centralized production that achieves economies of scale in both equipment size and operational expertise. The most efficient district cooling systems utilize natural cooling sources like deep lake water, seawater, or river water, drastically reducing electricity consumption compared to conventional air conditioning.

In hot climates or dense urban environments, district cooling offers particularly compelling advantages. By eliminating thousands of individual cooling units and their associated heat rejection, these systems significantly reduce the urban heat island effect while freeing up valuable building space. Many modern developments in the Middle East, Asia, and parts of Europe now incorporate district cooling as a fundamental infrastructure element, recognizing its economic and environmental benefits in high-cooling-demand environments.

Fifth Generation Networks: The Future of DHC

The newest evolution in district energy technology, fifth-generation networks (5GDHC), represents a radical departure from conventional approaches. These systems operate at near-ambient temperatures (15-30°C), drastically reducing distribution losses and enabling simultaneous heating and cooling through decentralized heat pumps. Rather than delivering ready-to-use heating or cooling, these networks provide a thermal energy source that buildings can upgrade or downgrade as needed using their own heat pumps.

What makes 5GDHC truly revolutionary is their bidirectional capability. Buildings can both extract heat from and reject heat into the network, effectively sharing thermal energy between structures with different needs. An office building requiring cooling can reject heat into the network that a nearby residential building can then extract for domestic hot water production. This dynamic energy sharing maximizes overall system efficiency and leverages the diversity of thermal demands across different building types and functions.

Several pioneering projects in Europe, including Mijnwater in the Netherlands and the Drammen district energy system in Norway, demonstrate the potential of this approach. These systems integrate seamlessly with low-temperature heat sources like geothermal wells, water bodies, solar thermal, and ambient waste heat that conventional high-temperature networks cannot effectively utilize. As cities push toward carbon neutrality, these ultra-low temperature networks are likely to become increasingly common in new developments and areas undergoing energy system modernization.

Real-World DHC Success Stories

District energy systems are not merely theoretical concepts but proven solutions operating successfully in cities around the world. These real-world implementations demonstrate the versatility and effectiveness of district energy in diverse climatic, economic, and regulatory environments. From northern European cities with comprehensive systems serving entire urban areas to targeted applications in North America and Asia, these examples provide valuable lessons for communities considering district energy development.

Copenhagen: World Leader in District Heating

Copenhagen's district heating system stands as perhaps the world's most comprehensive example of district energy implementation, serving 98% of the city's heating needs through a vast network of underground pipes. The system evolved from initial waste incineration plants to a sophisticated network incorporating CHP, waste heat recovery, biomass, geothermal, and large-scale heat pumps. This integrated approach has helped Denmark achieve one of the lowest carbon intensities for heating among developed nations while maintaining affordable energy prices for residents.

What makes Copenhagen's system particularly noteworthy is its continuous evolution toward renewable energy sources. Originally developed to improve energy security and reduce oil dependency, the system now serves as a central component of the city's carbon neutrality strategy. Large-scale heat pumps utilizing seawater and wastewater, combined with biomass CHP plants, are progressively replacing fossil fuel inputs. The city's experience demonstrates how district energy infrastructure provides the flexibility to gradually transition energy sources without disrupting service or requiring building-level equipment changes.

Toronto's Deep Lake Water Cooling System

Toronto's innovative Deep Lake Water Cooling system harnesses the naturally cold water of Lake Ontario to provide cooling to the city's downtown. The system draws 4°C water from 83 meters below the lake surface, using it to chill water in the district cooling loop through heat exchangers. This approach reduces electricity consumption for cooling by up to 90% compared to conventional air conditioning systems, eliminating approximately 79,000 tons of carbon dioxide emissions annually.

Beyond its environmental benefits, the system offers compelling economic advantages. Buildings connected to the network eliminate the need for individual cooling towers and chillers, freeing up valuable roof and mechanical space while reducing maintenance requirements. The system also enhances resilience, providing reliable cooling even during electricity disruptions and helping the city manage peak electricity demand during summer heat waves. This successful implementation demonstrates how natural resources can be cleverly leveraged to create district energy solutions uniquely suited to local conditions.

