Airport waste management involves a strategic approach to planning for and minimizing the volume of all types of airport waste that are generated. We discuss sorting out airport terminal waste problems including the types of trash encountered, and how the latest minimum impact depackaging equipment is helping.

Introduction to Important Aspects of Airport Waste Management

Airports play a critical role in facilitating global travel, connecting people from different parts of the world. However, with the increasing number of passengers, airports are also generating large amounts of waste, non-hazardous waste but also at times hazardous waste.

Proper management of airport waste is crucial to ensure the safety of passengers, airport staff, and the environment. In particular, the waste left at airport departure gates by passengers who realize they are carrying prohibited liquids is a growing concern for airport waste management.

Every day, thousands of passengers go through security checks at airports worldwide, and quite a few arrive at the departure gate unwittingly carrying prohibited items such as liquids exceeding the allowed limit.

Waste from Discarded Liquids Resulting from Aircraft Security Travel Restrictions

When such items are detected, either during the security check or afterwards these passengers are given the option to dispose of them or go back to check them in. As a result, significant amounts of liquids, including beverages, toiletries, sun tan lotions, and other products, are left behind at airport departure gates.

The proper disposal of these liquids is critical, they are not normally hazardous but they do contain a high organic content and a substantial amount of water. If not disposed of promptly and decomposition and spillage occurs they can pose a threat to airport safety and the environment.

If not managed appropriately, liquids left at airport departure gates can leak, spill, or mix with other waste, leading to contamination and health hazards. Therefore, airports must have proper waste management strategies in place to handle such waste effectively.

In this article, we will explore the importance of proper airport waste management, particularly focusing on the waste left at departure gates by passengers. We will discuss the hazards associated with such waste and the challenges of managing it.

Furthermore, we will look at some of the best practices and solutions adopted by airports worldwide to tackle their organic waste including food waste and waste liquids issues effectively.

Types of Waste

The global air transport industry is predicted to continue its rapid growth, and a by-product of this growth is substantial volumes of waste. To mitigate the environmental impact of this waste and to comply with regulatory requirements, airports are increasingly implementing sustainable waste management policies and systems.

Municipal Solid Waste

The majority of the waste generated at an airport is classified under the umbrella term of municipal solid waste (MSW). MSW compromises all those everyday items such as product packaging, clothing, bottles and food scraps that are discarded after use.

Food Waste

This waste is often collected separately in recycling bins marked for the purpose but, if not, it will be sorted into various feed channels, including recycling and food waste.

Proper sorting saves both time and money by ensuring that recyclables, compostable food waste and special treatment waste are repurposed and not sent to landfill or incineration.

Deplaned waste from domestic and international flights can account for up to 20% of an airport’s total municipal solid waste. This includes discarded passenger beverages, paper, plastic cups and service ware, as well as food waste from meals served onboard.

Recyclable Waste

Airports produce a wide range of waste types, from sewage and solid waste discharges from arriving flights to food production waste from concessionary vendors and airline food production kitchens. Additionally, airports may receive trash from passengers, terminal construction and tarmac areas, or from chemical manufacturers.

One of the most important aspects of airport waste management is ensuring that each type of material ends up in its proper disposal stream. This can be done in a variety of ways, including variations in handling source-separated, and “mixed-waste”, or a combination of both waste collection philosophies.

Recycling options vary at every airport terminal

Recycling options at airports vary depending on tenant agreements, haulier contracts and local regulations.

Some programmes are designed to divert materials from landfills and rely heavily on the incineration of their waste in ERFs (Energy Recovery Facilities) while others are focused on diverting as much as possible of their organic waste from the environment through anaerobic digestion, composting, and recycling especially plastics recycling.

Hazardous Waste

Airport waste management is an essential part of airport operations and should be implemented correctly. Proper practices can lead to significant benefits for the airport, the local community, and the environment.

Hazardous waste is the type of solid waste that contains materials that pose a danger to humans or the environment. This includes toxins and chemicals such as metals contaminated oils, some solvents, and anything that can poison people or cause environmental damage.

The US EPA is just one national body that has strict guidelines for this hazardous waste, and the waste generator must follow strict rules when storing, transporting, disposing, and recycling it.

Deplaned Waste

Deplaned waste is a type of non-hazardous waste that can be handled at airport waste management. This is waste that originates from aircraft flights, such as bottles, cans, newspapers, paper towels, plastic cups, service ware, and food waste.

The quantity of this waste can vary depending on the length of the flight. Long-haul international flights tend to produce more waste than short-haul ones.

Deplaned waste, which includes bottles, cans, newspapers, mixed paper, plastic cups, utensils, service ware and food waste, is hard to separate in a way that allows the plastic content to be recycled due to the degree to which the plastic is dirty from organic content.

To make this easier on airlines and airports, many airports have created collection points near aircraft ramps for deplaned waste. This allows airlines and cabin service crews to transport deplaned materials to recycling containers. This minimizes the need for them to sort mixed waste on the ground and helps reduce labour costs.

Adding Together Airport Waste Types

In addition to the deplaned waste:

- Airports handle a lot of waste, from passengers who purchase food on the go, to restaurants and shop owners keeping inventories and cargo handlers moving goods.