Stockholm's Journey to Fossil-Free District Heating

Stockholm's district heating system illustrates the potential for complete transformation from fossil fuels to renewable energy. Beginning as a conventional system in the 1950s, Stockholm's district heating network has progressively shifted from oil to a diverse mix of energy sources including municipal waste, biomass, large heat pumps utilizing seawater, and recovered heat from data centers. The city now operates one of the world's largest biofuel CHP plants and has effectively eliminated fossil fuels from normal operations, retaining them only as backup during extreme demand periods.

What's particularly instructive about Stockholm's approach is the integration of waste heat recovery from unconventional sources. The city has pioneered agreements with data center operators to recover their waste heat, creating a win-win arrangement that reduces cooling costs for the data centers while providing low-cost heat for the district system. Similar arrangements with industrial facilities and wastewater treatment plants capture energy that would otherwise be wasted. This systematic approach to identifying and utilizing all available thermal resources demonstrates the full potential of district energy as an integrating platform for diverse energy sources.

Environmental and Economic Benefits of DHC

District energy systems deliver a powerful combination of environmental and economic benefits that make them increasingly attractive as communities pursue sustainability goals while managing energy costs. The centralized approach creates economies of scale, operational efficiencies, and fuel flexibility that individual building systems simply cannot match. These advantages translate into tangible benefits for connected buildings, system operators, and the broader community.

Dramatic Carbon Emissions Reduction

District energy systems with CHP can reduce carbon emissions by 30-50% compared to conventional separate heat and power generation, representing one of the most cost-effective carbon reduction strategies available. This efficiency advantage comes primarily from utilizing heat that would otherwise be wasted in conventional power generation, effectively extracting more useful energy from each unit of fuel consumed. Further emissions reductions come from the professional operation and maintenance of centralized equipment, which ensures optimal performance throughout the system's lifetime.

The carbon reduction potential grows even larger when renewable energy sources are incorporated. Biomass, biogas, geothermal, and solar thermal resources that would be impractical to implement at individual building scale become economically viable at district scale. The flexibility to blend multiple energy sources also creates a practical pathway for gradual decarbonization, allowing communities to start with available technologies today while incorporating increasingly renewable inputs as they become available and affordable.

Lower Energy Costs for Communities

Well-designed district energy systems typically deliver heating and cooling at lower costs than individual building solutions when all expenses are considered. The economies of scale in equipment, operations, and maintenance create fundamental cost advantages that grow with system size. Fuel flexibility allows operators to optimize the energy supply mix based on market conditions, while thermal storage enables load shifting to take advantage of time-variable electricity pricing or renewable generation patterns.

For building owners, connecting to district energy eliminates the capital cost of individual heating and cooling equipment while freeing up valuable space previously dedicated to boilers, chillers, and cooling towers. Maintenance responsibilities and equipment replacement costs shift from individual buildings to the system operator, creating more predictable energy expenses and reducing lifecycle costs. Many systems also offer stable, long-term pricing that protects customers from the volatility often associated with individual fuel purchases.

Increased Energy Security and Reliability

District energy networks enhance community resilience by creating fuel flexibility and incorporating multiple heat sources with appropriate backup systems. Unlike individual buildings that typically rely on a single fuel or electricity, district systems can switch between energy sources based on availability and pricing. This adaptability provides protection against supply disruptions affecting any single fuel and allows communities to optimize their energy mix as market conditions evolve.

The professional operation and redundant design of central plants typically deliver superior reliability compared to building-level systems. Continuous monitoring, preventive maintenance, and rapid response capabilities ensure consistent service quality. Many district energy systems maintain N+1 redundancy (extra capacity beyond peak demand) and incorporate thermal storage that can carry the network through short-term generation disruptions. These features make district energy particularly valuable for critical facilities like hospitals, data centers, and emergency response infrastructure.

Waste Heat Recovery from Industrial Processes

District energy networks provide a valuable platform for capturing and utilizing waste heat from industrial processes, data centers, wastewater treatment, and other sources that would otherwise dissipate into the environment. This recovered energy represents a free fuel source that displaces primary energy consumption, creating both economic and environmental benefits. The district network serves as thermal infrastructure that connects waste heat producers with potential users, enabling a more circular approach to energy resources.

Innovative examples of waste heat recovery abound in well-developed district energy markets. In Helsinki, a large data center operates beneath Uspenski Cathedral, with its waste heat captured to warm hundreds of homes. Stockholm recovers heat from data centers, supermarkets, and wastewater treatment plants. Copenhagen captures waste heat from industrial processes including cement production. These applications demonstrate how district energy enables communities to maximize the productive use of all available thermal resources, regardless of their temperature or location. For more information on how waste is managed, check out this waste management guide.

Case Study: Boras, Sweden Waste Heat Recovery

The city of Boras, Sweden demonstrates the remarkable potential of systematic waste heat recovery. Its district heating network captures thermal energy from:

- Municipal waste incineration (primary heat source)

- Textile industry process heat

- Sewage treatment plant operations

- Local manufacturing facilities

- Flue gas condensation from various sources

This integrated approach provides 99.9% of the city's district heating from renewable or recovered sources, demonstrating that with proper infrastructure, communities can dramatically reduce primary energy consumption by recirculating existing thermal energy rather than wasting it.

Renewable Integration: Making DHC Even Greener

While district energy systems offer inherent efficiency advantages regardless of fuel source, their greatest potential lies in facilitating the transition to renewable energy. The centralized approach creates opportunities to incorporate renewable sources that would be impractical at individual building scale, while the thermal network provides valuable flexibility for balancing variable renewable electricity production. These synergies make district energy a critical enabler for comprehensive renewable energy integration at community scale.

Biomass and Biogas CHP Systems

Biomass and biogas represent renewable alternatives to fossil fuels in CHP applications, offering similar dispatchability and reliability while dramatically reducing net carbon emissions. Modern biomass CHP plants utilize wood chips, agricultural residues, or purpose-grown energy crops in highly efficient combustion systems with sophisticated emissions controls. These plants range from small neighborhood-scale facilities serving local networks to large power station conversions like Drax in the UK, which transformed from coal to biomass while continuing to supply its district heating customers.

Biogas from landfills, wastewater treatment, and agricultural waste provides another renewable CHP fuel that leverages existing waste streams. When processed to biomethane standards, this renewable gas can directly replace natural gas in existing CHP facilities, creating a straightforward path to decarbonization without major infrastructure changes. Denmark, Sweden, and Germany have been particularly successful in developing biogas resources for district energy applications, demonstrating the practical viability of this approach at commercial scale.

Geothermal Energy in District Heating

Geothermal energy offers an ideal renewable heat source for district heating networks, providing consistent base-load capacity with minimal operational emissions. While high-temperature geothermal resources suitable for direct use in district heating are geographically limited, advances in geothermal technology are expanding the potential application range. Enhanced geothermal systems (EGS) and medium-depth geothermal wells paired with heat pumps can now provide district heating in regions without natural hot springs or volcanic activity.

Solar Thermal Integration

Large-scale solar thermal installations connected to district heating networks represent one of the most cost-effective solar energy applications. These systems typically use ground-mounted solar collector fields with seasonal thermal storage, allowing summer solar production to meet winter heating demands. Denmark has pioneered this approach, with facilities like Silkeborg's 110 MW solar thermal plant demonstrating that solar can provide a significant portion of district heating even in northern European climates. For those interested in sustainable practices, understanding waste management best practices can further enhance the effectiveness of integrating solar thermal solutions.

Solar district heating economics improve dramatically with scale, as collector costs decrease and operational efficiency increases in large field installations. The centralized approach also enables seasonal thermal storage in large insulated water tanks, underground pit storage, or borehole thermal energy storage (BTES) systems. These storage solutions address solar energy's fundamental timing mismatch with heating demand, creating year-round usability that individual building solar thermal systems rarely achieve.

| Solar District Heating Location | Collector Area | Storage Type | Solar Fraction |

|---|---|---|---|

| Silkeborg, Denmark | 156,694 m² | Network storage | 20% annual |

| Vojens, Denmark | 70,000 m² | 200,000 m³ pit storage | 45% annual |

| Marstal, Denmark | 33,300 m² | 75,000 m³ pit storage | 55% annual |

| Drake Landing, Canada | 2,293 m² | Borehole storage | 95% space heating |

The integration of solar thermal with other renewable heat sources creates particularly effective hybrid systems. In many European installations, biomass provides winter base-load and peak capacity while solar contributes primarily during summer months when biomass boilers would otherwise operate inefficiently at low partial loads. This complementary pairing maximizes the renewable fraction while ensuring reliable year-round operation with minimal fossil fuel backup requirements.