- Liquids in containers are thrown into bins during security checking.

- Liquids in containers in boarding-gate discarded rubbish,

and these high plastic and organic content waste comprise a significant proportion of an airport's municipal solid waste (MSW) stream. Without highly effective means of depackaging this can be a headache for airport managers.

Proper sorting into appropriate feed channels, such as recyclables, compostable and biogas plant digestible food waste with clean separation of all organics from the non-organic municipal solid waste, is essential to:

- reduce landfill costs (and by that also raise the sustainability of airport waste management)

- raise plastic waste recycling rates to meet national targets

- provide good quality organic pulp made from the organic content to be sold as a feedstock to the biogas industry.

Until recently all depackaging equipment relied on size reduction, cutting, hammering and milling the packaging into submission, but that was before naturalists raised the flag on microplastic, to stop the oceans from choking on it.

Airport Terminal Problems Relieved by New Low-Impact Vortex Separation which Keeps Plastic Items Close to Intact

We have discussed the significance of depackaging food waste with efficient energy extraction and minimising environmental impact by selecting the best equipment now available.

But, in the end, solving airport waste problems boils down to combining economic operation with a product (not a waste) output of sufficient purity to allow the sale of outputs with a real market value for energy extraction and material (especially plastics) recycling.

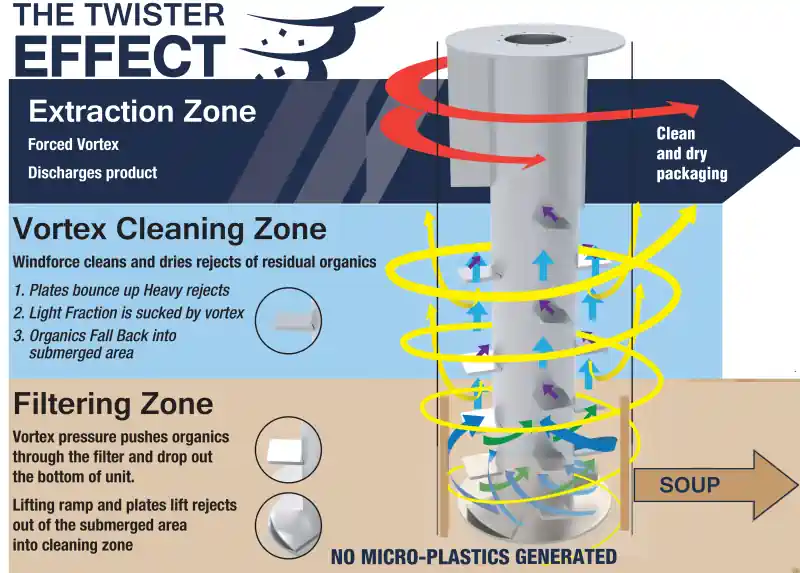

Purity is the key which is unlocked by the innovative separation technology of the Twister depackager.

Purity is defined as the proportion of intended recovered material in the total recovered waste stream (i.e., per cent pure organic pulp in the recovered materials output). Food waste depackager recovery and purity rates achieved by the Drycake Twister Depackaging Machine range to 99%, depending on how much food and moisture remain stuck to the packaging after separation.

Drycake's third-generation vertical vortex separation technology is capable of previously unachievable purity of output from their Twister De-packager and Separator.

This technology is already producing a suitable depackaged organic food waste substrate (pulp) for AD plant feeding at one installation in the United States and close to a dozen elsewhere around the world (Spring 2023).

Twister owners are now selling their “reject stream” materials, after further separation on an MRF sorting line, for energy extraction and/or material recycling including recycling as the reusable plastic resin is now highly in demand.

For example, this equipment operates on source-segregated bakery (biscuit) waste without the addition of any water at one installation in the Czech Republic, and the clean dry output is sold as a valuable animal feed supplement.

The number of installations of this brand of so-called advanced “cutting-edge-equipment” which actually is designed not to cut up and shred, is rapidly increasing. More food waste producers are now, as a result, able to adopt better environmental practices and at last sell the pulp. Finally, they stop dumping their food waste in landfills with other waste or incinerating it at a high cost.

Case Study: Bangalore Airport

Genia Global and Adverio Waste Systems Work Together on Innovative Move Toward Sustainable Management of Air Transport Infrastructure

Bangalore Airport is India's third-largest airport and is known for its sustainability and innovation. It has started a new project to extract energy from food waste and decrease its use of non-renewable energy.

The facility will treat 15,000t of biowaste per year from the airport, producing 2.25 million Nm3/year of biomethane and 14,625MWh of total energy.

This energy will be used to produce both electricity and vehicular biomethane (CNG) to power airport vehicles via its 500kW generator motor.

To accomplish this, a new anaerobic digestion plant and biogas upgrading facility will be constructed on-site to process the waste generated at the airport and during flights.

Adverio Waste Systems, in collaboration with the biogas system provider, chose Twister technology for the task of depackaging waste prior to entering the digester. The ability to produce superior organic outlet quality was cited as the reason.

The Drucake-Twister model used for this project has a capacity of 5 T/hr of bio-waste processing. The commissioning timetable is set for late 2022. Genia Global intends to replicate this model in a number of other airports around the world.