Innovations in solar thermal technology continue to expand its potential applications in district energy. Concentrating solar thermal collectors can produce higher temperatures suitable for industrial processes or absorption cooling, while simplified low-temperature collectors reduce costs for applications like preheating or seasonal ground recharging. These diverse options allow system designers to match solar thermal components to specific network requirements and local climate conditions.

Waste-to-Energy Plants

Modern waste-to-energy facilities provide both electricity and district heating from municipal solid waste that would otherwise occupy landfill space. These plants incorporate sophisticated emissions controls and efficient combustion systems that dramatically reduce environmental impact compared to older incineration technology. When connected to district heating networks, these facilities achieve much higher overall energy recovery efficiency—typically 80-90% compared to 20-30% for waste-to-energy plants producing electricity only. This improved efficiency translates directly to greater landfill diversion and better environmental outcomes per ton of waste processed.

“District heating – thermally insulated pipes – Wikipedia” from en.wikipedia.org and used with no modifications.

Is District Energy Right for Your Community?

While district energy offers compelling advantages, it represents a significant infrastructure investment that requires careful evaluation of local conditions, energy demands, and development patterns. Not every community or development will benefit equally from district energy implementation. Understanding the key factors that influence system viability helps stakeholders make informed decisions about whether and how to pursue district energy development in their specific context.

The most successful district energy implementations typically begin with a comprehensive feasibility study that examines energy demand patterns, available energy sources, regulatory conditions, and financial parameters. This systematic approach identifies opportunities for phased development that can grow organically as the benefits become apparent to additional potential customers. Even when full-scale implementation isn't immediately viable, understanding the potential can inform decisions about preserving corridors, designing buildings for future connection, and avoiding investments that might preclude future district energy development.

Ideal Conditions for DHC Implementation

District energy systems thrive in areas with relatively high density development and diverse building uses that create complementary energy demand patterns. Mixed-use developments where residential buildings (with morning and evening heating peaks) exist alongside offices and commercial spaces (with daytime cooling demands) create excellent load diversity that improves overall system efficiency. Healthcare campuses, university districts, downtown cores, and compact mixed-use neighborhoods typically offer ideal conditions for district energy implementation.

Available local energy resources significantly influence system viability and design. Communities with access to waste heat from industrial processes, geothermal resources, biomass from nearby forestry operations, or suitable conditions for solar thermal have natural advantages for district energy development. Similarly, areas with existing thermal-intensive facilities like hospitals or data centers can use these anchor loads to establish initial system viability, then expand to serve surrounding buildings as the network develops.

Common Barriers and How to Overcome Them

Despite its benefits, district energy faces several common implementation barriers in markets dominated by building-level heating and cooling systems. The high upfront capital cost of distribution infrastructure represents perhaps the greatest challenge, particularly in established areas where underground installation becomes more complicated and expensive. Overcoming this barrier typically requires creative financing approaches, phased development strategies, or public-private partnerships that share costs and risks among multiple stakeholders with different risk profiles and investment horizons.

First Steps Toward a DHC Project

Communities interested in exploring district energy should begin with a high-level screening assessment to identify promising development areas based on energy density, anchor loads, and available energy sources. This initial assessment can determine whether a more detailed feasibility study is warranted and help focus that study on the most promising opportunities. Early engagement with potential major customers, especially those with thermal-intensive operations or approaching equipment replacement cycles, can identify near-term connection opportunities that might anchor initial system development.

Frequently Asked Questions About “What is District Heating and Cooling”

As communities explore district energy options, certain questions consistently arise from stakeholders, building owners, and community members. Addressing these common concerns helps build understanding and support for district energy development while providing practical guidance for decision-makers evaluating potential projects, such as zero waste initiatives.

How much can DHC systems reduce carbon emissions compared to individual heating and cooling?

Well-designed district energy systems with CHP typically reduce carbon emissions by 30-50% compared to conventional separate heat and power production, even when using natural gas as the primary fuel. Systems incorporating renewable energy sources or waste heat recovery can achieve reductions of 50-90% depending on the specific energy mix. These reductions come primarily from higher overall efficiency, the elimination of distribution losses associated with electricity transmission, and the ability to incorporate renewable sources at community scale rather than building scale.

What's the typical payback period for investing in district energy infrastructure?

District energy infrastructure represents a long-term investment with typical payback periods of 8-15 years for the distribution network and 5-10 years for central plant equipment. However, these investments typically deliver returns for 50+ years (for distribution infrastructure) and 20-30 years (for generation equipment). Public or institutional investors often accept these longer paybacks in exchange for the reliable, long-term returns and broader community benefits. Private developers increasingly recognize the value premium for district-connected buildings, which can offset some of the initial investment through enhanced property values.

Can existing buildings be connected to district energy networks?

Absolutely, though the ease and cost of connection varies based on the building's existing systems. Buildings with hydronic (water-based) heating systems like radiators or fan coil units typically connect most easily, requiring only the installation of a heat exchanger and controls to interface with the district system. Buildings with forced air systems may require additional modifications but can usually be connected cost-effectively, especially when existing equipment reaches replacement age. Even buildings with distributed heat pumps or VRF systems can connect through centralized hot/chilled water interfaces that feed the building's internal distribution.

How do DHC systems compare to heat pumps for decarbonization?

District energy systems and heat pumps represent complementary rather than competing approaches to decarbonization. In fact, many modern district systems incorporate large-scale heat pumps as central production equipment, achieving better economies of scale and performance than individual building installations. Fifth-generation district systems essentially create a shared thermal resource that building-level heat pumps can utilize more efficiently than air-source alternatives. The optimal approach depends on local conditions, available energy sources, and development patterns, with many communities implementing hybrid strategies that leverage the strengths of both centralized and distributed approaches.

What government incentives exist for district energy projects?

Government support for district energy varies significantly by country and region, but many jurisdictions offer incentives that recognize the efficiency and environmental benefits of these systems. These include direct grants for feasibility studies or capital costs, low-interest financing through green banks or infrastructure funds, tax incentives for CHP equipment or renewable heat production, and regulatory frameworks that monetize carbon reductions or encourage waste heat recovery. In the U.S., federal programs like the Department of Energy's Technical Assistance Partnerships provide valuable planning support, while various state and utility programs offer financial incentives for efficient district systems.

District heating and cooling systems represent proven, scalable technology that communities worldwide are deploying to reduce emissions, increase energy resilience, and control long-term energy costs. From established systems in European cities to innovative new developments in North America and Asia, these community-scale thermal networks demonstrate the power of thinking beyond individual buildings to create integrated energy systems that serve broader sustainability goals.

As we face the urgent challenge of decarbonizing our built environment, district energy offers a practical pathway that leverages existing technology while remaining adaptable to emerging innovations. By creating thermal infrastructure that can evolve over time, communities implementing district energy today are building flexibility and resilience into their energy systems for decades to come.

For communities seeking sustainable energy solutions that deliver immediate carbon reductions while creating long-term value, Energy Efficiency Solutions provides comprehensive district energy planning, design, and implementation services backed by decades of practical experience.

[Published 15 March 2018. Rewritten October 2025]

U r born for making these articles and videos recycling, waste, trash, excentric things…. All you need to do is. Look for a local utility company that offers a green option. If the service you are using does not offer an alternative, consider switching to another company. Green energy can be a little more expensive but spending a little extra money for the environment is worth it. Besides, you might benefit from tax incentives to cover your expenses. U r awesome

Umm, cant we just, ya know…. Burn it? You are going to kill us all?

So what’s the point of this? This doesn’t tell me much of nothing on how it works.?

If you are in need of district heating solutions for dwellings under your management, Evinox Energy Ltd is here

I LOVE IT!!! COOL IDEAS VERY CREATIVE. THANK YOU.?

Hello, I would be putting your link in our FB page as an informative video about our District Heating. We will also credit your source as well. Thank you!?

Hey,

Really Nice information..

I totally agree with your points..

Thanks for sharing with us..

Keep on posting.